A heat-resistant and wear-resistant composite board and its preparation method

A composite board and wear-resistant alloy technology, applied in the field of composite boards, can solve problems such as uneven heat distribution, poor heat resistance, and shortened service life of composite boards, and achieve good chemical stability, thermal shock resistance, and electrical conductivity Excellent performance and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The invention provides a heat-resistant and wear-resistant composite board, including: a substrate, a wear-resistant alloy plate, a heat-resistant adhesive layer and a wear-resistant coating;

[0026] The heat-resistant adhesive layer includes: 16.0% silicon boron rubber, 13.0% epoxy resin, 0.96% modified nano-antimony tin oxide, 0.86% modified nano-boron nitride, and the rest is ethanol; The wear-resistant coating includes: 1.25% modified silicon carbide whiskers, 0.94% modified nano-titanium diboride, 16.0% epoxy resin, and ethanol as the rest;

[0027] The modified nano-antimony tin oxide, the modified nano-boron nitride, the modified silicon carbide whiskers and the modified nano-titanium diboride are all subjected to surface modification treatment using a vacuum plasma cleaning machine;

[0028] The present invention also provides a method for preparing a heat-resistant and wear-resistant composite board. The specific preparation steps are as follows:

[0029] Ste...

Embodiment 2

[0036] The difference from Example 1 is that the heat-resistant adhesive layer includes: 20.0% silicon boron rubber, 15.0% epoxy resin, 1.64% modified nano antimony tin oxide, 1.74% modified nano Boron nitride and the rest are ethanol; the wear-resistant coating includes: 1.75% modified silicon carbide whiskers, 1.36% modified nano-titanium diboride, 20.0% epoxy resin, and the rest are ethanol.

Embodiment 3

[0038]Different from Examples 1-2, the heat-resistant adhesive layer includes: 18.0% silicon boron rubber, 14.0% epoxy resin, 1.30% modified nano-tin antimony oxide, 1.30% Modified nano boron nitride, the rest is ethanol; the wear-resistant coating includes: 1.50% modified silicon carbide whiskers, 1.15% modified nano titanium diboride, 18.0% epoxy resin , the rest is ethanol.

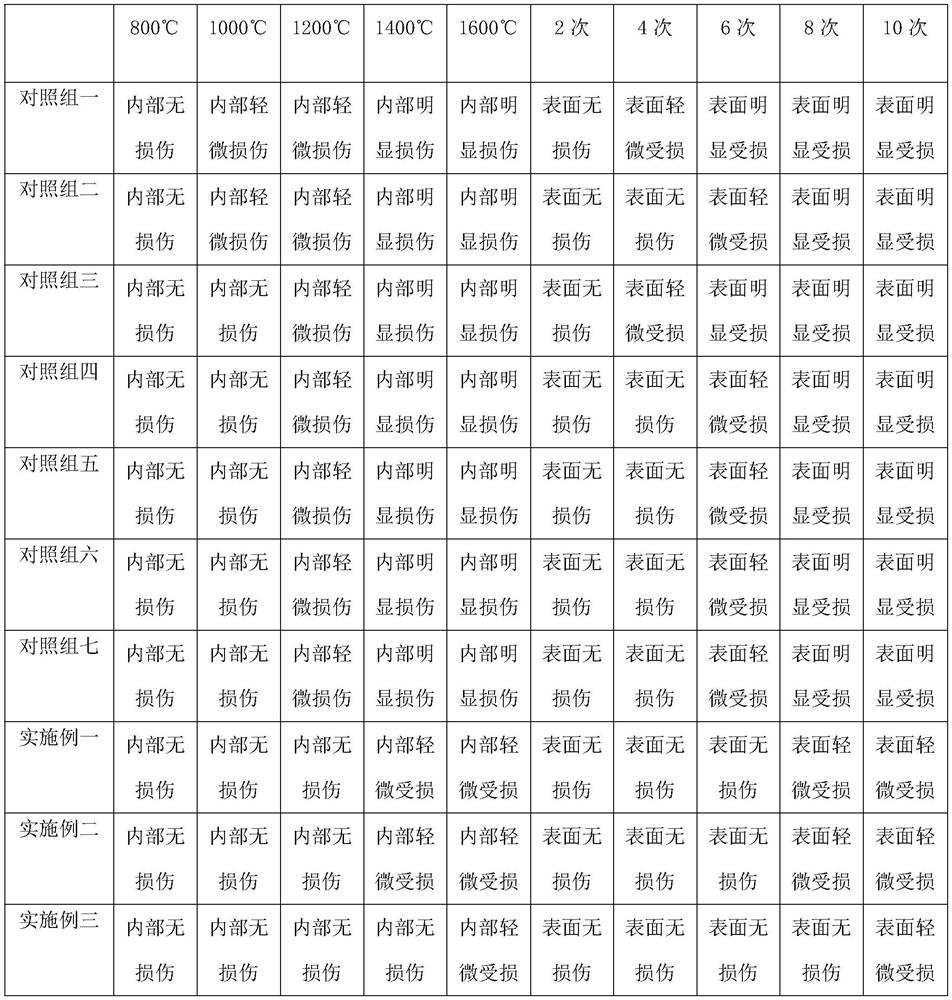

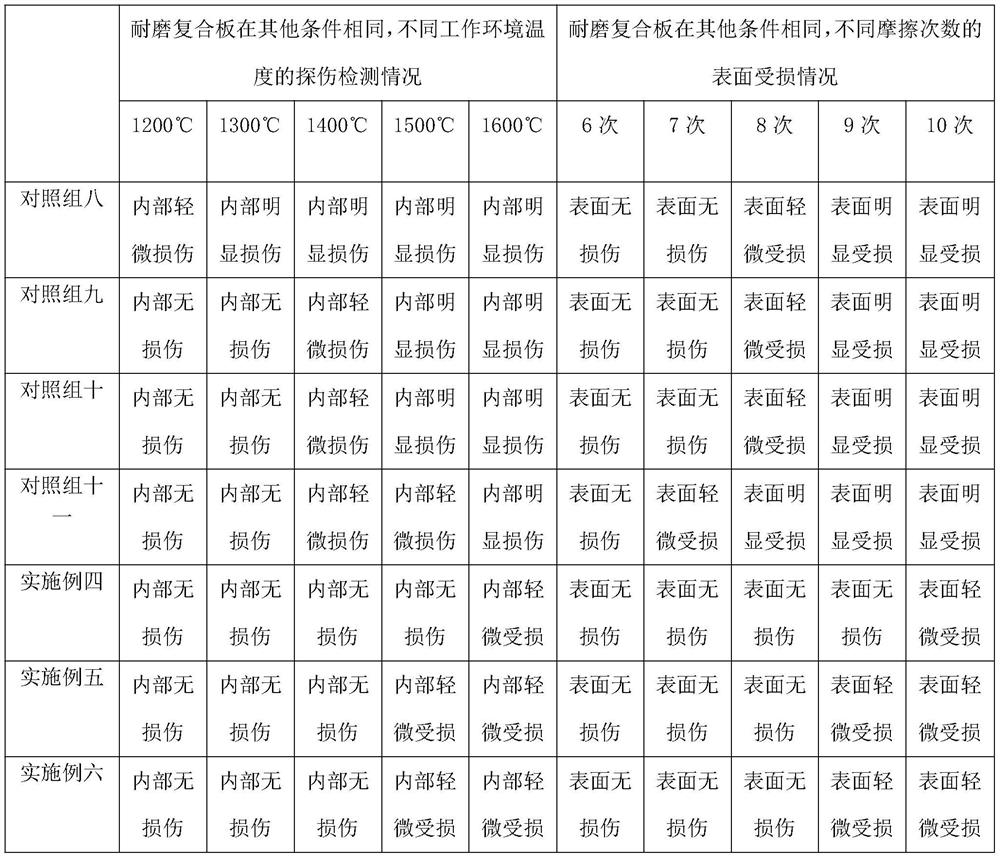

[0039] Take the heat-resistant and wear-resistant composite board obtained in the above-mentioned embodiments 1-3 and the wear-resistant composite board of the control group 1, the wear-resistant composite board of the control group 2, the wear-resistant composite board of the control group 3, respectively. The wear-resistant composite plate of control group 4, the wear-resistant composite plate of control group 5, the wear-resistant composite plate of control group 6, and the wear-resistant composite plate of control group 7 were tested. Compared with no heat-resistant adhesive layer and wear-resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com