Energy-saving safe blasting method for high-temperature blasting

A safe, high-temperature technology, applied in the field of blasting, can solve the problems of affecting blasting effect and safety, large water consumption, non-environmental protection and energy saving, and achieve the effect of preventing the infiltration and loss of cold water, improving environmental performance and reducing water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

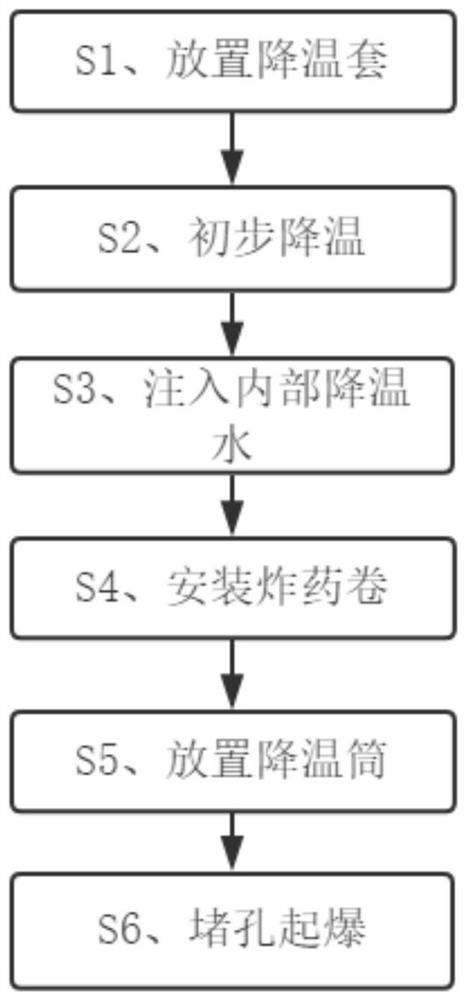

[0047] see Figure 1-6 , an energy-saving and safe blasting method for high-temperature blasting, comprising the following steps:

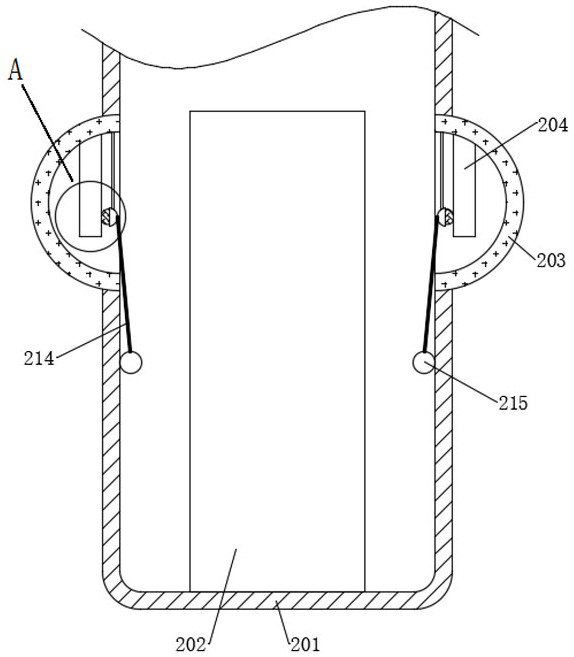

[0048] S1. Place the cooling sleeve: take the heat insulation protection sleeve that matches the blast hole, take out the heat insulation cooling sleeve in the heat insulation protection sleeve from the water retention cooling sleeve 001, and put the water retention cooling sleeve 001 into the blast hole;

[0049] S2. Preliminary cooling: Then inject an appropriate amount of cold water into the water-retaining cooling jacket 001 as preliminary cooling water, and perform preliminary cooling on the blast holes;

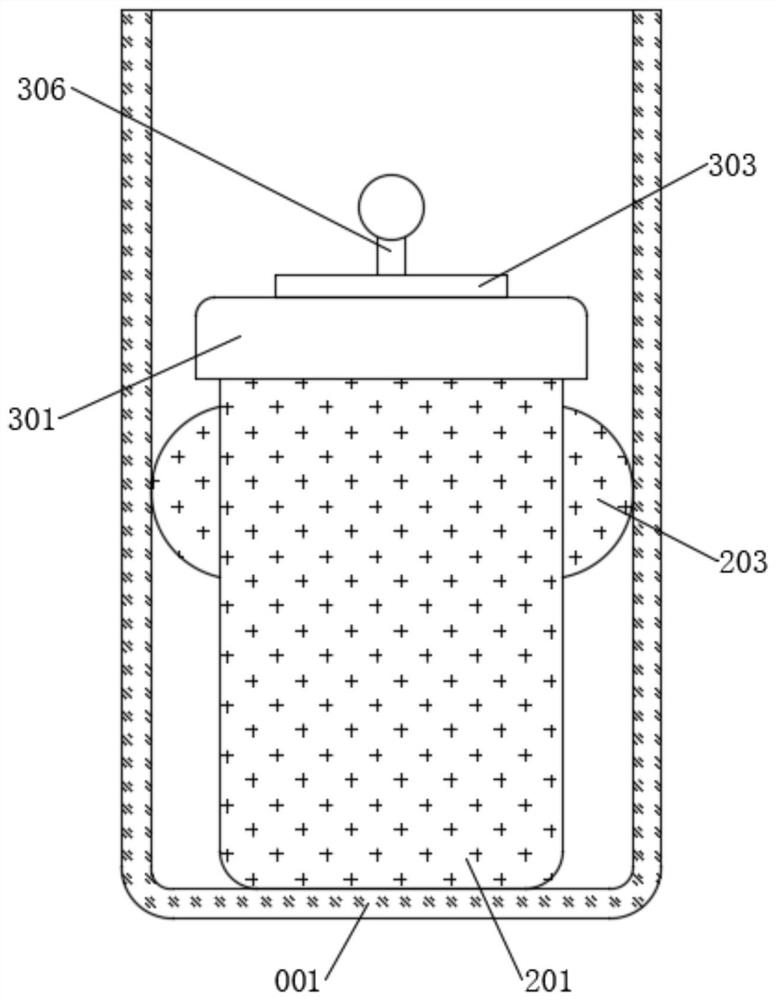

[0050] S3. Injecting internal cooling water: unscrew the heat insulating sealing cover 301 in the heat insulating and cooling cylinder from the heat insulating cylinder 201, and inject an appropriate amount of cold water into the heat insulating cylinder 201 as the internal cooling water;

[0051] S4. Install the explosive roll: put the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com