Carboxyl nano-cellulose and preparation method thereof

A nanocellulose and cellulose technology, applied in the field of carboxyl nanocellulose preparation, can solve problems such as low treatment efficiency in cellulose crystallization area, and achieve the effects of energy saving and environmental protection, secondary aggregation inhibition and cost reduction in the preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

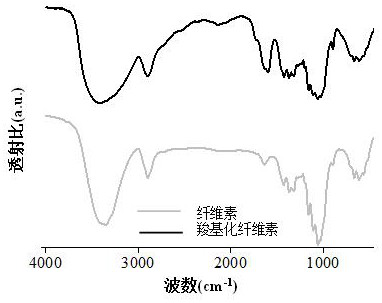

[0018] Embodiment 1: A kind of carboxyl nanocellulose and its preparation method

[0019] Proceed as follows:

[0020] (1) Soak 0.5% (g / mL) bacterial cellulose in pure water overnight at normal temperature and pressure, stir well and add sodium hydroxide solution to ensure that the final concentration of sodium hydroxide solution is 8% (g / mL) , continue stirring;

[0021] (2) Then add bromoacetic acid several times, stir while adding, the total amount added is 70% of the amount fraction of sodium hydroxide substance, continue to stir overnight, add hydrochloric acid solution dropwise to adjust the pH to neutral, after the reaction is terminated Desalination:

[0022] (3) Carboxylated nanocellulose can be obtained by ultrasonically treating the desalted solution.

Embodiment 2

[0023] Embodiment 2: A kind of carboxyl nanocellulose and its preparation method

[0024] Proceed as follows:

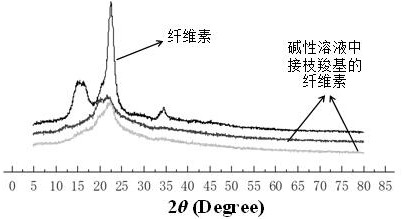

[0025] (1) Soak 2% (g / mL) microcrystalline cellulose in pure water overnight at normal temperature and pressure, stir well and add sodium hydroxide to ensure that the final concentration of sodium hydroxide solution is 12% (g / mL) ;

[0026] (2) Add chloroacetic acid in several times, the amount of the dropwise addition is 70% of the amount of the sodium hydroxide substance, stir while adding, continue to stir for 1 hour after the dropwise addition is completed, then suction filter in the polytetrafluoro funnel, and pass Wash with water several times to remove residual sodium hydroxide and chloroacetic acid on the surface of the cellulose until the conductivity is not greater than 50 μS / cm;

[0027] (3) Carboxyl nanocellulose can be obtained by ball milling.

Embodiment 3

[0028] Embodiment 3: A kind of carboxyl nanocellulose and its preparation method

[0029] Proceed as follows:

[0030] (1) Soak 0.5% (g / mL) eucalyptus pulp in pure water overnight at normal temperature and pressure, stir well and add sodium hydroxide solution to make the final concentration of sodium hydroxide solution 9% (g / mL) ;

[0031] (2) Add iodoacetic acid several times, the amount added is 50% of the amount of sodium hydroxide, continue to stir for 2 hours, add acetic acid solution dropwise to adjust the pH to neutral, and desalt after the reaction is terminated;

[0032] (3) Carboxylated nanocellulose can be obtained by ultrasonic treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com