Environment-friendly thermosetting molding powder and production process thereof

A production process, thermosetting technology, applied in the field of environmentally friendly thermosetting plastic powder and its production process, can solve the problems of high cost, insufficient waterproof, easy to corrode, etc., achieve the improvement of bending resistance and impact performance, and the effect of surface film formation Good, strong waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] An environmentally friendly thermosetting plastic powder, made of the following components by weight: 205 parts of carboxyl polyester resin, 17 parts of triglycidyl isocyanurate, 14 parts of curing agent, 2 parts of leveling agent, and 35 parts of metallic pigment , 1 part of defoamer, 4 parts of luminescent powder, 6 parts of film forming agent and 4 parts of asbestos powder.

[0029] The leveling agent uses polymer compounds such as polyethyl acrylate, polybutyl acrylate, poly-2-ethylhexyl acrylate, ethyl acrylate and butyl acrylate copolymer, and silicone-modified polyacrylate;

[0030] The curing agent is one or more of diethylenetriamine, triethylenetetramine and hydroxyethylethylenediamine;

[0031] The film forming agent is one or more of polyvinyl acetate emulsion, methacrylic acid-acrylic acid copolymer, and polypropylene oxide.

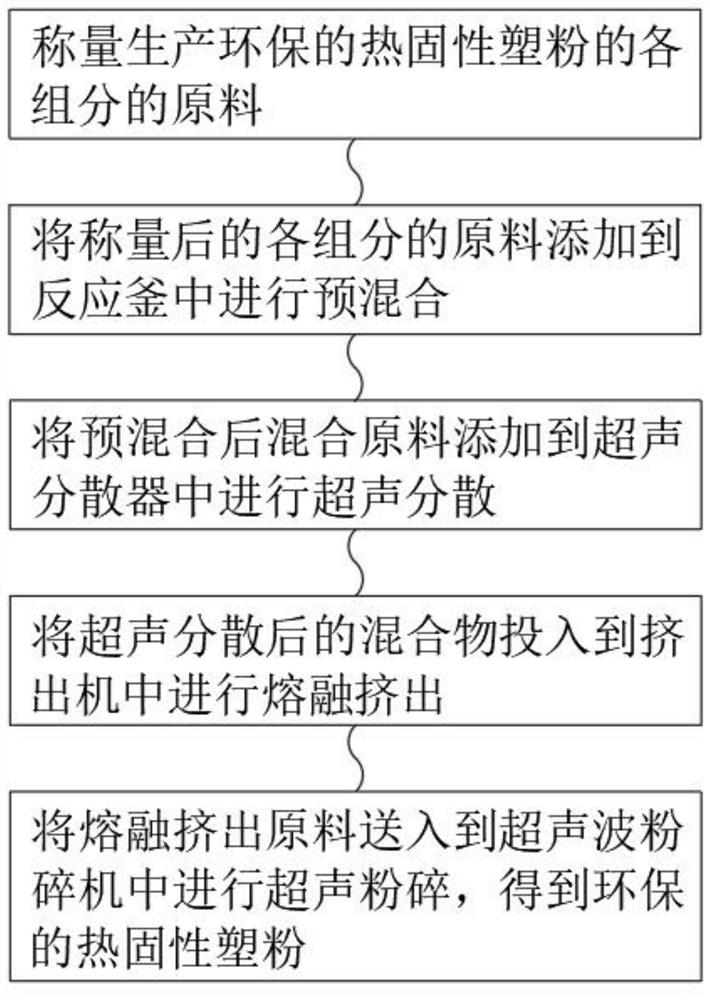

[0032] A production process of environmentally friendly thermosetting plastic powder, comprising the following steps:

[0033] ①. ...

Embodiment 2

[0043] An environmentally friendly thermosetting plastic powder, made of the following components by weight: 210 parts of carboxyl polyester resin, 17 parts of triglycidyl isocyanurate, 15 parts of curing agent, 3 parts of leveling agent, and 40 parts of metallic pigment , 3 parts of defoamer, 6 parts of luminescent powder, 6 parts of film forming agent and 5 parts of asbestos powder.

[0044] The leveling agent uses polymer compounds such as polyethyl acrylate, polybutyl acrylate, poly-2-ethylhexyl acrylate, ethyl acrylate and butyl acrylate copolymer, and silicone-modified polyacrylate;

[0045] The curing agent is one or more of diethylenetriamine, triethylenetetramine and hydroxyethylethylenediamine;

[0046] The film forming agent is one or more of polyvinyl acetate emulsion, methacrylic acid-acrylic acid copolymer, and polypropylene oxide.

[0047] A production process of environmentally friendly thermosetting plastic powder, comprising the following steps:

[0048] ①....

Embodiment 3

[0058] An environmentally friendly thermosetting plastic powder, made of the following components by weight: 220 parts of carboxylated polyester resin, 18 parts of triglycidyl isocyanurate, 17 parts of curing agent, 4 parts of leveling agent, and 36 parts of metallic pigment , 3 parts of defoamer, 9 parts of luminescent powder, 7 parts of film forming agent and 8 parts of asbestos powder.

[0059] The leveling agent uses polymer compounds such as polyethyl acrylate, polybutyl acrylate, poly-2-ethylhexyl acrylate, ethyl acrylate and butyl acrylate copolymer, and silicone-modified polyacrylate;

[0060] The curing agent is one or more of diethylenetriamine, triethylenetetramine and hydroxyethylethylenediamine;

[0061]The film forming agent is one or more of polyvinyl acetate emulsion, methacrylic acid-acrylic acid copolymer, and polypropylene oxide.

[0062] A production process of environmentally friendly thermosetting plastic powder, comprising the following steps:

[0063]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com