A kind of high-strength bulk nanostructure nickel-based alloy and its preparation method

A technology of nickel-based alloys and nanostructures, which is applied in the field of high-strength bulk nanostructured nickel-based alloys and its preparation, can solve problems such as high cost, reduced material performance, and increased strain grains, and achieves low equipment requirements and high production efficiency. The effect of high efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Nickel-based alloys containing dislocations, stacking faults and nano-twins with high yield strength were obtained by rolling treatment. The chemical elements in the nickel-based alloy are measured by atomic percentage (at.%) as follows: Ni: 63.02%, Cr: 27.38%, W: 4.55%, Mo: 1.35%, Co: 1.22%, Mn: 0.52%, Si : 0.60%, Al: 0.60%, Fe: 0.26%, C: 0.47%, P: 0.02%, S: 0.01%.

[0033] The rolling treatment parameters are as follows: the nickel-based alloy is block-shaped, the size is 30mm×15mm×10mm, the rolls work at a speed of 20 r / min, the rolling pressure of each pass is 0.5mm, and 10 passes of rolling are carried out. After rolling, the deformation recovery of the nickel-based alloy is removed, and the rolling deformation is 45%.

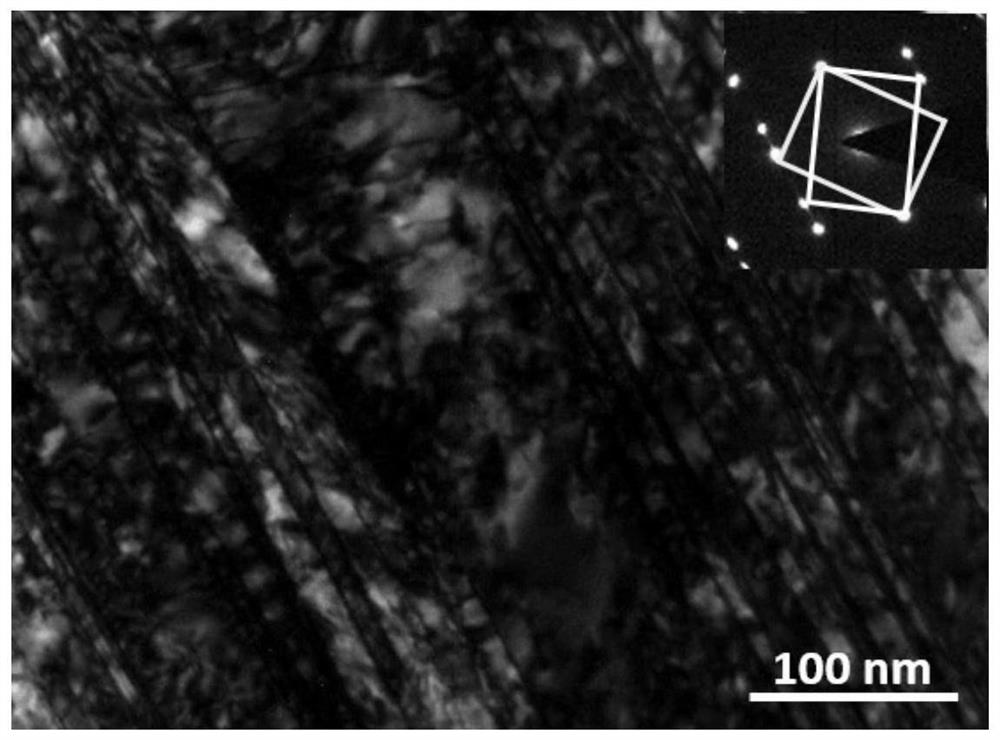

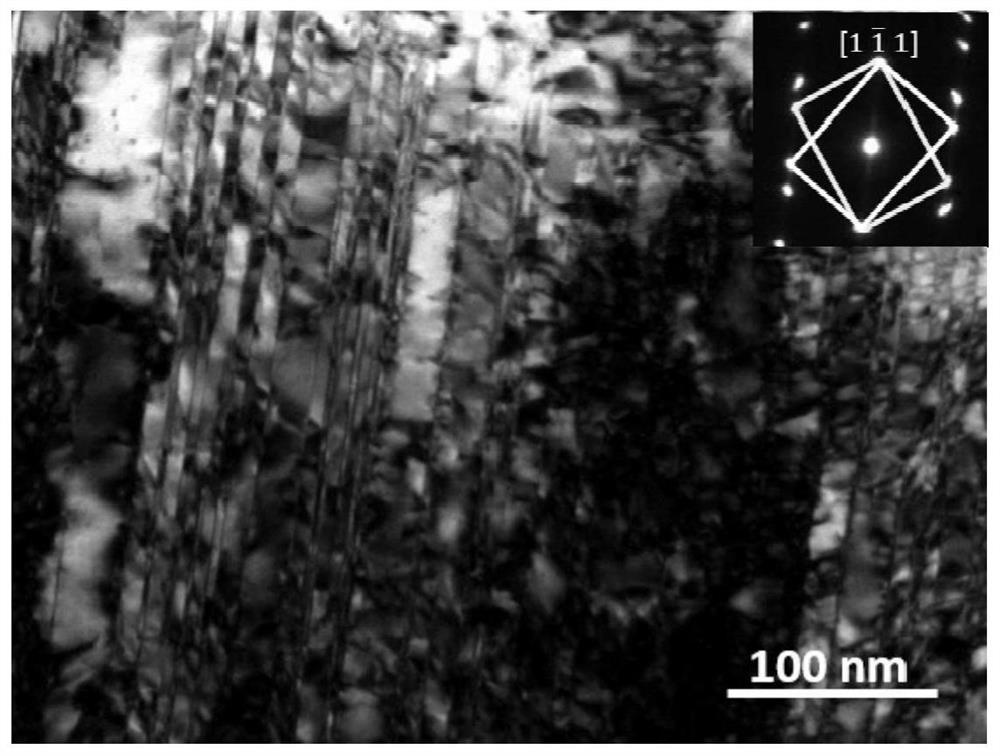

[0034] There are a large number of nano-twin structures in the nickel-based alloy obtained in this example, and the sheets composed of twins and the matrix are full of dislocations and stacking faults, and the average thickness of the sheets compo...

Embodiment 2

[0036] The difference from Example 1 is:

[0037] A nickel-based alloy with high yield strength containing dislocations, stacking faults, nano-twins and nano-crystals is obtained by rolling. The chemical elements in the nickel-based alloy are the same as in Example 1.

[0038] The rolling pressure treatment parameters are as follows: the nickel-based alloy is block-shaped, the size is 30mm×15mm×10mm, the rolls work at a speed of 20r / min, the rolling pressure of each pass is 1mm, and rolling is carried out 9 passes Finally, the deformation recovery of the nickel-based alloy is removed, and the rolling deformation is 80%.

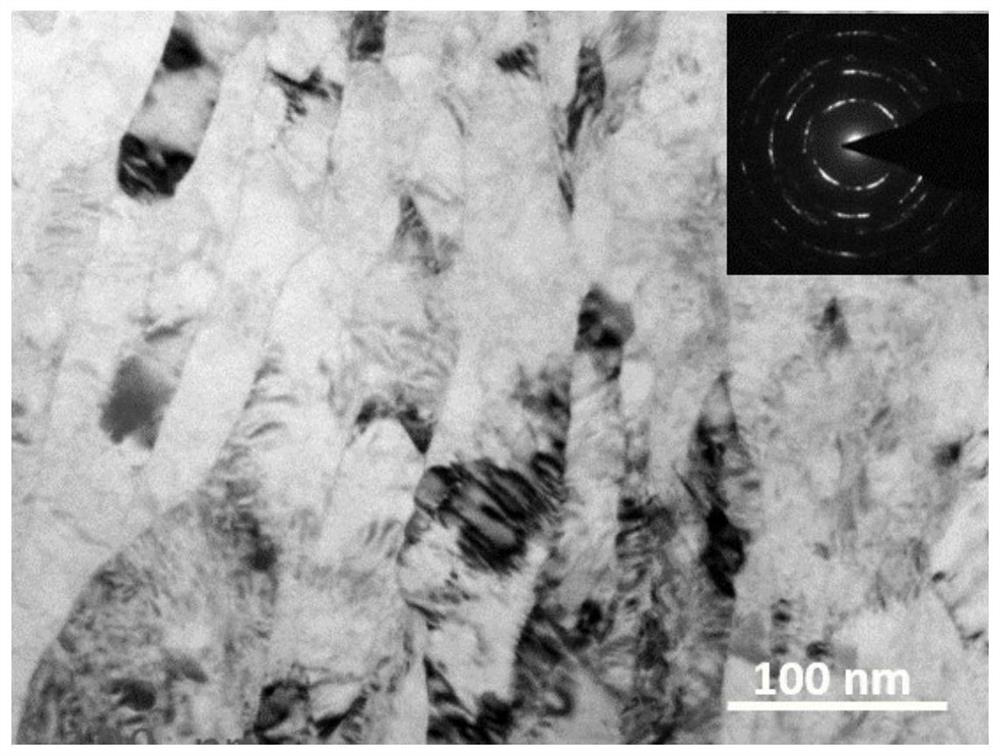

[0039] There are a large number of nanocrystals and a small amount of nano-twin structure in the nickel-based alloy obtained in this example. The sheets composed of nanocrystals, twins and matrix are full of dislocations and stacking faults. The average grain size of nanocrystals is ~ 39.0nm, the average thickness of the sheet composed of twins and the matr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com