Damp-proof pressure sensor

A pressure sensor and pressure technology, applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve the problems of reduced moisture-proof effect, device monitoring data error, and limited moisture-proof effect of pressure sensors, so as to reduce maintenance costs, reduce errors, and measure Precise effect of pressure value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

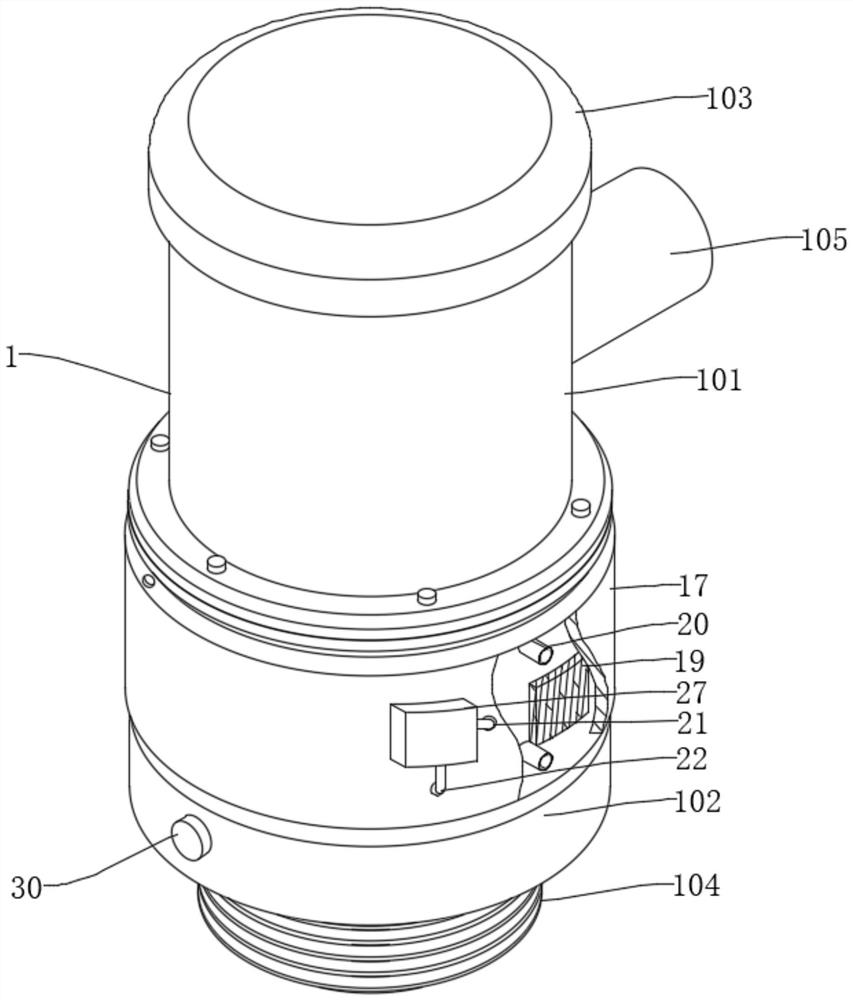

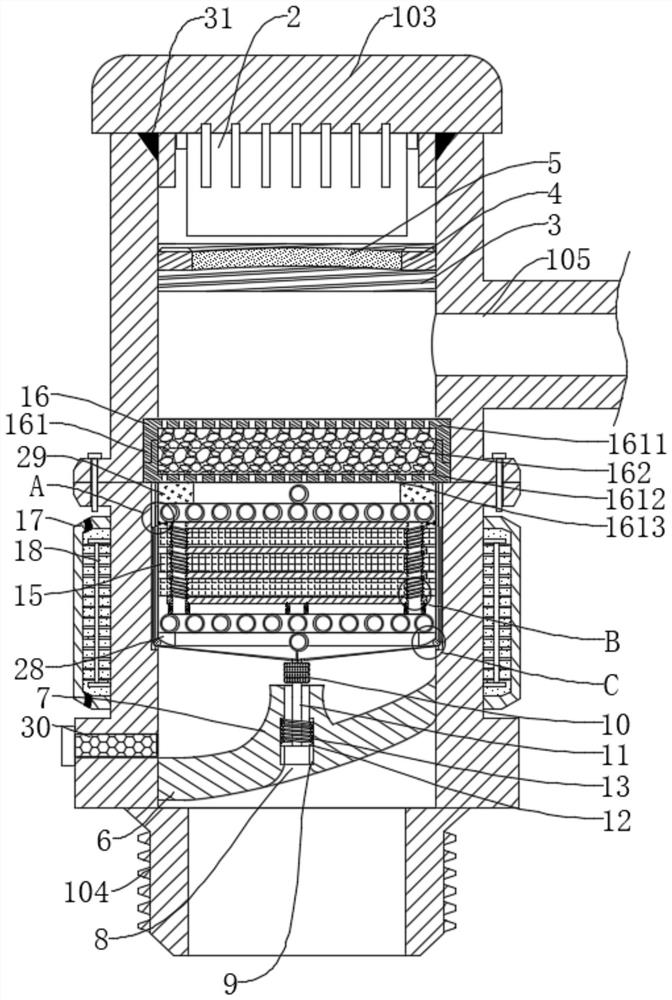

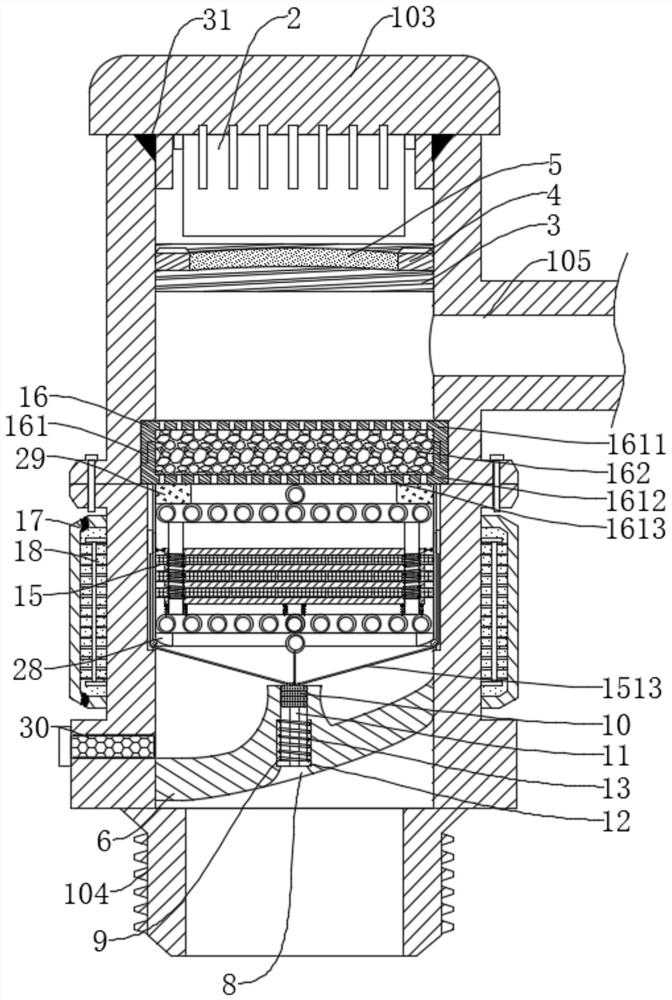

[0035] The present invention provides such Figure 1-11 A moisture-proof pressure sensor shown includes a casing 1, the casing 1 is composed of an upper casing 101, a lower casing 102 and a mounting cover 103, and the upper casing 101 is connected directly above the lower casing 102 through a sealed packing, so The installation cover 103 is threadedly connected to the top of the upper case 101, the bottom end of the lower case 102 is fixedly connected with a threaded joint 104, one side of the upper case 101 is provided with an exhaust port 105, the upper case 101, the lower case 102 , the threaded connection head 104 communicates with the exhaust port 105, the bottom end of the installation cover 103 is provided with a pressure probe 2, the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com