A method and equipment for wood carbonization treatment with atmospheric pressure superheated steam

A superheated steam and carbonization technology, applied in wood treatment, wood heat treatment, wood treatment details, etc., can solve the problems of slow carbonization, difficult wood carbonization, uneven carbonization, etc., to achieve fast carbonization speed, low steam pressure, and difficult The effect of spontaneous combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

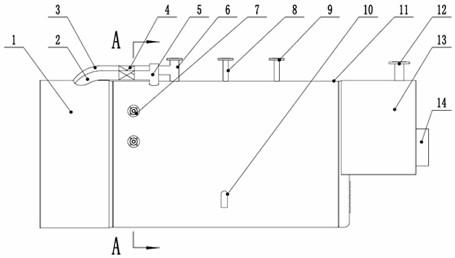

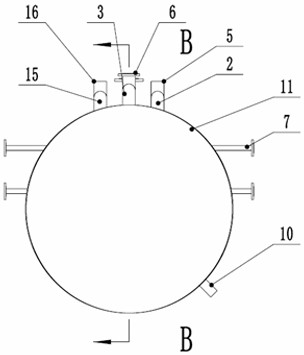

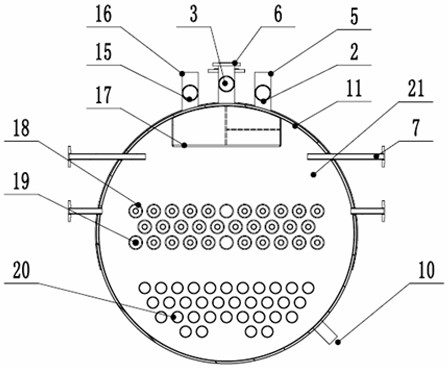

[0070] Atmospheric pressure superheated steam with a temperature greater than 230°C is used as the heat medium, and the superheated steam directly contacts the dry wood in the carbonization tank for heat exchange carbonization. The steps are as follows:

[0071] The first stage: Stack the wood with a moisture content of <25% after drying or natural drying in the carbonization tank, and close the airtight door of the carbonization tank; the wood is a plate or square material with a thickness of 25mm to 150mm after opening. Stacking requirements: the wood to be processed is stacked on the timber cart, the length and width of the timber pile are equal to the length and width of the timber cart, the height should be able to push the kiln door, and a square of 25×25mm should be used between the two layers of boards. Separated by spacers, heavy objects should be placed on the upper part of the pile or fixed with splints to avoid heat deformation.

[0072] The second stage: input sup...

Embodiment 2

[0086] Atmospheric pressure superheated steam with a temperature greater than 230°C is used as the heat medium, and the superheated steam directly contacts the dry wood in the carbonization tank for heat exchange carbonization. The steps are as follows:

[0087] The first stage: Stack the wood with a moisture content of <25% after drying or natural drying in the carbonization tank, and close the airtight door of the carbonization tank; the wood is a plate or square material with a thickness of 25mm to 150mm after opening. Stacking requirements: the wood to be processed is stacked on the timber cart, the length and width of the timber pile are equal to the length and width of the timber cart, the height should be able to push the kiln door, and a square of 25×25mm should be used between the two layers of boards. Separated by spacers, heavy objects should be placed on the upper part of the pile or fixed with splints to avoid heat deformation.

[0088] The second stage: Turn on t...

Embodiment 3

[0104] Atmospheric pressure superheated steam with a temperature greater than 230°C is used as the heat medium. The superheated steam directly contacts the wet wood in the carbonization tank for heat exchange and carbonization. The wet wood is wood that has not been dried or dried naturally. The steps are as follows:

[0105] The first stage: push and stack the wood into the tank, close the sealed door of the carbonization tank; the wood is a plate or square material with a thickness of 25mm to 150mm, and the stacking requirements of the wood: the wood to be processed is stacked on the material On the cart, the length and width of the wood pile are equal to the length and width of the wood cart, and the height should be able to push the kiln door. The two layers of boards should be separated by 25×25mm square spacers. Objects or fixed with splints to avoid thermal deformation.

[0106] The second stage: After loading the stacked wood in the carbonization tank, turn on the vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com