Microwave sintering method of ceramic coating

A ceramic coating and microwave sintering technology, which is applied in the field of microwave sintering of ceramic coatings and can solve problems such as insufficient concentration

Pending Publication Date: 2021-08-31

QINGDA SAISIDI NEW MATERIAL TECH BEIJING

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The content of fluorine, chlorine, bromine and other elements carried in urban waste fuel is very small in coal or natural gas fuel, especially the chlorine content in flue gas is dozens or even hundreds of times that of fossil fuels such as coal and natural gas. The CN104446325A formula contains Some components can effectively resist the corrosion of the above elements on the boiler, but it is still insufficient when the concentration is high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0015] Raw material preparation: preparing the CN104446325A 50Kg coating method; passivated aluminum powder 100g; ⑴10mm a thick steel plate 22mn; ⑵ waste incineration boiler waterwall.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

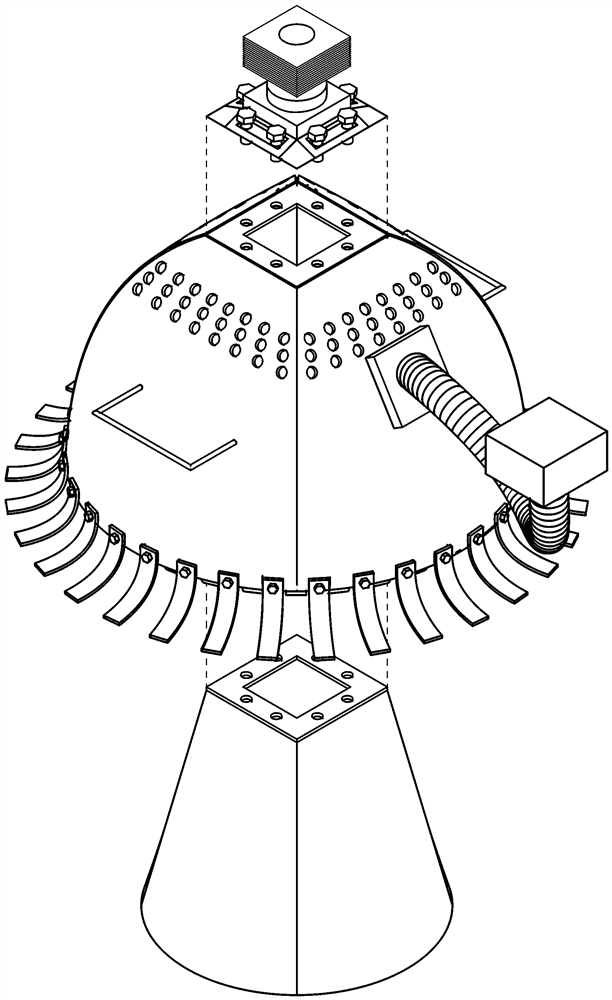

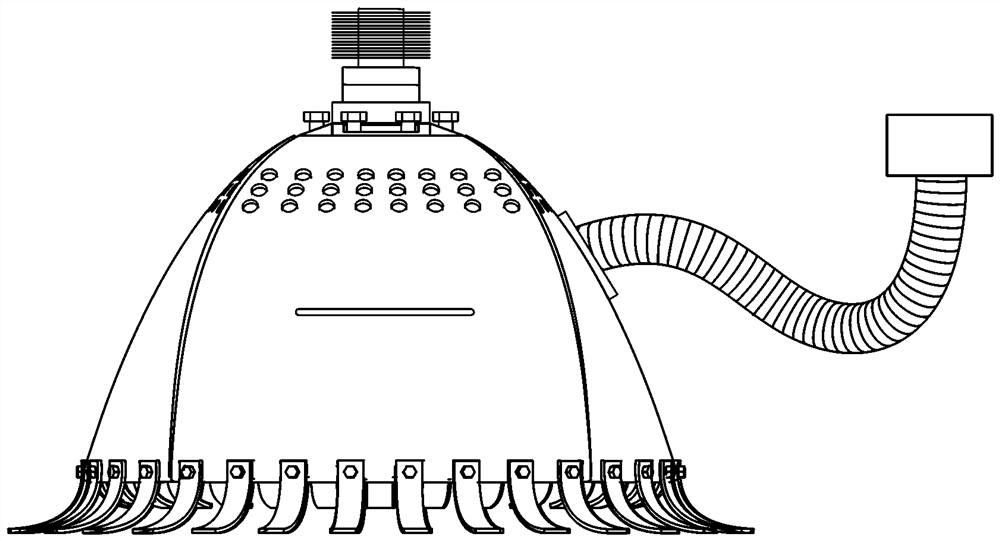

A ceramic coating mixed with an ignition agent is sprayed on parts such as a high-temperature superheater of a boiler, a water cooling wall and a furnace tube of a heating furnace, and is scanned and sintered by a portable microwave sintering device after being dried. The microwave scanning sintering has the characteristics of easy temperature control, stability and good sintering surface consistency. The microwave-sintered ceramic coating can give full play to the characteristics of corrosion resistance, contamination resistance and slagging resistance of the ceramic coating. The ceramic coating is especially suitable for urban waste incineration boilers. The portable microwave sintering device is composed of a magnetron, a connecting flange, a shielding shell, a smoke exhaust pipeline, a fan, a microwave trap filter and a waveguide. Manual or robot scanning operation is adopted, and safety and high efficiency are achieved.

Description

Technical field [0001] It is a special paint industry, microwave sintering technology. Background technique [0002] The ceramic coating is applied to a boiler superheater, water wall tubes and other parts of the furnace, corrosion-resistant, anti-staining, anti-slagging, increase the heat transfer, reduces boiler maintenance and many other benefits. Currently, the industry has been widely accepted and widely used. [0003] Chinese Patent CN104446325A discloses a high temperature resistant, anti-staining, anti-slagging ceramic coating, its preparation method and application method. Prepared in accordance with the technical solution ceramic coatings it has been widely used in coal-fired boilers, especially in power generation boilers and boiler to be fully recognized by the user. [0004] With the popularity of the application, in addition to other coal-fired boilers have begun to use this technology. Since the fuel difference, shape difference furnace, as a result of different te...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B35/64C04B35/622

CPCC04B35/64C04B35/62222C04B2235/667

Inventor 孙荣祥龚浩然王聪

Owner QINGDA SAISIDI NEW MATERIAL TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com