Preparation method of temperature-sensitive hydrogel

A temperature-sensitive hydrogel and photoinitiator technology, which is applied in the field of polymer materials, can solve the problems of limited development prospects and low mechanical strength of PNIPPAM hydrogels, and achieves simple and efficient preparation process, excellent mechanical strength, and good biocompatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

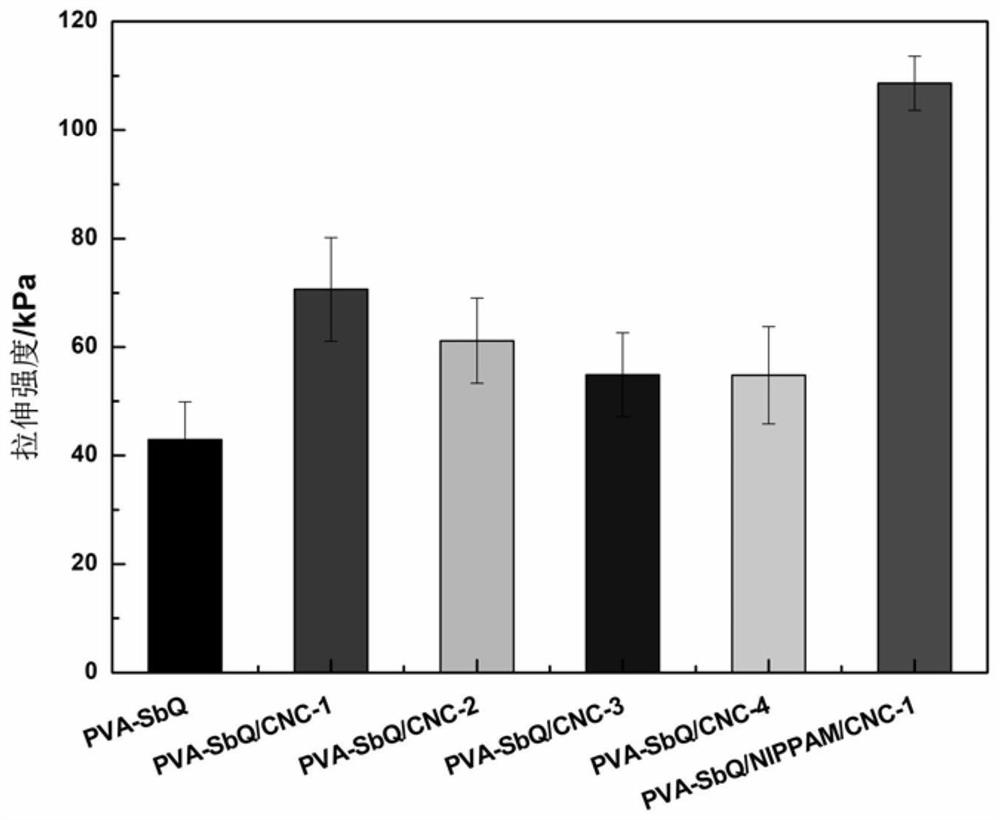

[0031] Take 10g 8% PVA-SbQ solution, add 0.23g 3.45% CNC suspension, 0.3g NIPPAM and 0.009g photoinitiator to it, stir for 1 hour, let it stand for 0.5 hour, after the bubbles are completely eliminated, pour it into the local In a surface glass with different light transmittance (for example, the words "Material Youth" are written on a conventional surface glass through a dark pigment), put 40W / cm 2 Irradiated under ultraviolet light for 6 minutes to obtain PVA-SbQ / NIPPAM / CNC thermosensitive hydrogel, denoted as PVA-SbQ / NIPPAM / CNC-1, the tensile strength test results can be found in figure 1 .

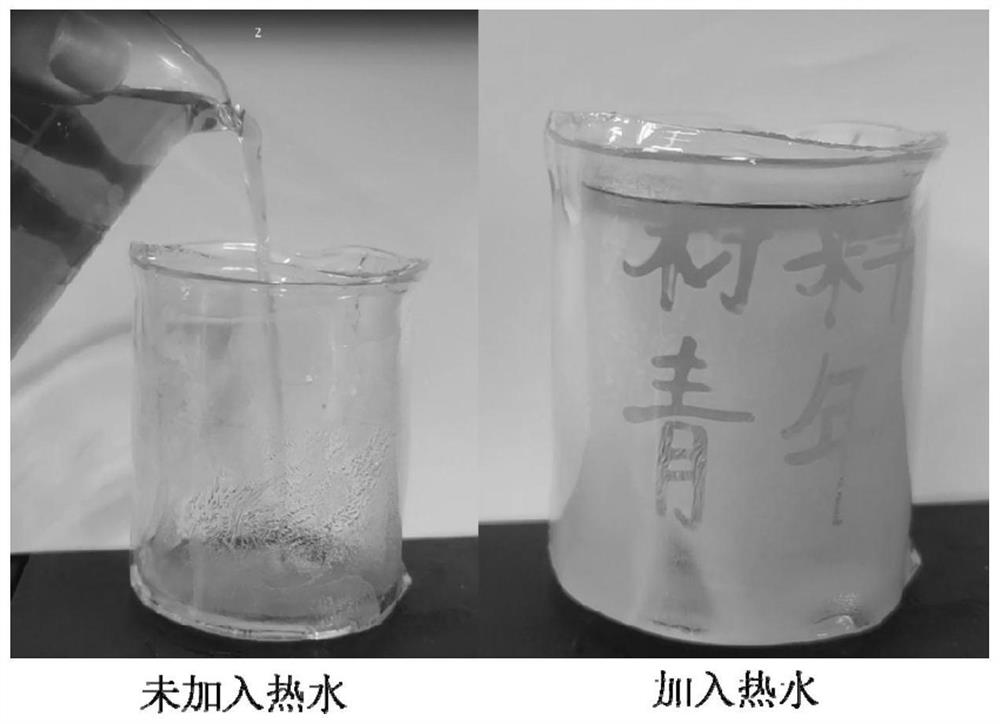

[0032] Through the temperature sensitivity test, the temperature sensitivity test result figure of the PVA-SbQ / NIPPAM / CNC composite hydrogel prepared in Example 1 of the present invention can be found in figure 2 . Before adding hot water, the surface of the beaker with the temperature-sensitive hydrogel was colorless and transparent; after adding hot water, the surface of the beake...

Embodiment 2

[0034] Take 10g 8% PVA-SbQ solution, add 0.46g 3.45% CNC suspension, 0.3g NIPPAM and 0.009g photoinitiator to it, stir for 1 hour, let it stand for 0.5 hour, after the bubbles are completely eliminated, pour it into the local In the watch glass with different light transmittance, put it at 40W / cm 2After irradiating with ultraviolet light for 6 minutes, the PVA-SbQ / NIPPAM / CNC thermosensitive hydrogel was obtained, which was denoted as PVA-SbQ / NIPPAM / CNC-2.

Embodiment 3

[0036] Take 10g 8% PVA-SbQ solution, add 0.69g 3.45% CNC suspension, 0.3g NIPPAM and 0.009g photoinitiator to it, stir for 1 hour, let it stand for 0.5 hour, after the bubbles are completely eliminated, pour it into the local In the watch glass with different light transmittance, put it at 40W / cm 2 After irradiating under ultraviolet light for 6 minutes, the PVA-SbQ / NIPPAM / CNC thermosensitive hydrogel was obtained, which was denoted as PVA-SbQ / NIPPAM / CNC-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com