Special mold silica gel for simulated ancient building mold-rollover and preparation method of mold silica gel

An ancient building and silica gel technology, which is applied in the field of special mold silica gel for simulating ancient building molds and its preparation, can solve the problems of insufficient hardness, inability to balance hardness and mechanical strength, and insufficient mechanical strength, so as to increase hardness and increase flow. performance and mechanical properties, and the effect of increasing the number of overturning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Component A includes: 80 parts of base rubber, 30 parts of vinyl silicone oil, 5 parts of MQ resin, 0.2 parts of castor catalyst; component B includes: 5 parts of hydrogen-containing silicone oil, 0.5 parts of inhibitor.

[0029] Wherein, the base rubber material is prepared by mixing alkoxy vinyl silicone oil, reinforcing filler and silazane treatment agent.

[0030] Further, in the base rubber material, there are 5 parts of alkoxy vinyl silicone oil, 25 parts of reinforcing filler, and 5 parts of silazane treatment agent.

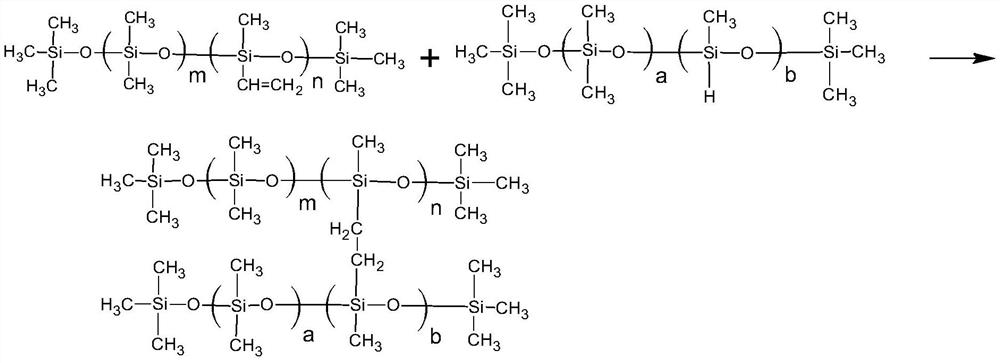

[0031] Among them, the alkoxy vinyl silicone oil is a silicone oil with alkoxy groups at both ends and vinyl side chains, and its structural formula is

[0032] In the formula, m=50, n=3.

[0033] Further, the alkoxy vinyl silicone oil is prepared by mixing silicone oil with hydroxyl groups at both ends of vinyl groups on side chains and ethanol, and the mass ratio of silicone oil with hydroxyl groups at both ends of vinyl groups at side chains ...

Embodiment 2

[0046] The difference between this embodiment and embodiment 1 is:

[0047] Component A includes: 90 parts of base rubber, 45 parts of vinyl silicone oil, 15 parts of MQ resin, 0.3 parts of castor catalyst; component B includes: 6 parts of hydrogen-containing silicone oil, 0.7 parts of inhibitor.

[0048] Wherein, the mass ratio of the fumed silica and the vinyl MQ resin is 4:1.

[0049] Wherein, the gas-phase surface area of the fumed silica is 350g / m 2 .

[0050] Among them, the viscosity of hydrogen-containing silicone oil is 50CS, and the hydrogen content is 0.30%.

[0051] Wherein, the mass ratio of alkoxy vinyl silicone oil to fumed silica is 1:4.

[0052] Wherein, the structural formula of alkoxy vinyl silicone oil is

[0053] In the formula, m=100, n=5.

[0054] The difference between the preparation method of this example and Example 1 is as follows: in step (1), after adding the raw materials into the reactor, react at 70°C for 6 hours, and then raise the te...

Embodiment 3

[0056] The difference between this embodiment and embodiment 1 is:

[0057] Component A includes: 100 parts of base rubber, 50 parts of vinyl silicone oil, 20 parts of MQ resin, 0.4 parts of castor catalyst; component B includes: 8 parts of hydrogen-containing silicone oil, 0.8 parts of inhibitor.

[0058] Wherein, the mass ratio of the fumed silica and the vinyl MQ resin is 5:1.

[0059] Wherein, the gas-phase surface area of the fumed silica is 300g / m 2 .

[0060] Among them, the viscosity of hydrogen-containing silicone oil is 30CS, and the hydrogen content is 0.40%.

[0061] Wherein, the mass ratio of alkoxy vinyl silicone oil to fumed silica is 1:6.

[0062] Wherein, the structural formula of alkoxy vinyl silicone oil is

[0063] In the formula, m=200, n=5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com