Method for processing graphene plate

A graphene and working technology, which is applied in the field of graphene plate processing, can solve the problems of inability to stabilize and protect the graphene plate, and achieve the effect of increasing the convenience and stability of use, preventing position deviation, and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

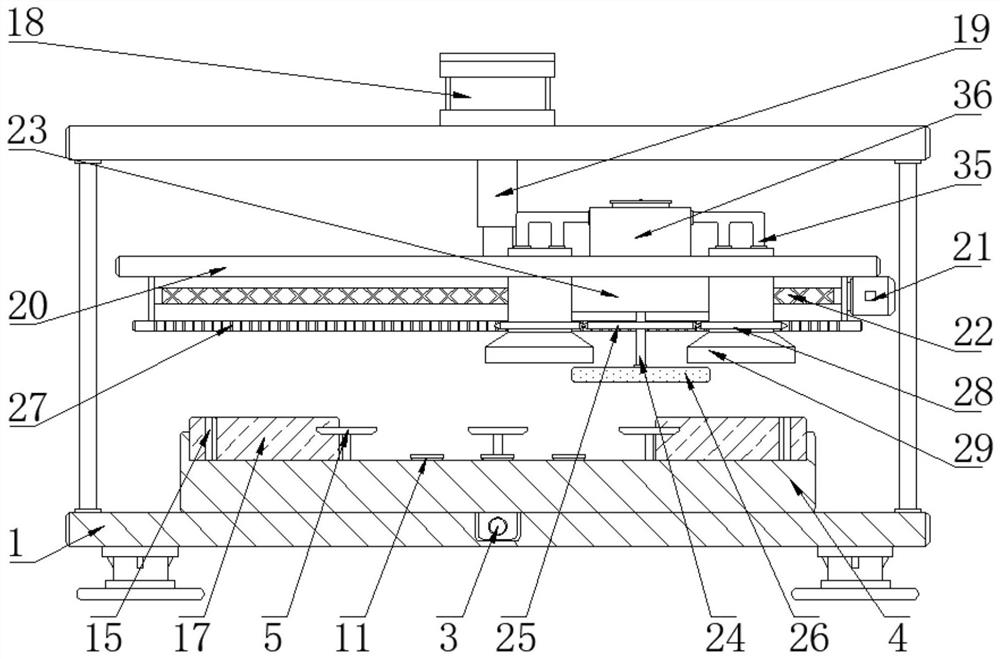

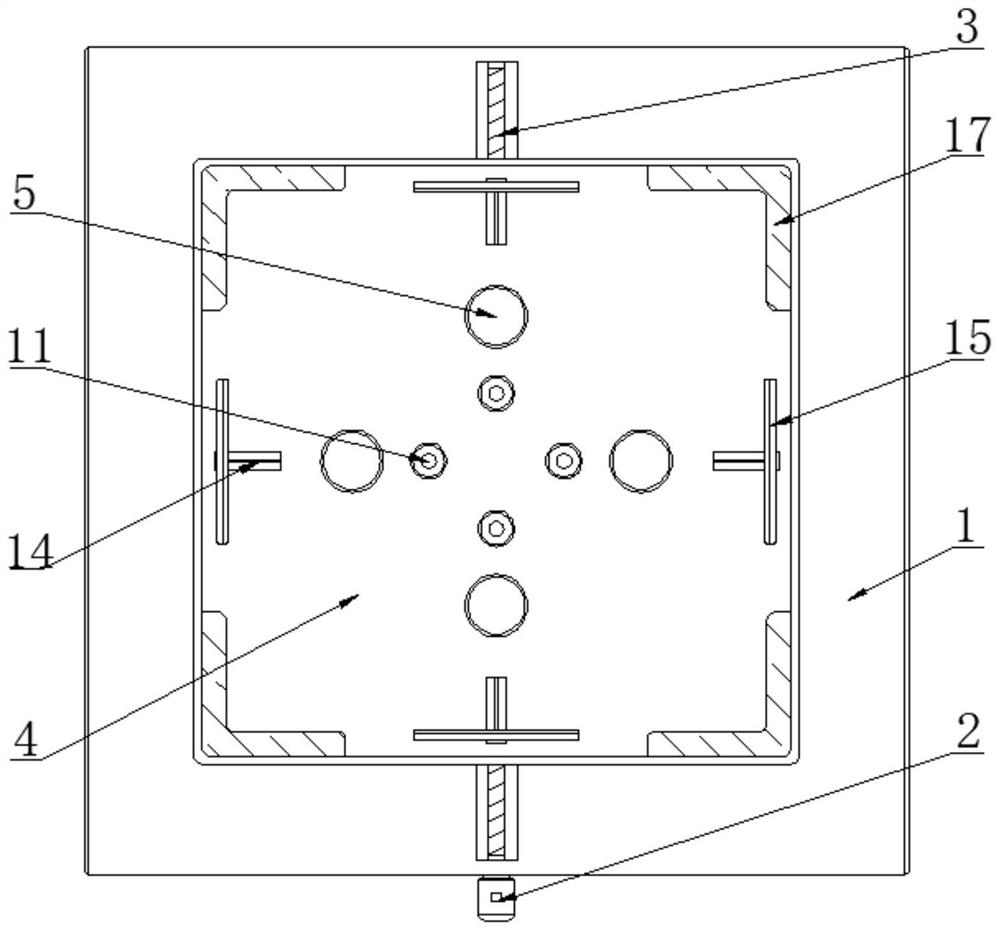

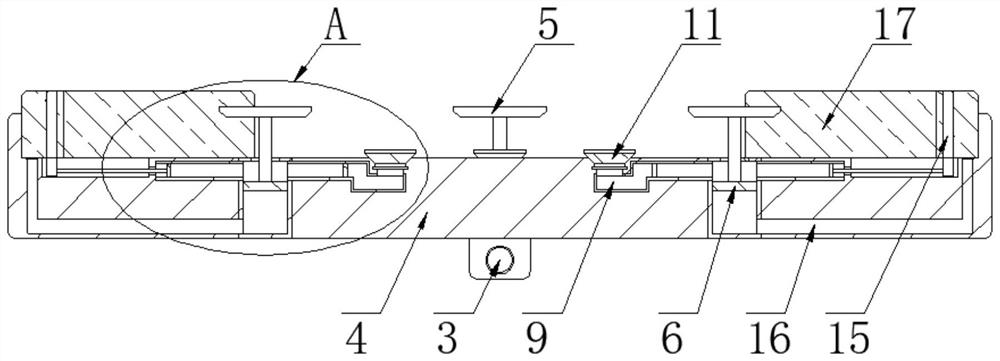

[0038] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0039] At present, when the existing grinding device is grinding the graphene plate, it is necessary to use a clamp to clamp and fix the graphene plate. However, the conventional clamp cannot precisely control the clamping force. While holding and fixing, the graphene plate cannot be stably protected, and then the clamping stability and safety of the graphene plate cannot be guaranteed.

[0040] And because the graphene plate will produce a large amount of powder in the grinding process, and the conventional grinding device cannot automatically recycle the powder during the grinding process, the practicability is poor, so the inventor proposed a processing graphene plate method to solve the above problems.

[0041]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com