A treatment process for degreasing wastewater

A wastewater treatment and process technology, applied in the field of degreasing wastewater treatment process, can solve the problems of difficult operation, large consumption of chemicals, poor operation stability, etc., and achieve the effect of reducing human workload, high degree of automation, and reducing water volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

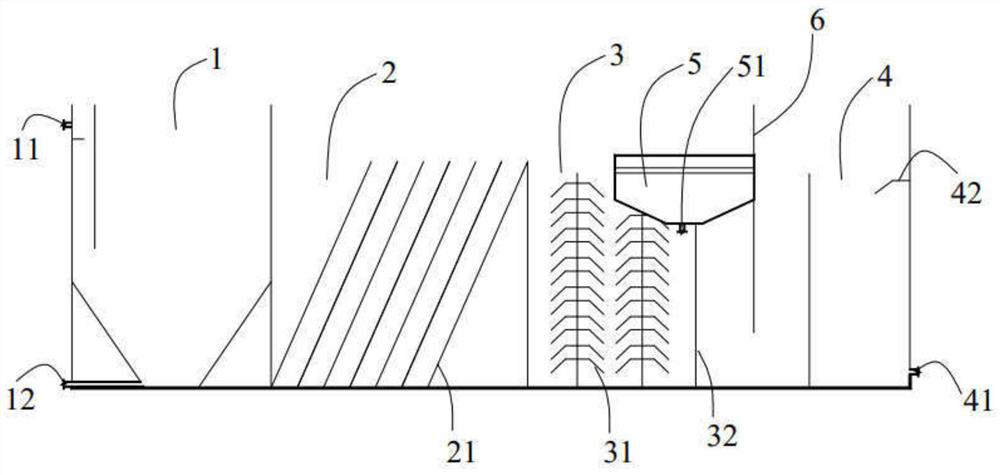

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

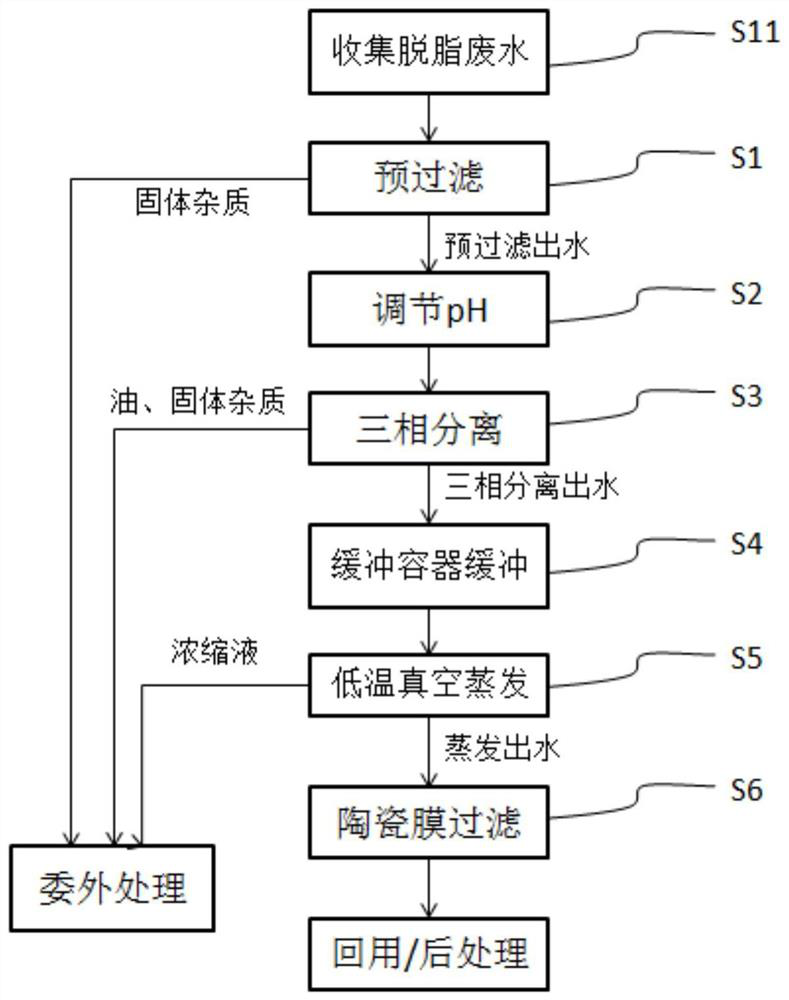

[0031] See figure 1 A kind of degreasing wastewater treatment process shown, it comprises the steps:

[0032] S1: pre-filtering the degreasing wastewater to remove some solids and oil in the degreasing wastewater to obtain pre-filtered water;

[0033] S2: adjusting the pH value of the pre-filtered water to 8.5-9;

[0034] S3: performing three-phase separation on the adjusted pre-filtered water to remove solids and oil in the pre-filtered water to obtain three-phase separated water;

[0035] S4: Collect the three-phase separated water and control the three-phase separated water to be within a preset liquid level range.

[0036] S5: Separating the water from the three phases for low-temperature vacuum evaporation treatment to obtain evaporated wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com