Epoxy chloropropane production process and device thereof

A technology of epichlorohydrin and production process, which is applied in the chemical industry, sustainable manufacturing/processing, fixed tubular catheter components, etc., and can solve problems such as recycling and environmental protection that are difficult to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

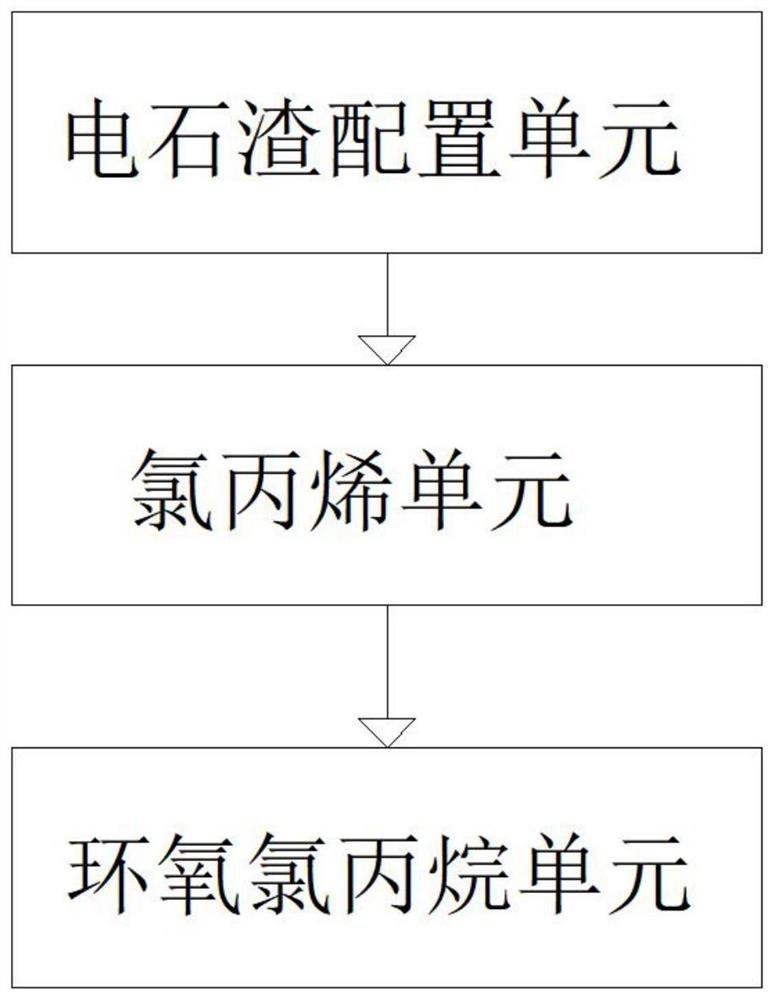

[0048] like figure 1 As shown, the present embodiment provides a kind of epichlorohydrin production process, and it comprises the following steps:

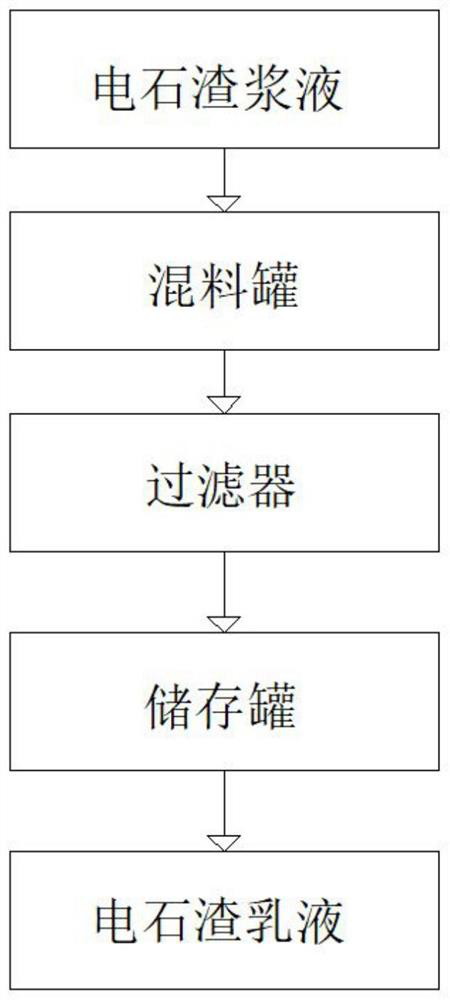

[0049] Step 1. Calcium carbide slag configuration

[0050] In this step, it is used to obtain calcium carbide slag emulsion containing about 20% calcium hydroxide;

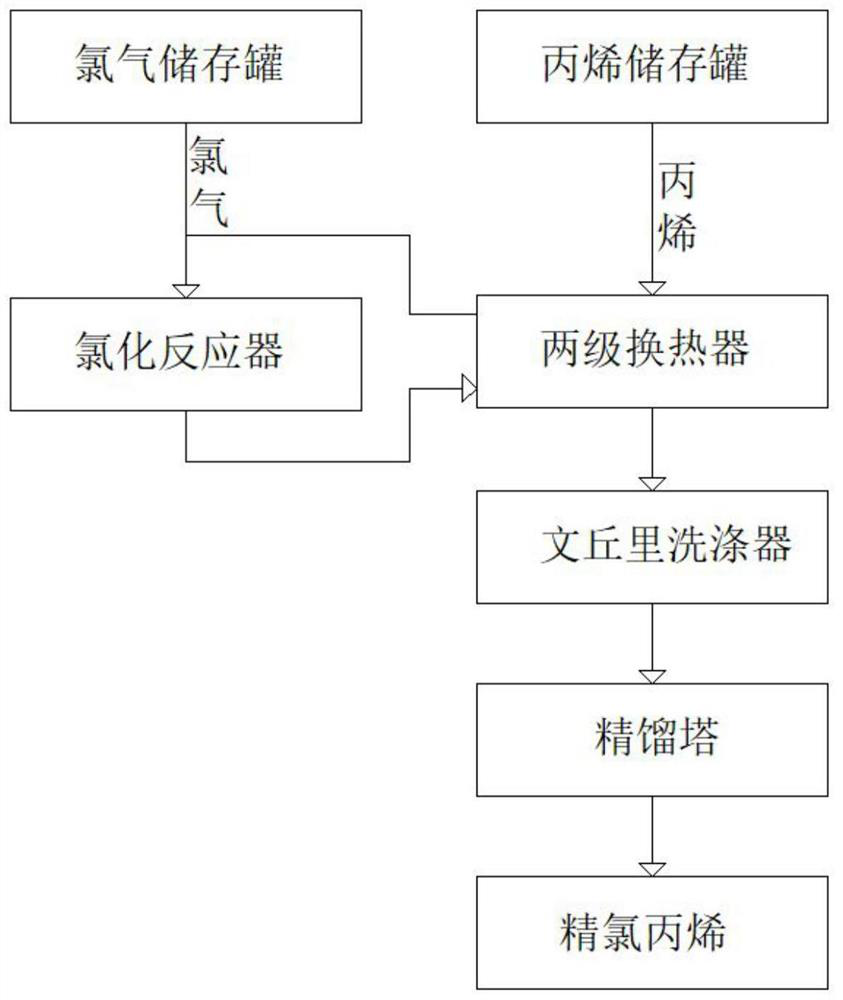

[0051] Step 2, preparation of allyl chloride

[0052] In this step, it is used to obtain allyl chloride;

[0053] Step 3, preparation of epichlorohydrin

[0054] In this step, epichlorohydrin is prepared from the calcium carbide slag emulsion obtained in step 1 and the chloropropene obtained in step 2.

[0055] In this embodiment, the preparation of epichlorohydrin can be preferably realized through steps one to three.

[0056] Meanwhile, in order to realize the method in this embodiment, this embodiment also provides an epichlorohydrin production device, which includes a carbide slag configuration unit, a chloropropene unit, and an epichlorohydrin unit, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com