Application of natural gas as hydrogen flame retardant and fuel suitable for hydrogen-oxygen burner

A natural gas and flame retardant technology, applied in the field of combustion, can solve the problems of wide flammable limit of hydrogen, weakened cutting ability, shortened cutting and welding flame secant line, etc., to achieve the optimal balance of safety and combustion performance, and reduce the combustion speed. , the effect of reducing the flammable limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

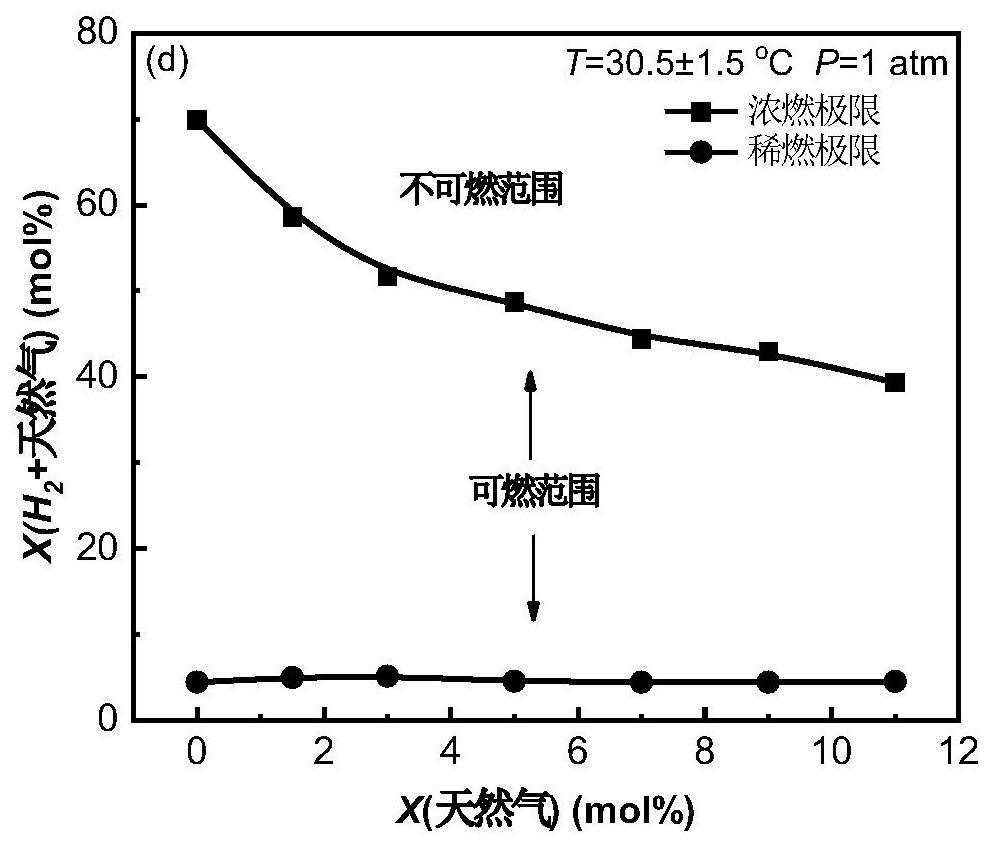

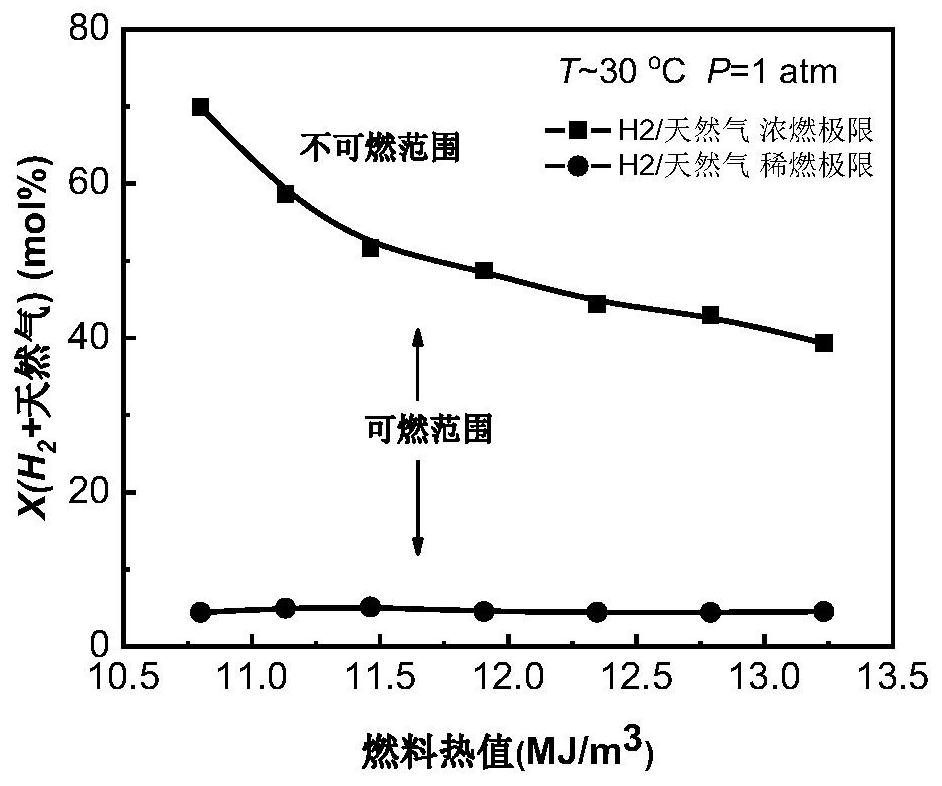

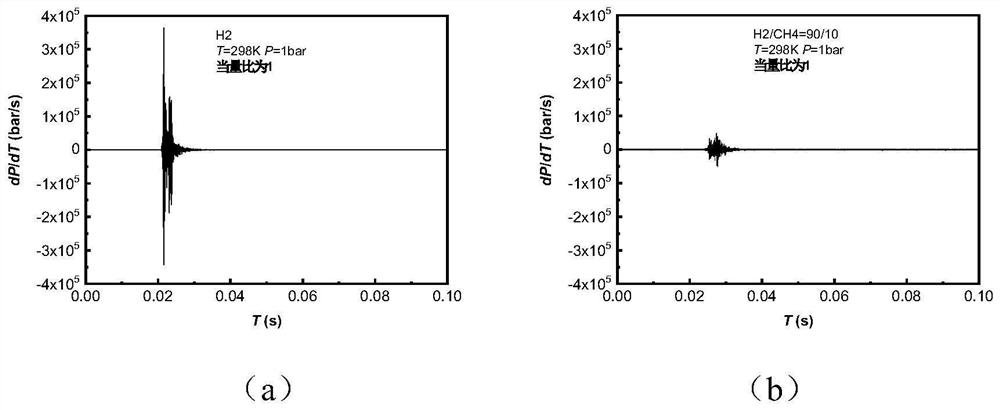

[0015] In the present invention, natural gas is premixed into hydrogen fuel as a flame retardant, and the optimal blending ratio range of natural gas blending is ensured that the combustion speed of the mixed gas is not much lower than that of pure hydrogen, and the combustion calorific value does not change much. 2%-5.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com