A dry dust removal evaporative cooler, dust removal system and dust removal process

An evaporative cooler and dry dust removal technology, which is applied in metal processing, manufacturing converters, sustainable manufacturing/processing, etc., can solve problems such as excessive flue gas humidity, wall scaling, and uneven spraying of nozzles, etc., to achieve Improve the degree of automation, reduce condensation, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

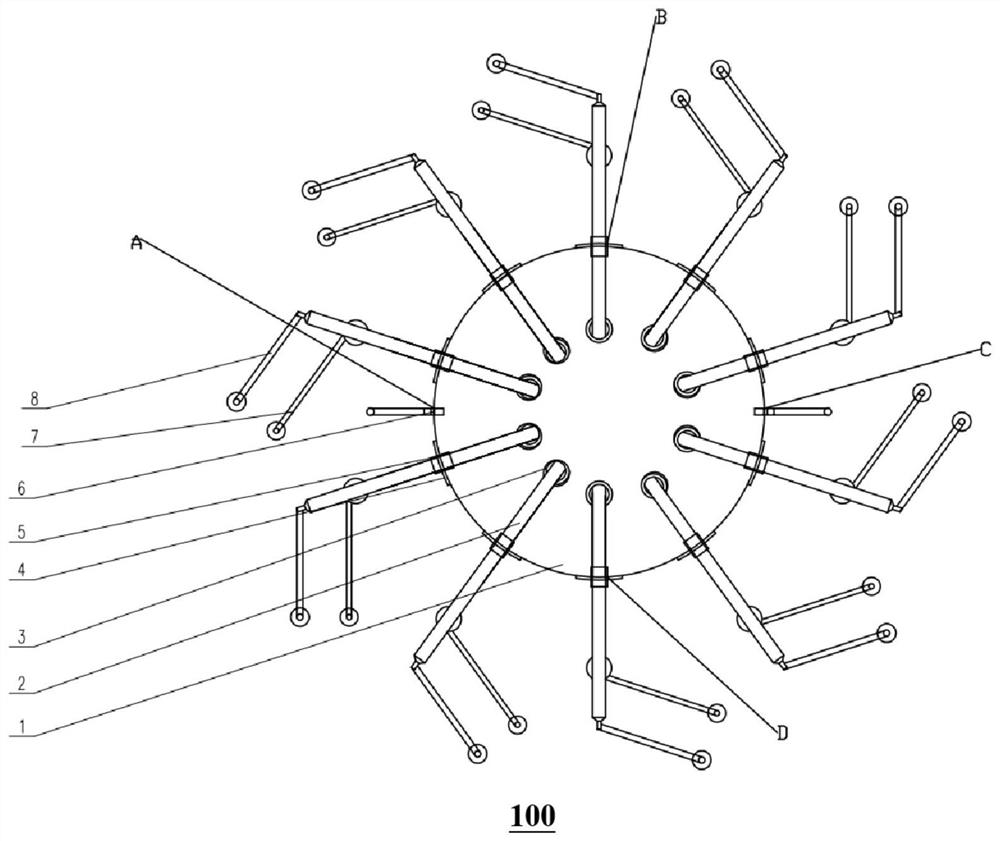

[0043] The embodiment of the present application provides a dry dedusting evaporative cooler 100, which can be applied to the LT dry dedusting transformed from the OG method through the improvement of the structure of the evaporative cooler 100 and the improvement of the arrangement of the spray guns 2 in it. system.

[0044] combine figure 1 shown.

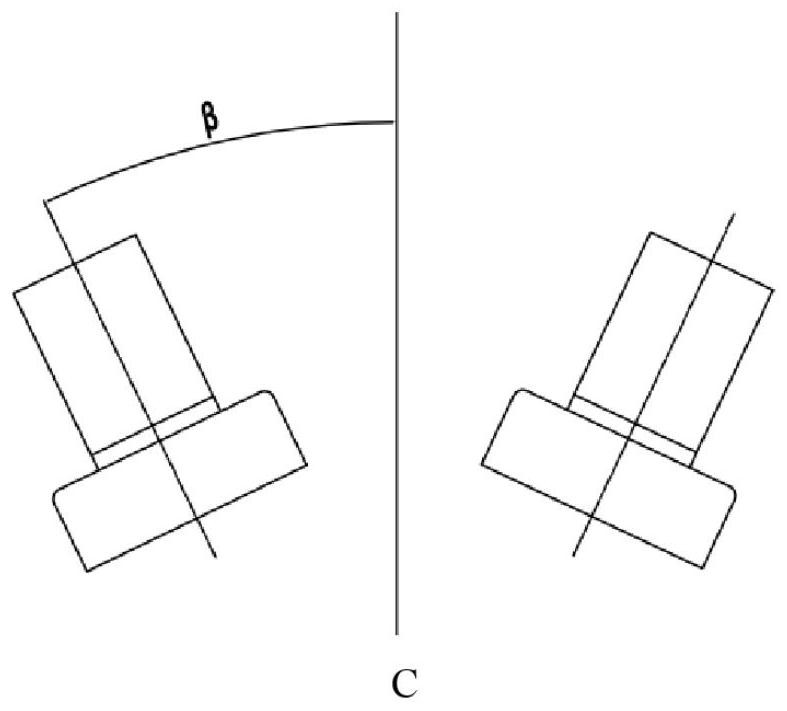

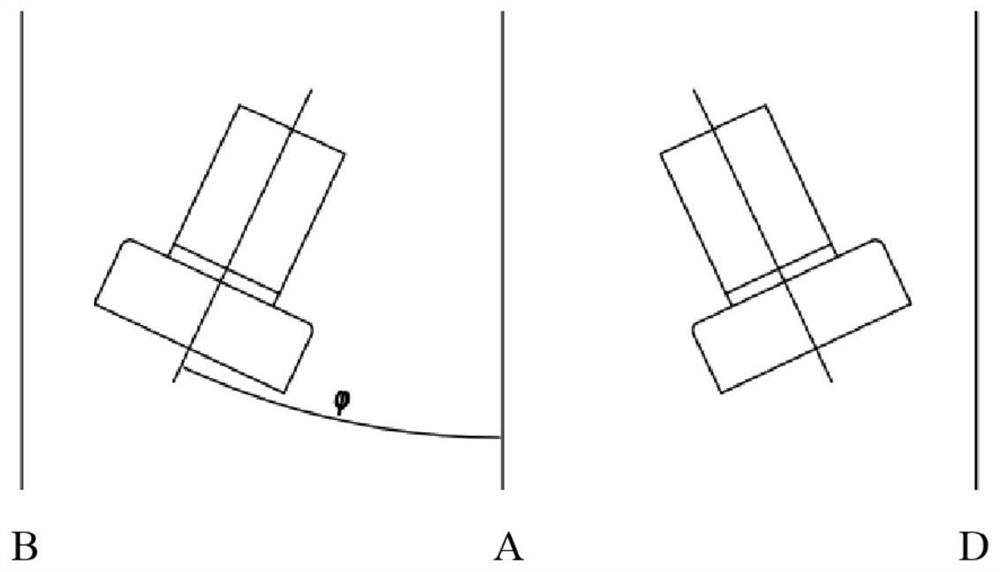

[0045] The evaporative cooler 100 includes a spray gun 2 arranged around the evaporative cooler body 1, one end of the spray gun head 3 of the spray gun 2 extends into the evaporative cooler body 1, and the other end of the spray gun 2 is connected to the spray gun air supply pipe 7 and the spray gun water supply pipe 8, The spray gun 2 realizes the adjustment of the length of the spray gun 2 extending into the evaporative cooler body 1 and the angle of the spray gun 2 through the spray gun fixing flange 4 and the spray gun adjustment sleeve 5 fixed on the evaporative cooler body 1 . The evaporative cooler body 1 is divided int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com