Single-pole double-throw coplanar waveguide type radio frequency mechanical switch structure

A coplanar waveguide, single-pole double-throw technology, applied in the direction of waveguide-type devices, electrical components, circuits, etc., can solve the problem of miniaturization, integration indicators cannot form a qualitative breakthrough, and the size of the switch body cannot be miniaturized and improved. requirements and other issues, to achieve the effects of miniaturization, size reduction, and low insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

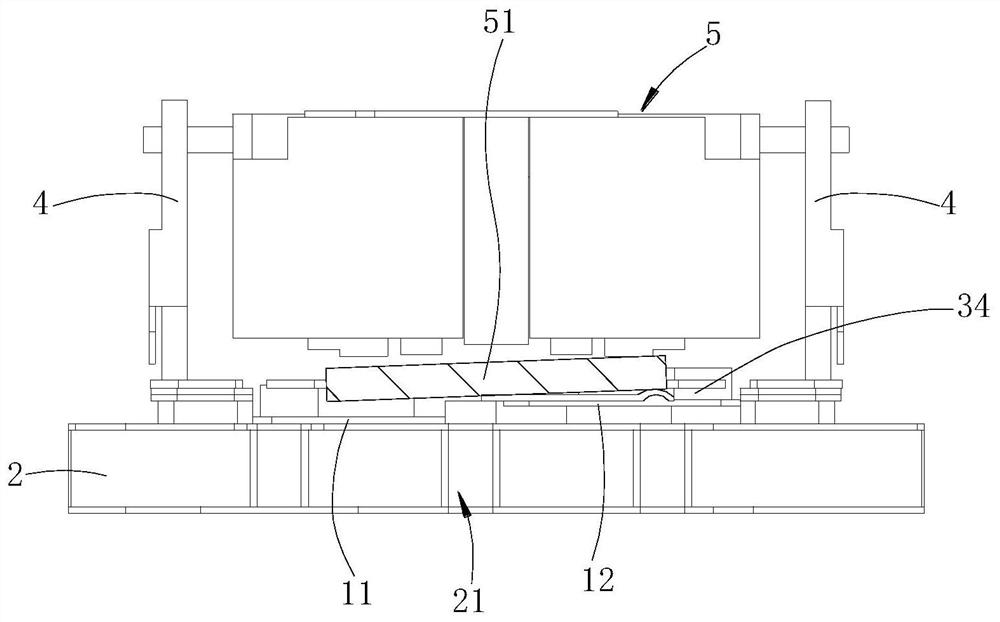

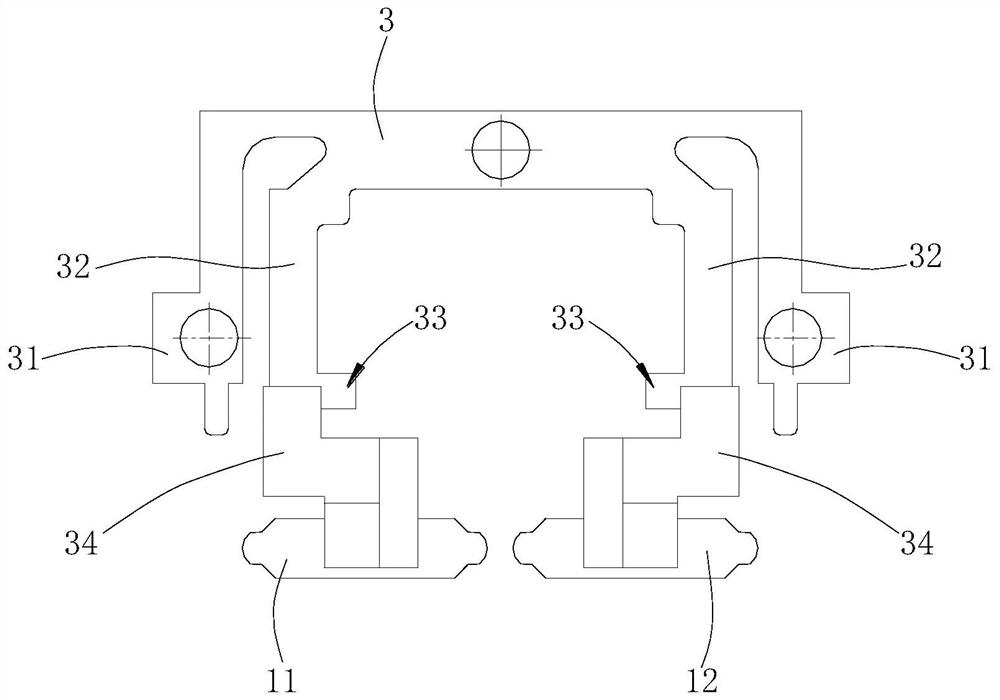

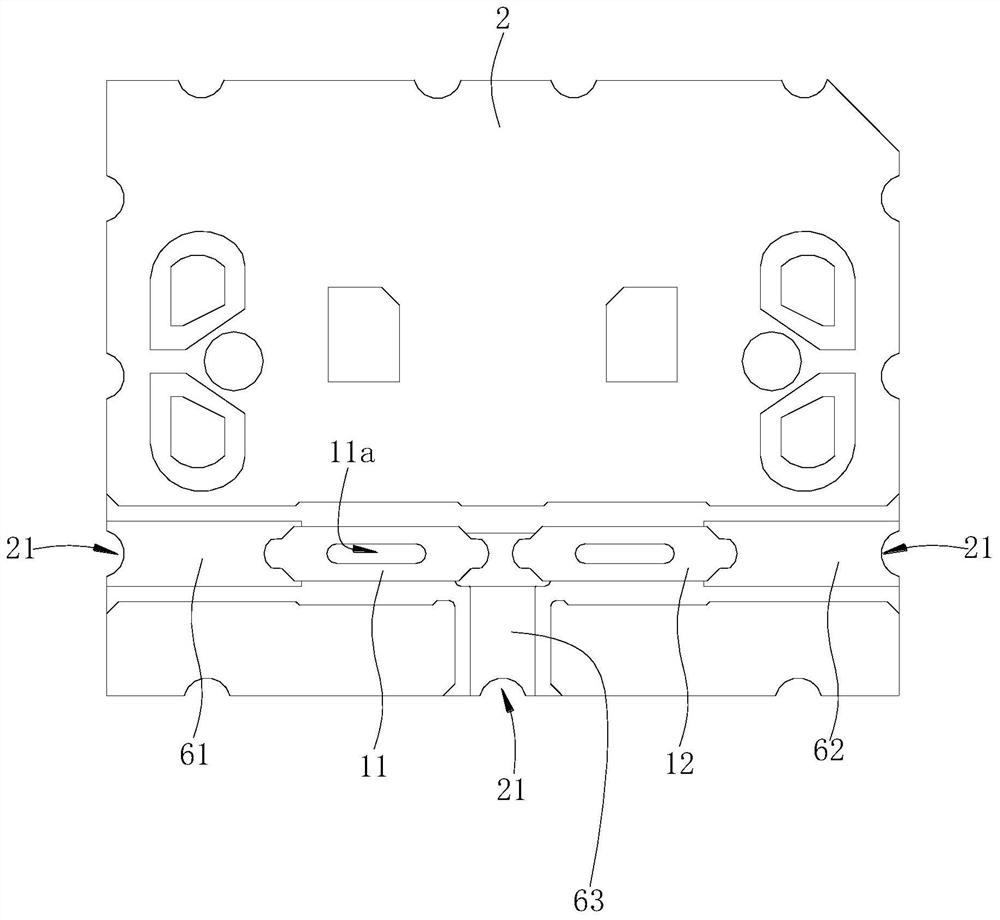

[0025] Such as Figures 1 to 3 shown.

[0026] The switch structure includes a radio frequency substrate 2, a transmission reed 3, two radio frequency reeds and three microstrip pieces.

[0027] The two RF reeds are hard gold plated on the surface of beryllium copper material, the two RF reeds are respectively the first RF reed 11, the second RF reed 12, the structure of the first RF reed 11 and the second RF reed 12 Similarly, taking the first radio frequency reed 11 as an example, the first radio frequency reed 11 includes a horizontal plate body and a vertical portion, the upper end of the horizontal plate body has an assembly groove 11a, and the assembly groove 11a extends into the vertical portion.

[0028] The RF substrate 2 adopts Rogers 4003 board, which is coated with copper on both sides and then gold-plated. Three microstrips are respectively welded on the RF substrate 2. The three microstrips are independent of each other. The three microstrips are J1 microstrips ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com