Macroelement water-soluble fertilizer particle production device

A production device, a technology of a large number of elements, applied in the direction of granulation in rotating tanks, extrusion granulation of raw materials, fertilizer mixture, etc., can solve the problems of environmental pollution, damage to application equipment, low utilization rate of plants, etc. Ensure uniformity and avoid the effect of eccentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, in the following descriptions, specific system structures, technologies, etc. are proposed for the purpose of illustration rather than limitation. The specific details for a thorough understanding of the embodiments of the present invention. It will be apparent, however, to one skilled in the art that the invention may be practiced in other embodiments without these specific details. In other instances, detailed descriptions of well-known systems, devices, circuits, and methods are omitted so as not to obscure the description of the present invention with unnecessary detail.

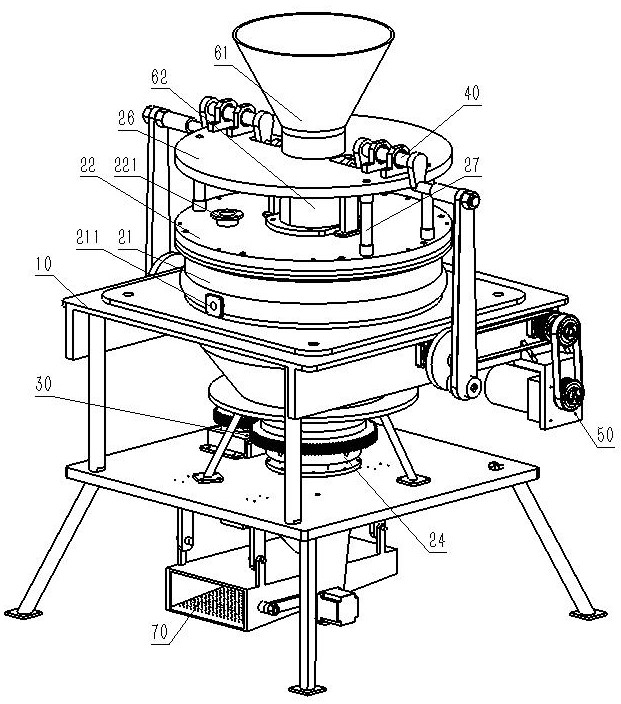

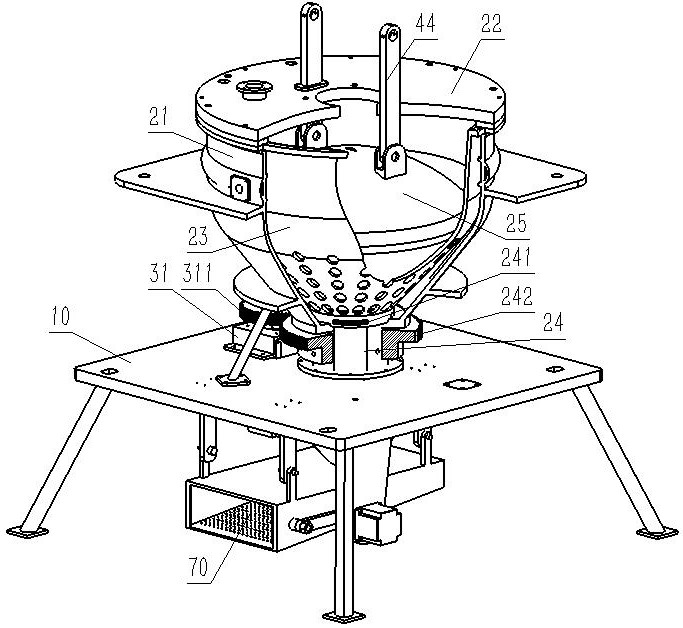

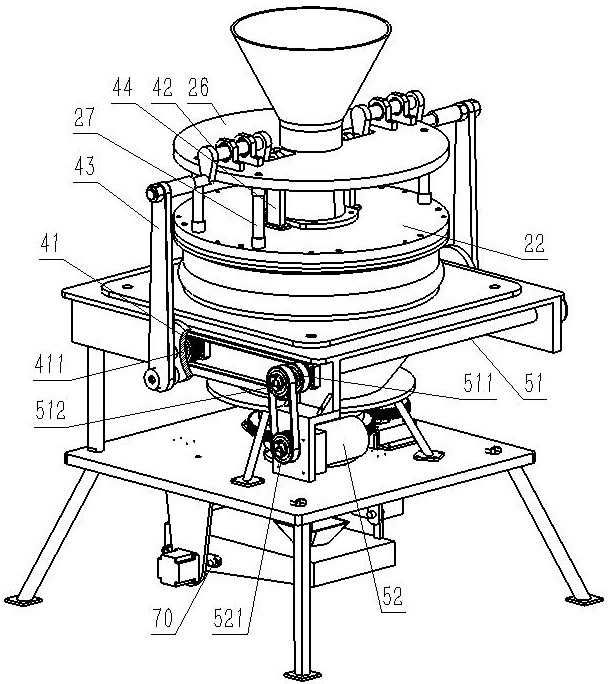

[0041] The invention provides a production device for water-soluble fertilizer granules with a large number of elements. figure 1 To attach Figure 4 It can be seen that a large amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com