Method of applying two-frequency electromagnetic field to improve quality of continuous casting

A continuous casting billet and electromagnetic field technology, which is applied in the field of metal material processing, can solve the problems of mold slag entrainment and nozzle erosion, blocked mold slag channels, and deteriorated lubrication effect, so as to improve the initial solidification process and reduce the occurrence of surface cracks. The effect of improving the probability and liquid level stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

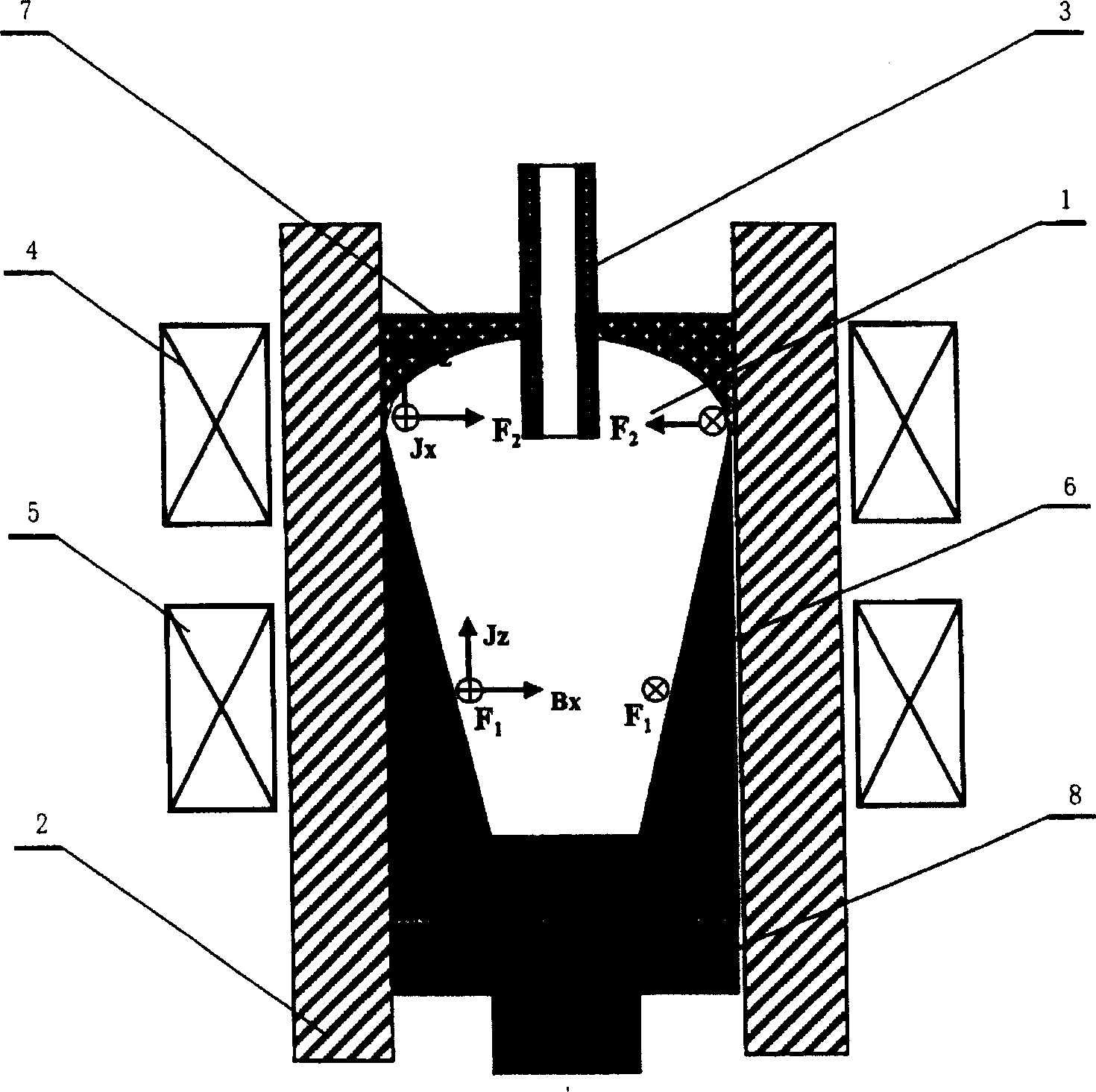

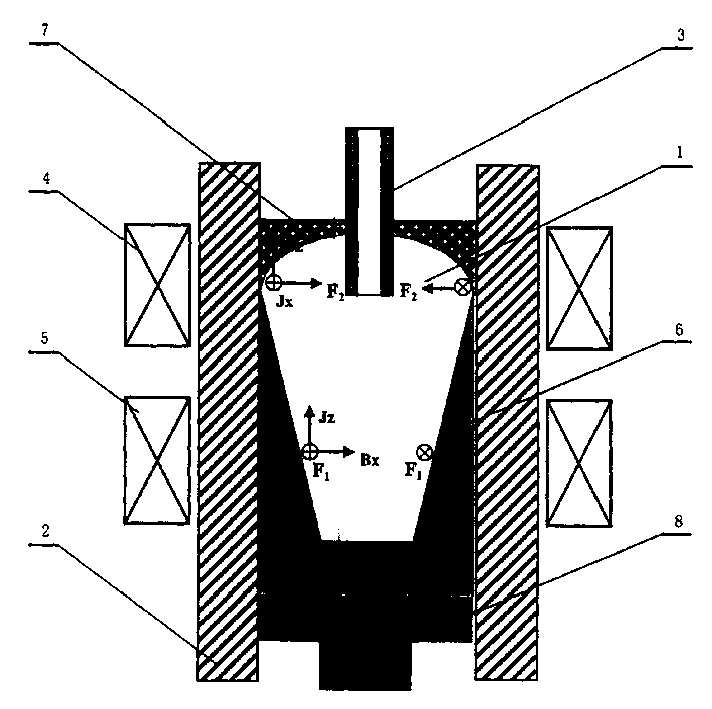

[0016] A certain unit produces billets with a cross-section of 100×100mm. The material is high-quality carbon steel with a carbon content of 0.18%. The surface roughness of the slab is required to be less than 0.2. Less than 0.8 pieces / 100cm 2 , used for rolling wire. In the production process, the technical parameters selected by the present invention are: adopt copper electromagnetic crystallizer 2, its internal size is 100×100×400mm, and its external size is 146×146×400mm, along 4 sides at 20mm from the upper end surface of the crystallizer 20 equally spaced slots with a width of 0.4mm and a length of 280mm are opened longitudinally; a high-frequency coil 4 is set at a distance of 50mm from the top of the crystallizer 2, the number of turns is 5 turns, the internal size is 150×150×70mm, and the external size 174×174×70mm, high-frequency power supply frequency is 40kHZ; applied power is 45kw. The maximum value of the magnetic induction Bz in the crystallizer is 330G; a low...

Embodiment 2

[0018] A certain unit produces round slabs with a section of φ100mm, the material is low alloy steel, the surface roughness of the slab is required to be less than 0.25, the ratio of equiaxed grains in the slab is greater than 70%, and the number of inclusions is less than 1 / 100cm 2 , used as rolled pipe. In the production process, the selected technical parameters of the present invention are: adopt copper electromagnetic crystallizer 2, its internal dimension φ100×400m, external dimension φ144×400mm, and set 16 longitudinally along the circumferential side at the place 20mm away from the upper end surface of the crystallizer 2 Equally spaced gaps with a width of 0.4 mm and a length of 280 mm; a high-frequency coil 4 is set at a distance of 50 mm from the top of the crystallizer 2, with 4 turns, its internal size is 154×60 mm, and its external size is 176×60 mm. The frequency of the applied high-frequency power supply is 25kHz, the power is 40kw, and the maximum value of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com