Environment-friendly bottle body recycling equipment

A recycling equipment and an environmentally friendly technology, applied in the field of environmentally friendly bottle body recycling equipment, can solve the problems of inconvenient promotion and use, difficult to remove the adhesive area of packaging tape, affecting the working environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

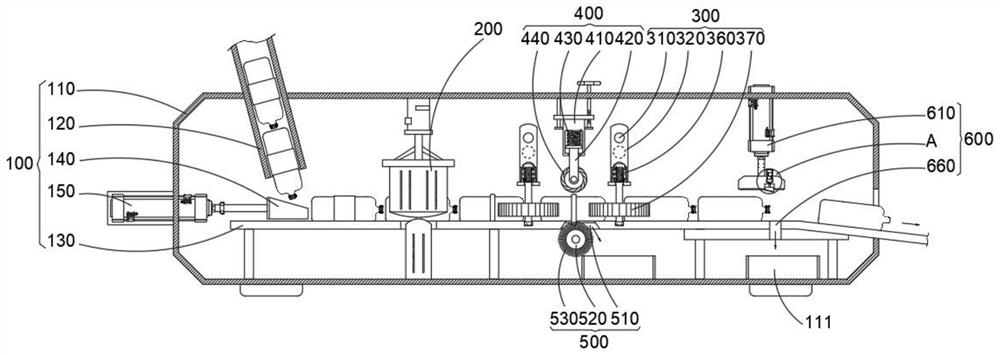

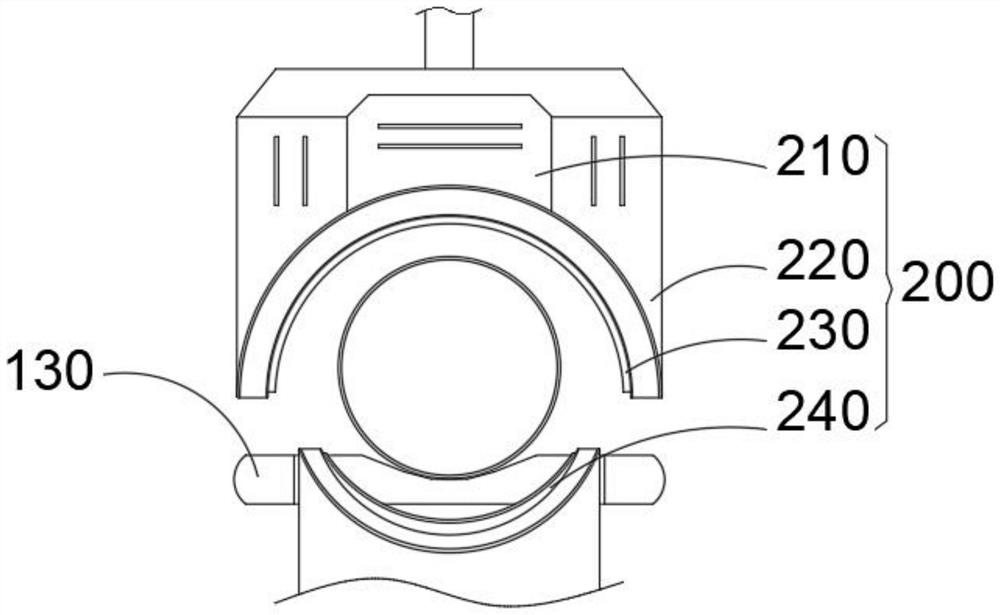

[0045] combine Figure 1-8As shown, the environment-friendly bottle recovery equipment provided by the present invention includes: a feeding mechanism 100, a blanching mechanism 200, a fixed delivery mechanism 300, a crushing mechanism 400, a cleaning mechanism 500 and a cap removal mechanism 600, and the feeding mechanism 100 includes a The box body 110 for operation protection, the feeding hopper 120 installed on the box body 110 for unloading, the feeding table 130 set on the box body 110 for feeding materials, and the pusher located on the feeding table 130 for pushing materials Plate 140 and the electric push rod 150 that is connected and drives the operation of push plate 140, the feeding end of feed hopper 120 can be connected to the assembly line of manual sorting, and also can be connected to the storage bin after sorting, so that the plastic bottles can be evenly distributed. Enter the inside of the box body 110, fall on the feeding table 130 for recycling, and the f...

Embodiment 2

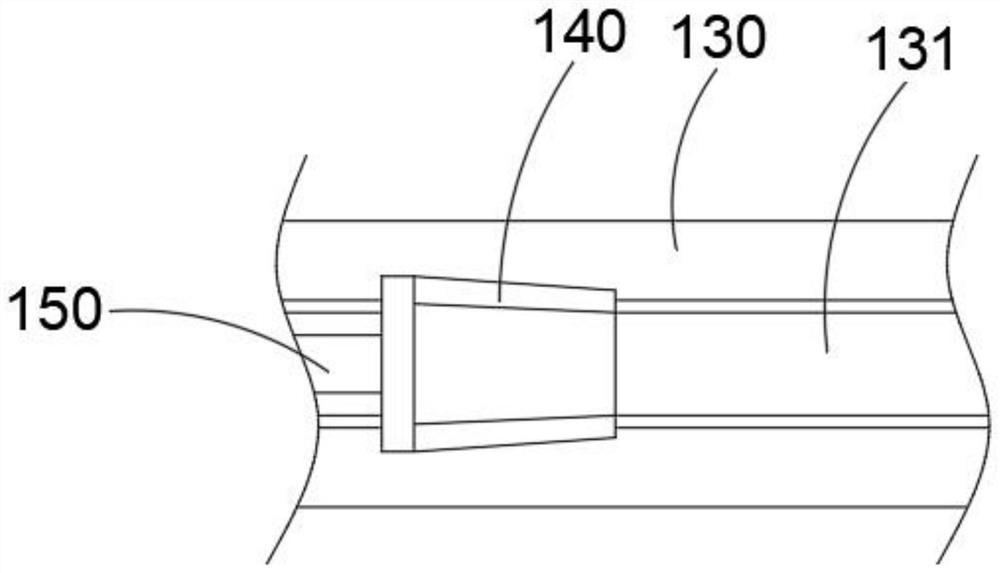

[0052] combine figure 2 As shown, on the basis of the first embodiment, the middle part of the conveying table 130 is provided with a conveying trough 131 for limiting the plastic bottle, and the conveying trough 131 makes the movement of the plastic bottle on the conveying table 130 more stable, preventing the plastic bottle from Slide to the side, and the conveying groove 131 can be set as an arc shape similar to the external structure of the plastic bottle, or can be set as a straight face shape or a combination of the two shapes, and it only needs to have a reasonable limit effect on the plastic bottle, so that The reliability and feasibility of the device are improved.

[0053] On the other hand, the bottom of casing 110 is provided with the collection box 111 that is positioned at the cleaning tank 510 and the lid drop opening 660 below, and the front of casing 110 is provided with the switch door 112 that is positioned at collection box 111 side, can be arranged by col...

Embodiment 3

[0056] combine Figure 7 As shown, on the basis of Embodiment 1, the bottom surface of the capping plate 640 is inclined to the movement direction of the plastic bottle, and the bottom surface of the bottle pressing plate 620 is provided with a pressing thorn 621, through the capping plate 640 with an inclined bottom surface, the bottom surface of the capping plate 640 is inclined. When the plate 640 squeezes the bottle cap, it can apply a tilting force to the bottle cap, and the inclined surface is located above the cap drop opening 660, which greatly facilitates the bottle cap falling into the inside of the cap drop opening 660, making the bottle cap easier to fall off. The bottom surface of the capping plate 640 is provided with anti-slip lines, which can prevent the capping plate 640 from slipping off when squeezing the bottle cap, ensuring the stability and accuracy when squeezing the bottle cap, and the pressing thorns 621 can press the plastic bottle. Prevent the plasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com