Injection molding and printing integrated processing system for food packaging container

A food packaging container and processing system technology, applied in the field of food packaging container injection molding and printing integrated processing system, can solve the problems of reducing the printing quality and printing efficiency of the container, and the low degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

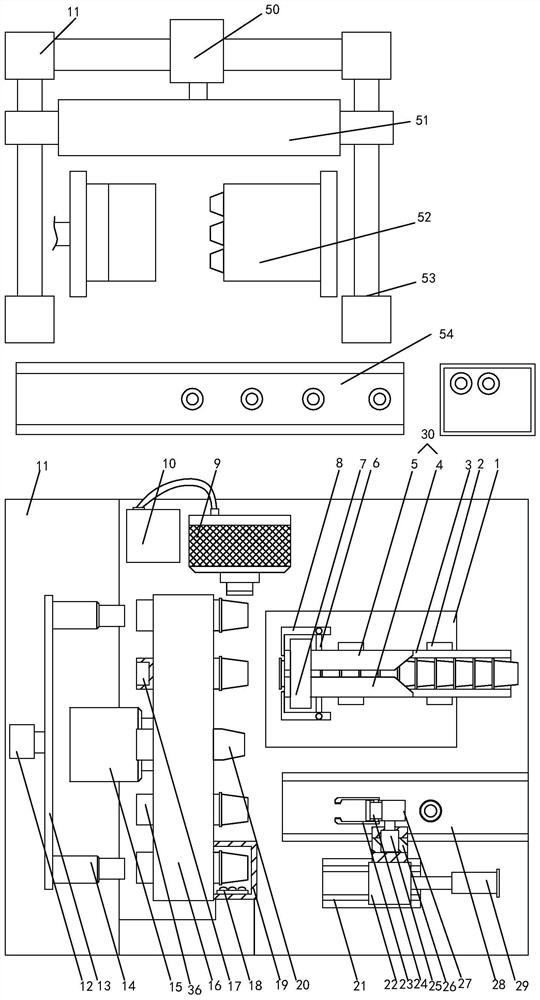

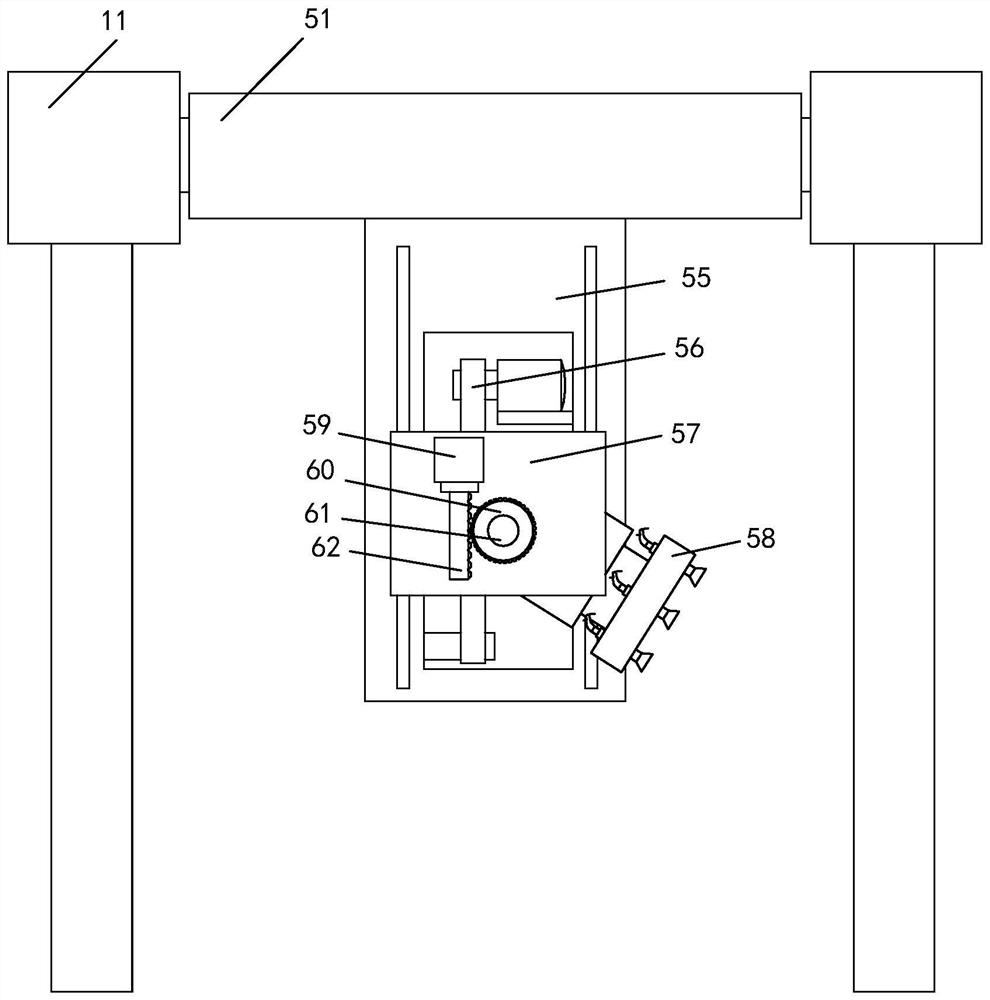

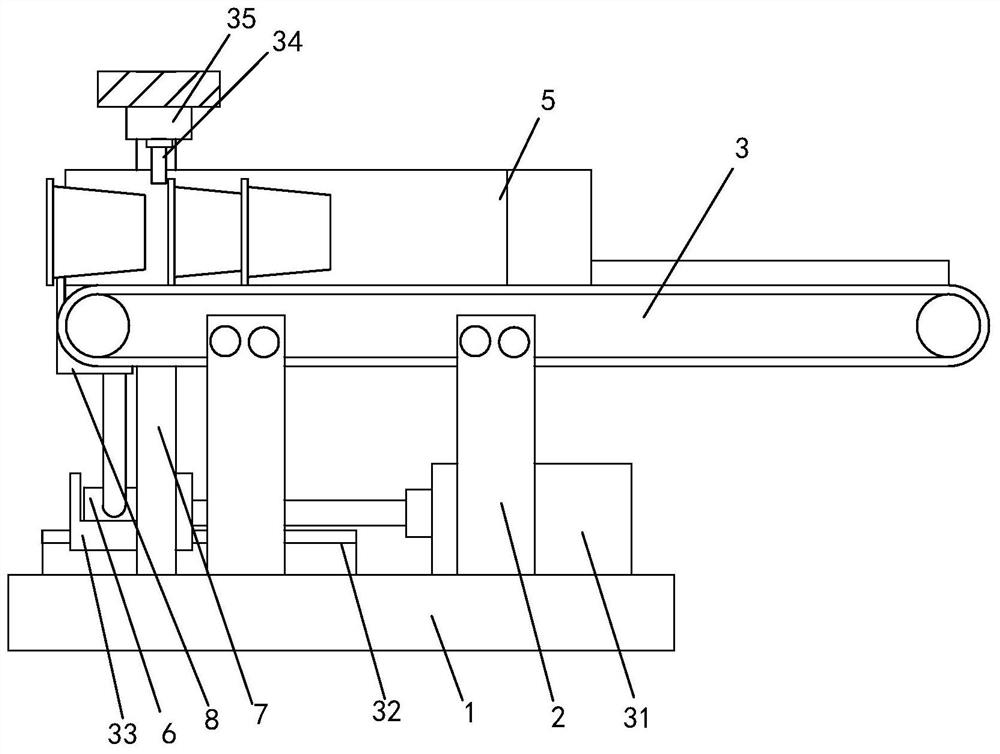

[0040] Such as Figures 1 to 4 As shown, the present invention is an integrated processing system for injection molding and printing of food packaging containers, comprising: a frame 11, a container injection molding device arranged on the frame, and the container injection molding device includes: an injection mold 52 arranged on the frame, The container injection molding conveyor belt 54 on one side of the mold 52, the first slide rail seat 53 arranged on the frame, the first moving seat 51 sleeved on the first slide rail seat 53, the propulsion cylinder arranged on the frame and connected to the moving seat 50. The second slide rail seat 55 located on the first moving seat 51, the belt transmission part 56 provided on the second slide rail seat 55, which is slidably assembled on the second slide rail seat 55 and connected with the belt transmission part 56 The second moving seat 57 , and the container injection and retrieving assembly arranged on the second moving seat 57 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com