Tracheostomy tube body and preparation process thereof

A tracheotomy and intubation technology, applied in the field of tracheotomy intubation tube body and its preparation, can solve the problems of comfort of mucous membrane injury in the trachea, high tube body hardness, water loss, etc. Guaranteed flexibility and low Shore hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

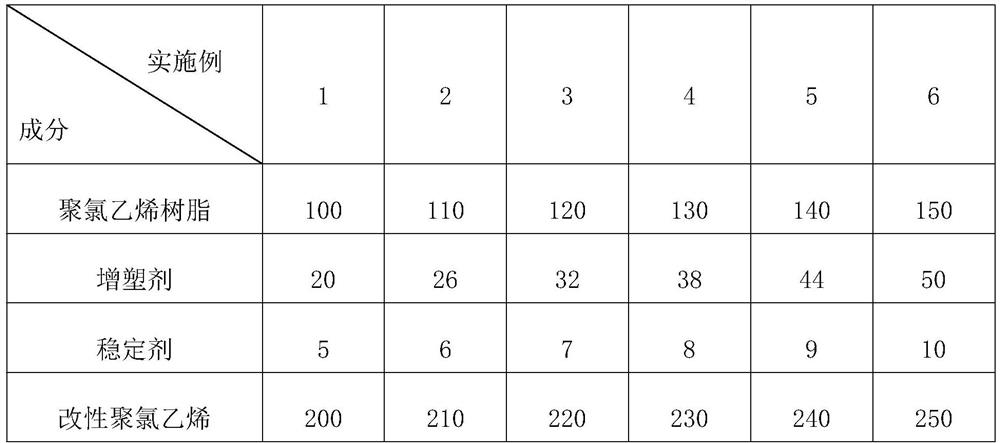

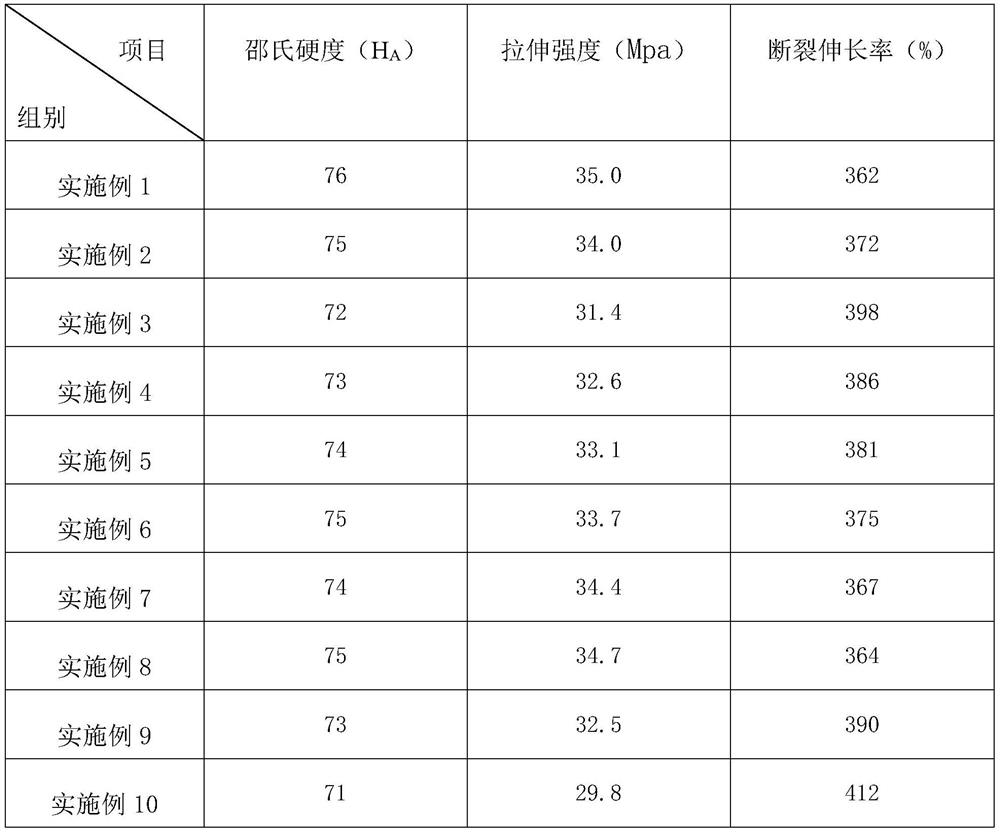

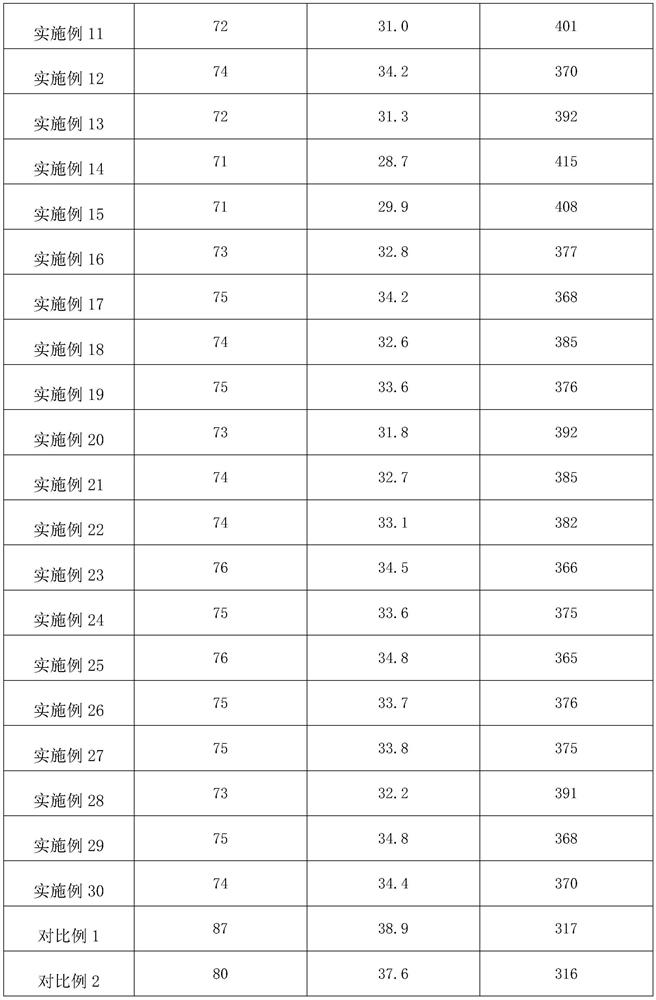

Examples

preparation example 1

[0060] A kind of modified polyvinyl chloride, its preparation steps are as follows:

[0061] a. Modification treatment: first mix polyvinyl chloride resin, modified emulsion and initiator in a weight ratio of 1:0.1:0.005, that is, stir at 80°C for 5min at a speed of 80r / min, and then heat up to 180°C °C, under vacuum conditions, at a speed of 200r / min, stir for 4h to prepare the modified material;

[0062] The modified emulsion is composed of tributyl citrate, tetramethyltetravinylcyclotetrasiloxane, and octamethylcyclotetrasiloxane in a weight ratio of 1: 0.01:1;

[0063] The initiator is sodium trimethylsilanolate;

[0064] b. Softening treatment: Mix the modified material, lubricant and surfactant in a weight ratio of 1:0.1:0.05, that is, stir at a speed of 80r / min for 1h at 80°C to obtain a modified polychloride vinyl.

[0065] The lubricant is calcium stearate;

[0066] The surfactant is coconut acid diethanolamide.

preparation example 2

[0068] A modified polyvinyl chloride, the difference from Preparation Example 1 is that the preparation steps are as follows:

[0069] a. Modification treatment: Stir the polyvinyl chloride resin, modified emulsion and initiator at 90°C at a speed of 80r / min for 7.5min, then raise the temperature to 190°C, and stir at 200r / min under vacuum. The rotating speed, stir 4.5h, make modified material;

[0070] b. Softening treatment: Stir the modified material, lubricant and surfactant at 90°C at a speed of 80r / min for 1.5h to prepare modified polyvinyl chloride.

preparation example 3

[0072] A modified polyvinyl chloride, the difference from Preparation Example 1 is that the preparation steps are as follows:

[0073] a. Modification treatment: Stir the polyvinyl chloride resin, modified emulsion and initiator at a speed of 80r / min for 10min at 100°C, then raise the temperature to 200°C, and stir at a speed of 200r / min under vacuum. Rotating speed, stirring for 5h, obtained modified material;

[0074] b. Softening treatment: Stir the modified material, lubricant and surfactant at 100°C for 2 hours at a speed of 80r / min to obtain modified polyvinyl chloride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com