Large deep foundation protection lock catch steel pipe pile cofferdam structure and construction method thereof

A construction method and technology of steel pipe piles, which are applied in infrastructure engineering, sheet pile walls, buildings, etc., can solve problems such as high safety risks, difficulty in waterproofing and sealing of foundation pit protective structures, and investment in more load-bearing components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

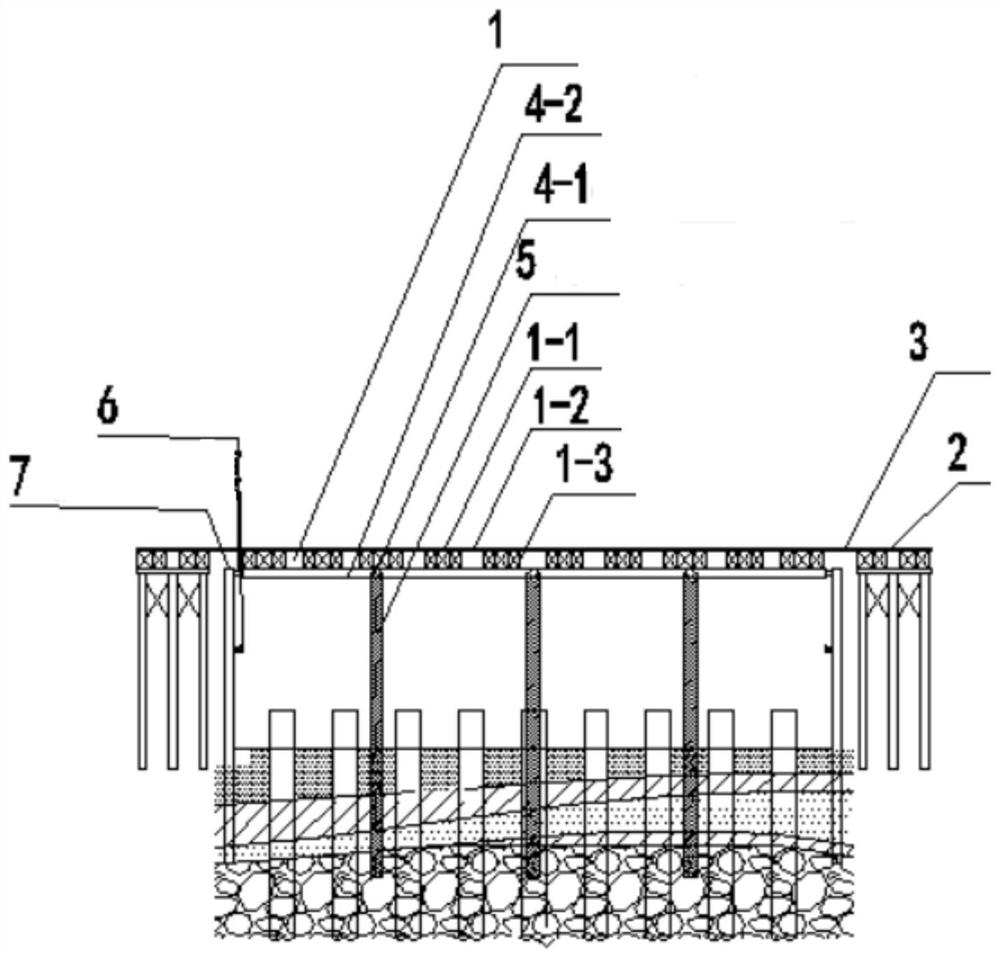

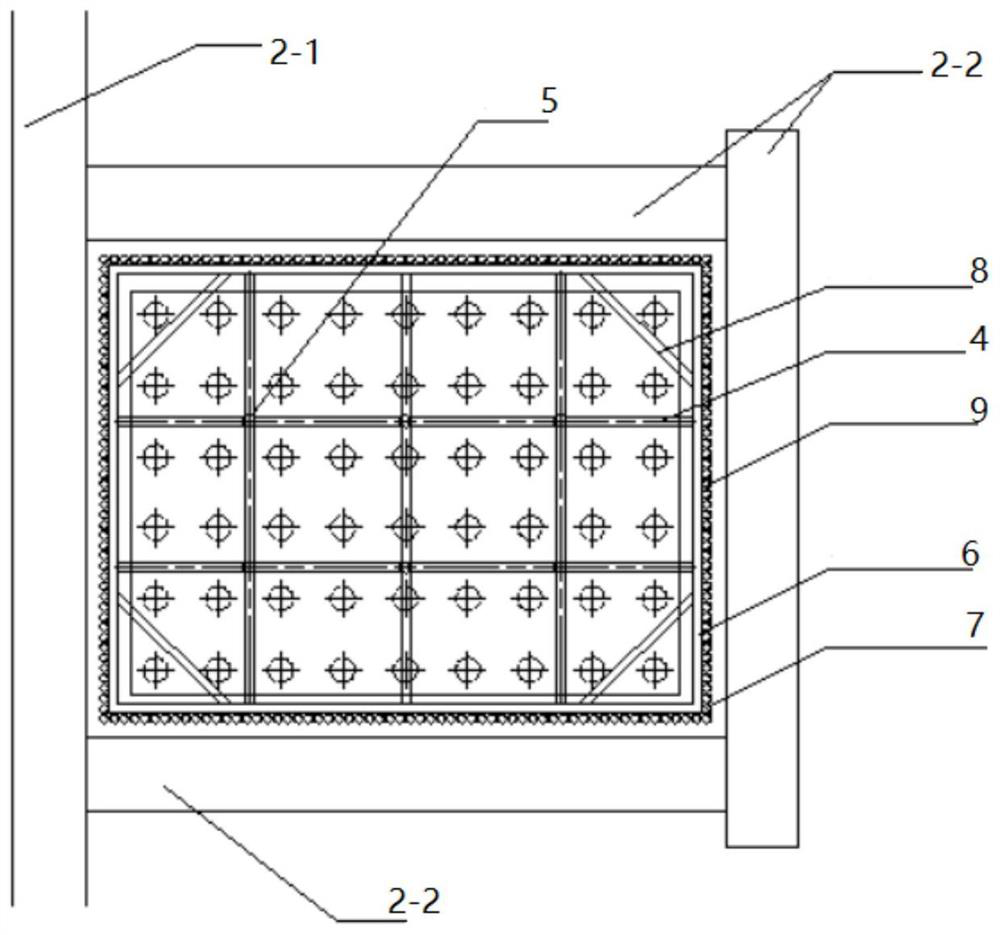

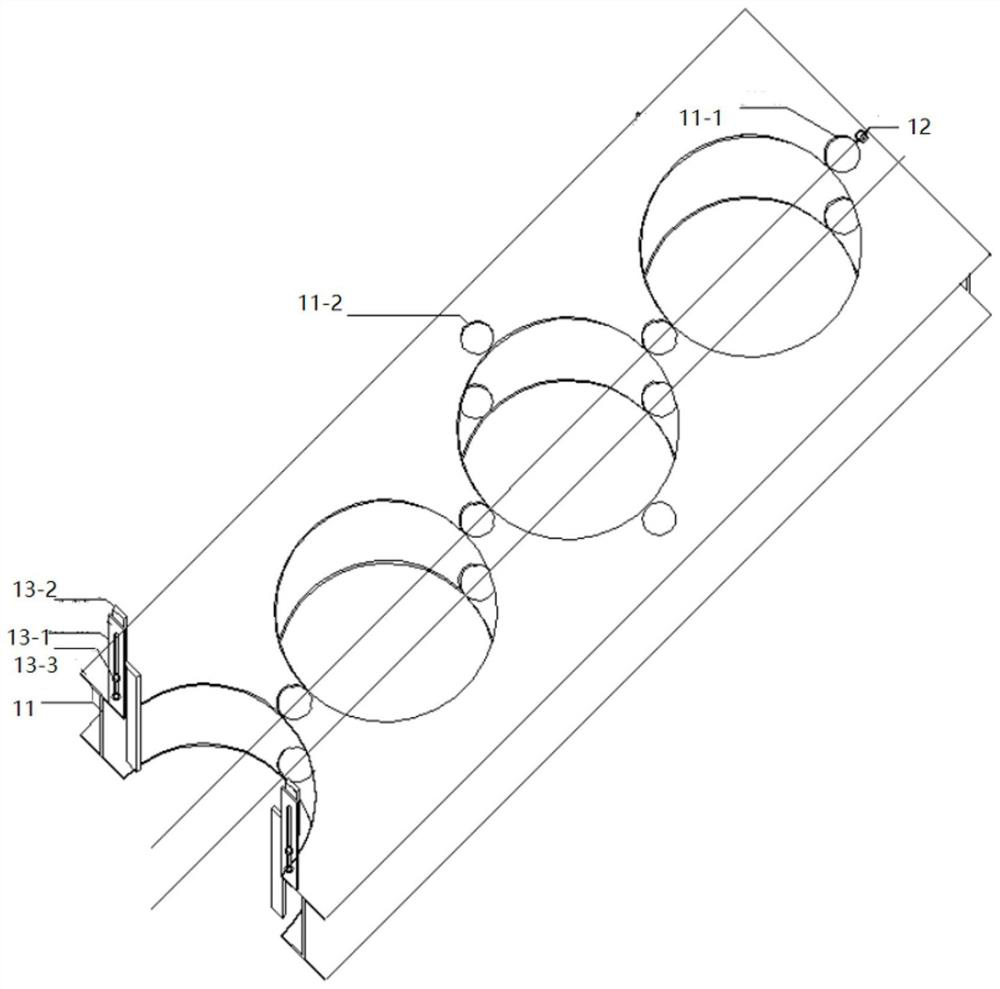

[0040] see figure 1 , figure 1 It is a three-dimensional schematic diagram of a large deep foundation protective locking steel pipe pile cofferdam structure constructed according to the present invention. Such as figure 1 As shown in , the cofferdam structure is composed of a plurality of locking steel pipe piles 7 connected in series end to end, and is also equipped with purlins 6, inner supports 4 and load-bearing piles 5, etc. In addition, the main engineering structure (shown as pouring platform 1 shown in the figure) on the upper part of the purlin 6 and the inner support 4 can also be erec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com