Rectangular waveguide resonant cavity filled with metal mushroom metamaterial

A rectangular waveguide and metal-filled technology, applied in the information field, can solve problems such as unfavorable communication and radar low-loss applications, difficulty in integration, and dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

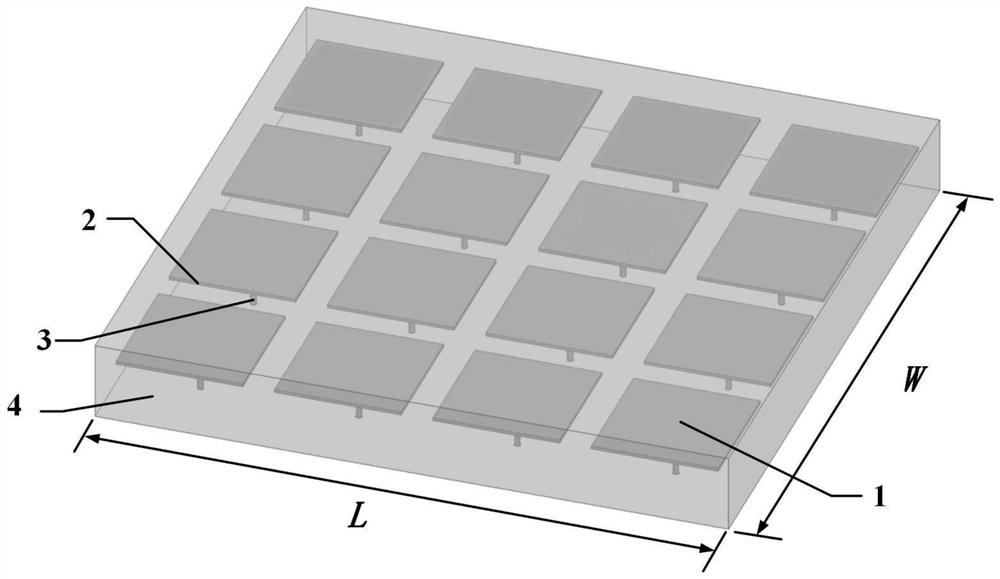

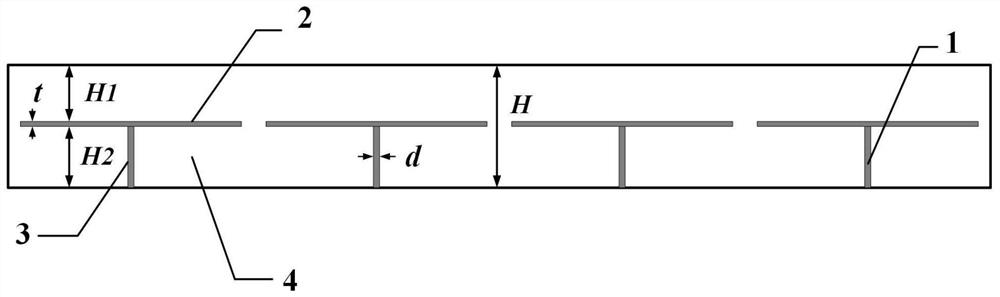

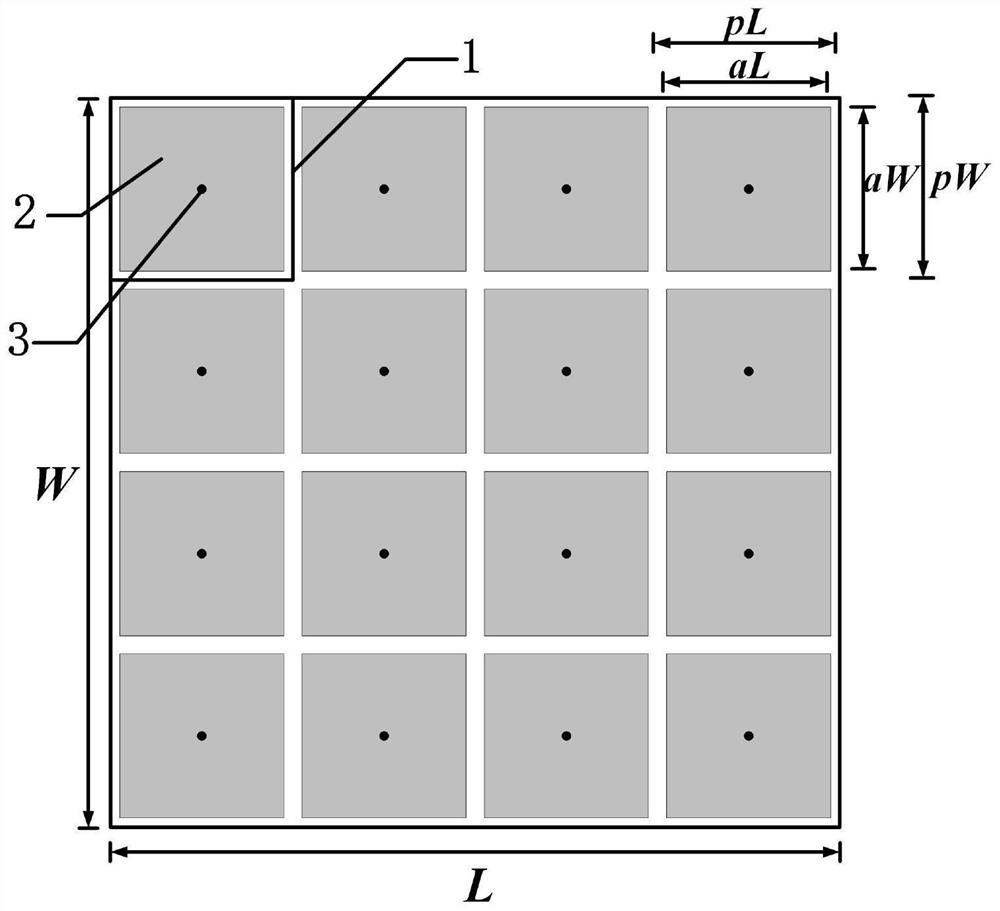

[0032] see Figure 1 ~ Figure 3 , a rectangular waveguide resonant cavity filled with a metal mushroom superstructure material, comprising a rectangular waveguide resonator, the rectangular waveguide resonant cavity is filled with a metal mushroom superstructure material 1: select one inside the rectangular waveguide resonant cavity with the upper and lower The metal surface is parallel to the middle plane, and a metal mushroom superstructure material 1 is filled in the middle plane. The metal mushroom superstructure material 1 is composed of several rectangular metal mushroom patches 2, and each piece of rectangular metal mushroom patch 2 is different. connected, and each of the rectangular metal mushroom patches 2 realizes metal interconnection with the lower surface of the cavity through the metal pillar 3 located in the center, forming an overall structure in the shape of a mushroom.

[0033] The rectangular resonant cavity proposed in this embodiment has a simple structur...

Embodiment 2

[0035] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0036] In this embodiment, the background medium inside the cavity of the rectangular waveguide resonator is air 4 . In order to achieve the requirement of low dielectric loss.

[0037] In this embodiment, when the overall size of the cavity is fixed, by adjusting the height from the middle plane to the lower surface of the cavity, the unit period size of the metal mushroom metamaterial 1, the size of the rectangular metal mushroom patch 2, and the metal post 3 diameter and height of any one or several parameters to realize the control of resonant frequency and Q value of the resonant cavity.

[0038] In this embodiment, the number of the metal pillars 3 is 1 or any reasonable integer greater than 1.

[0039] In this embodiment, the metal mushroom patch 2 of the metal mushroom superstructure material 1 can be, but not limited to, a square metal patch, a rectangular metal ...

Embodiment 3

[0043] In this example, see Figure 1~3 , the rectangular waveguide resonant cavity filled with metal mushroom superstructure material, as can be seen from the figure, the internal length of the cavity is L=40mm, the width W=40mm, and the height H=5mm. Select a middle plane parallel to the upper and lower metal surfaces inside the cavity, and its height to the lower surface of the cavity is H2=3.74mm, and a metal mushroom superstructure material 1 is designed in the middle plane, and the metal mushroom superstructure material 1 contains 4×4 units. Each unit includes a rectangular metal mushroom patch 2 and a metal post 3 located in the center of the rectangular metal mushroom patch 2 , and the rectangular metal mushroom patch 2 realizes metal interconnection with the lower surface of the cavity through the metal post 3 .

[0044] The periodic dimension of the metal mushroom metamaterial 1 is pL=pW=10mm. The rectangular metal mushroom patch 2 is a square metal patch, the late...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com