Greening grass seed cloth production system

A production system and technology of grass seeds, applied in lawn growth, horticulture, botany equipment and methods, etc., can solve the problems of large water consumption, large transportation volume, and high-quality cultivated products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

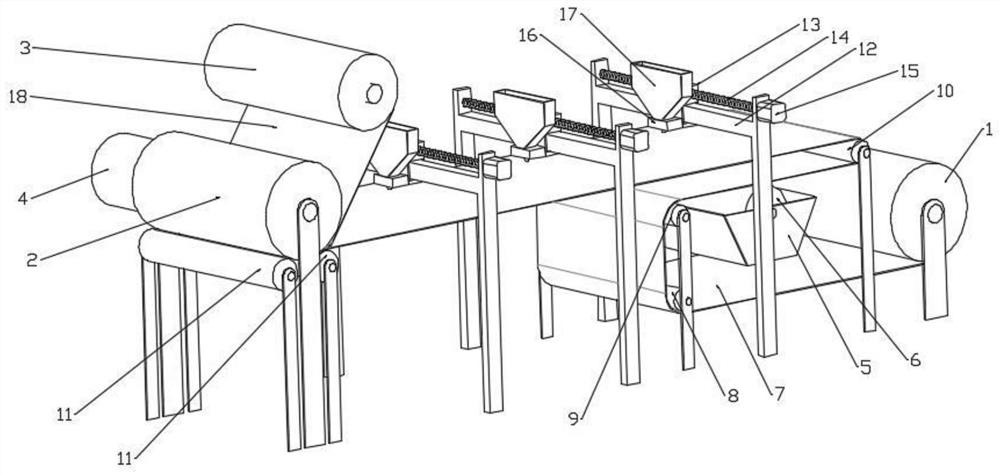

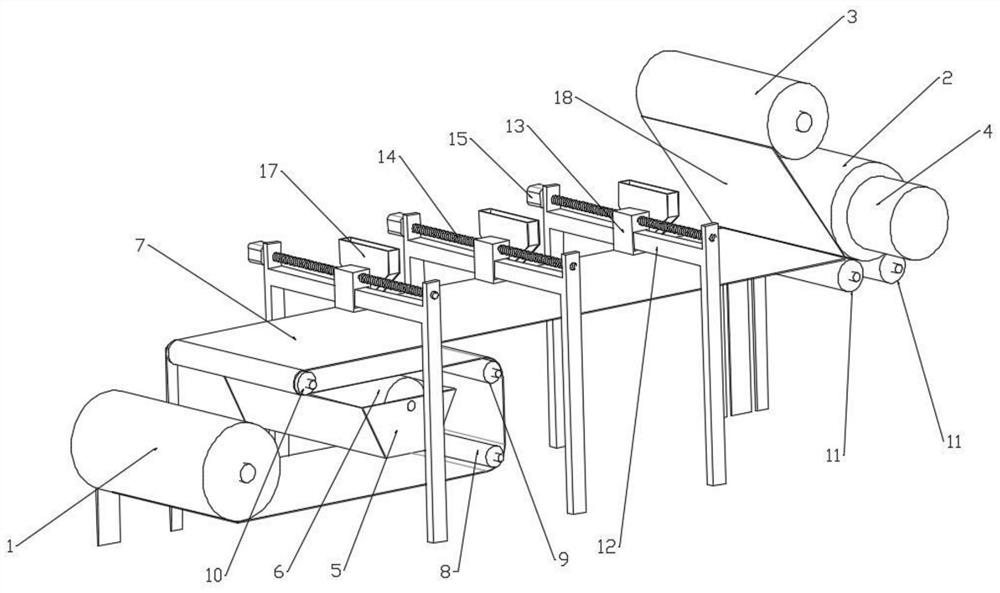

[0018] A green grass seed cloth production system of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0019] combined with Figure 1-Figure 2 , a green grass seed cloth production system, comprising a non-woven reel 1, a finished product reel 2, a paper reel 3 and a rubber roller 6, a non-woven belt 7 arranged on the outside of the non-woven reel 1 One end goes around the first roller 8, the second roller 9 and the third roller 10 in turn, and then winds and connects with the finished roll 2. The non-woven fabric located between the second roller 9 and the third roller 10 A rubber roller 6 is provided below the belt 7, a rubber groove 5 is provided below the rubber roller 6, and a guide rail 12 is provided above the non-woven fabric belt 7 between the third roller shaft 10 and the finished product reel 2, The outside of the guide rail 12 is provided with a slider 13 that can reciprocate along the axis of the guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com