Functionalized porous composite material for hemostasis and application thereof

A porous composite material and functionalized technology, applied in the field of functionalized porous composite materials, can solve the problems of unsatisfactory hemostasis effect of massive hemorrhage, harsh use conditions, and single function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] (1) Polyvinyl alcohol (referred to as PVA) particles are dissolved in deionized water to obtain a uniformly dissolved PVA aqueous solution, and a cross-linking agent TAIC is added to obtain a photocurable solution.

[0027] (2) Generated by Materialize 3-maitc software figure 1 In the porous structure model shown, the porosity is controlled by controlling the diameter of the rod, and the solution is cured by using an SLA photo-curing 3D printer to obtain figure 1 The gradient porous structure is shown.

[0028] (3) Thrombin powder is dissolved in phosphate buffered saline solution, obtains thrombin solution (300UmL -1 , U is the unit of thrombin activity), then the porous material was immersed in the solution for 1 h, and after taking it out, it was placed in a constant temperature and humidity chamber at 40°C for 3 h, so that the porous material could fully interact with the thrombin solution. Subsequently, the material was taken out and placed in 80% ethanol solutio...

experiment example

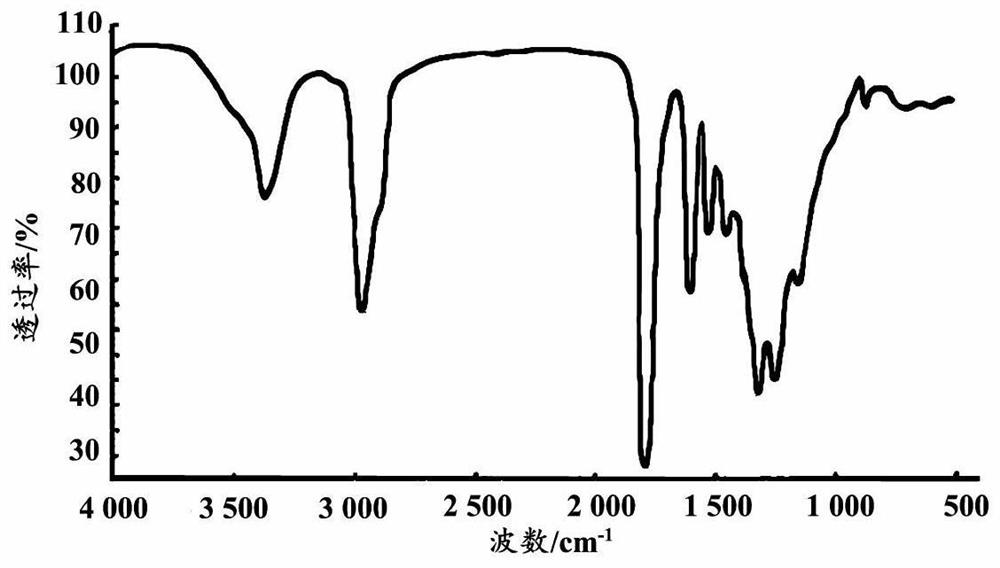

[0030] (1) Chemical structure characterization

[0031] Characterization of the Molecular Structure of Porous Composite Materials by Fourier Transform Infrared Spectroscopy. Divide the material sample into a cube of 10mm×10mm×10mm, test the infrared curve of each sample with an infrared spectrometer, and analyze its characteristic functional groups. The infrared spectrum resolution of the test process is 4cm -1 , the number of scans is 32, and the wavenumber range is 2000cm -1 ~800cm -1 .

[0032] The result is as figure 2 As shown, due to the N-H stretching vibration, there are two possibilities of symmetry and asymmetry, at 3500~2800cm -1 There are two absorption peaks at 1730cm -1 There is a strong peak at 1230~1260cm -1 The place is the characteristic peak of the symmetric and antisymmetric stretching vibration of C-O, 1625cm -1 is the characteristic peak of C=O in COOH.

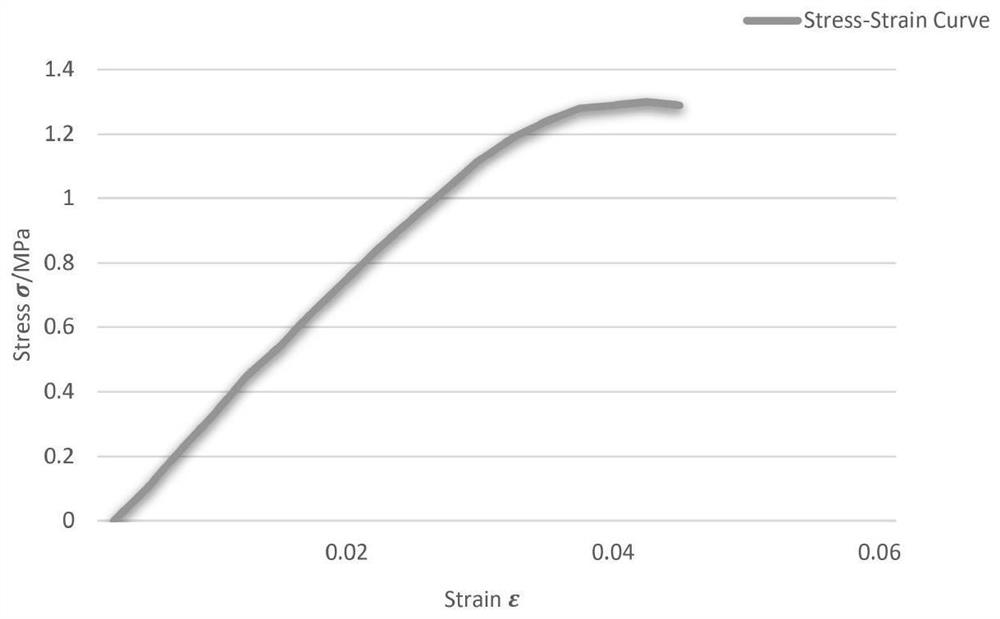

[0033] (2) Mechanical performance test

[0034] During the structural testing, the FR-1001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com