Support pile capable of improving corrosion resistance and construction technology thereof

A construction process and supporting pile technology, which is applied in sheet pile walls, anti-corrosion coatings, infrastructure engineering, etc., can solve problems such as damage, decreased durability of supporting piles, and chemical corrosion on the surface of steel bars.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

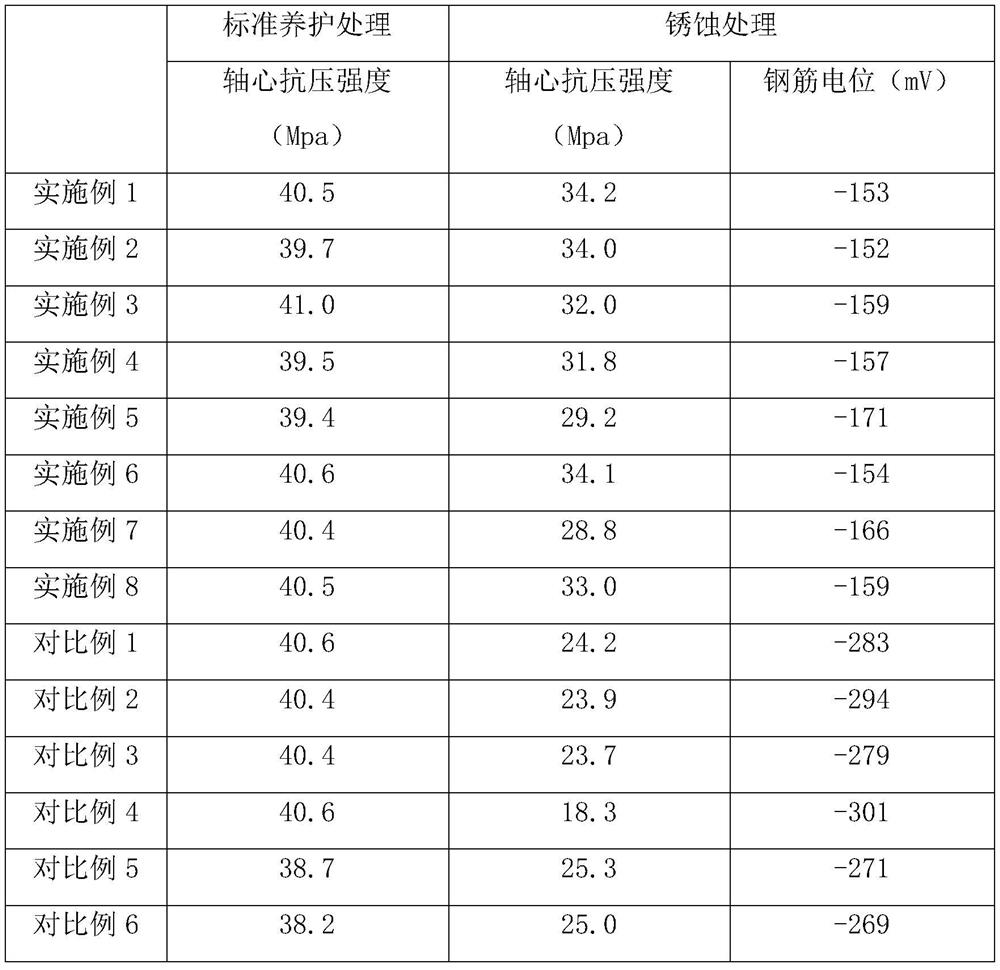

Examples

Embodiment 1

[0069] The application discloses a support pile with improved anti-corrosion performance.

[0070] A support pile for improving anti-corrosion performance, comprising a reinforcement cage and concrete mixture poured into the reinforcement cage, the surface of the reinforcement cage is coated with a corrosion-resistant paint;

[0071] Corrosion-resistant coatings are made from the following raw materials:

[0072] Water 10L, ammonium heptamolybdate 420g, 2-amino-5-nitropyridine 670g, benzotriazole 460g;

[0073] Concrete mixtures are made from the following raw materials:

[0074] 600L of water, 1320kg of cement, 185kg of fly ash, 1010kg of river sand, 1400kg of gravel, 42kg of sodium methyl silicate, and 56kg of sodium hexametaphosphate.

[0075] The application also discloses a construction technique for improving the anti-corrosion performance of the support pile, comprising the following steps:

[0076] a. Material preparation: Prepare the reinforcement cage and concrete...

Embodiment 2

[0093] The difference with Example 1 is that,

[0094] Corrosion-resistant coatings are made from the following raw materials:

[0095] Water 10.2L, ammonium heptamolybdate 380g, 2-amino-5-nitropyridine 630g, benzotriazole 440g;

[0096] Concrete mixtures are made from the following raw materials:

[0097] Water 585L, cement 1300kg, fly ash 175kg, gravel 1380kg, river sand 1000kg, sodium methyl silicate 38kg, sodium hexametaphosphate 52kg.

Embodiment 3

[0099] The difference with Example 1 is that,

[0100] Corrosion-resistant coatings are made from the following raw materials:

[0101] Water 10.5L, ammonium heptamolybdate 450g, 2-amino-5-nitropyridine 700g, benzotriazole 500g;

[0102] Concrete mixtures are made from the following raw materials:

[0103] 620L of water, 1350kg of cement, 200kg of fly ash, 1420kg of gravel, 1030kg of river sand, 45kg of sodium methyl silicate, and 60kg of sodium hexametaphosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com