Epoxy resin latent curing agent and preparation method thereof

A latent curing agent, epoxy resin technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylates, etc., can solve problems such as pollution and reducing reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Weigh 21.2g of 1,3,5-benzenetricarboxylic acid and 41.0g of dimethylimidazole;

[0047] (2) Stir and mix the imidazole compound and the polycarboxylic acid evenly, put it into a ball mill and mill it at 3000r / min for 2h to obtain a powder;

[0048] (3) Cool the powder to room temperature, take out the powder and stir at 50r / min for 0.5h, then put the powder into an oven at 90°C for a solid-state reaction at a constant temperature for 2h;

[0049] (4) Take out the reaction product and put it into a grinder for cooling at 4000r / min for 1h, then stir at 50r / min for 0.75h to obtain a latent curing agent for epoxy resin containing imidazole groups (code: A);

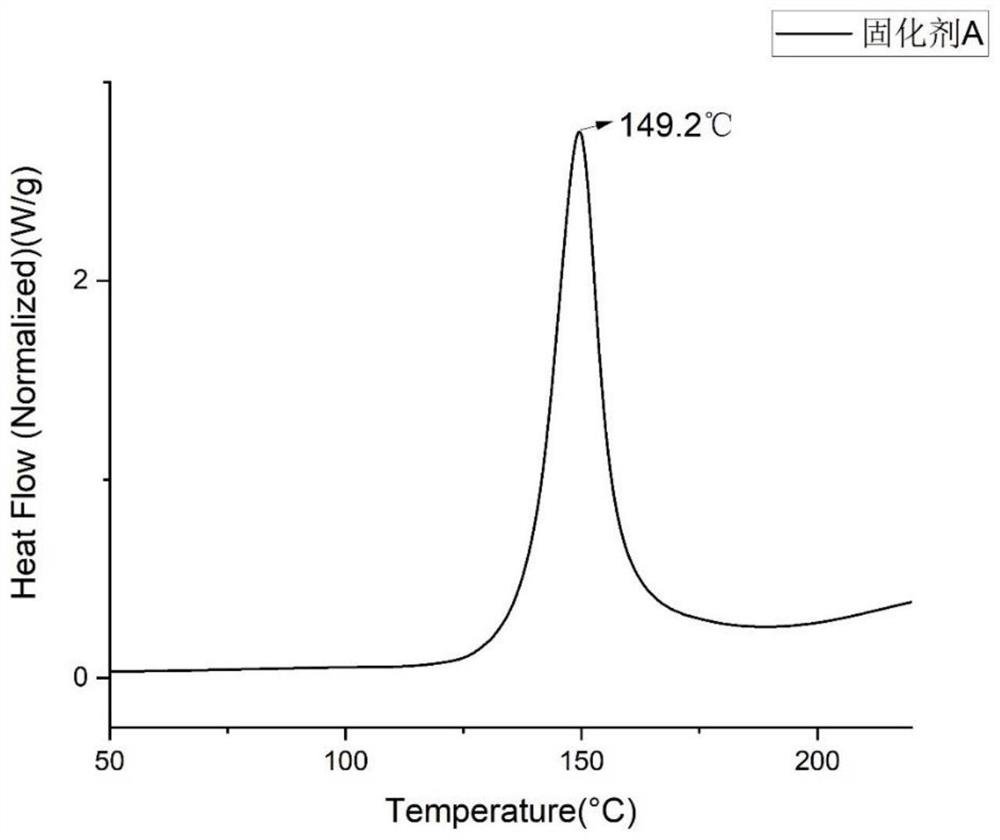

[0050] (5) Add 14g of the above-mentioned modified imidazole curing agent into 80g of E-51 type epoxy resin and mix evenly at 40°C to obtain a latent medium temperature epoxy resin system A. DSC is tested at a heating rate of 10K / min, and the results are as follows figure 1 shown.

Embodiment 2

[0052] (1) Weigh 25.4g of 1,2,4,5-pyrenetetracarboxylic acid and 82g of dimethylimidazole;

[0053] (2) Stir and mix the imidazole compound and the polycarboxylic acid evenly, put it into a ball mill and mill it at 3500r / min for 2h to obtain a powder;

[0054] (3) Cool the powder to room temperature, take out the powder and stir at 120r / min for 0.5h, then put the powder into an oven at 160°C for a solid-state reaction at a constant temperature for 2h;

[0055] (4) Take out the reaction product and put it into a grinder for cooling at 3500r / min for 2h, then stir at 120r / min for 0.5h to obtain a latent curing agent for epoxy resin containing imidazole groups (code: B);

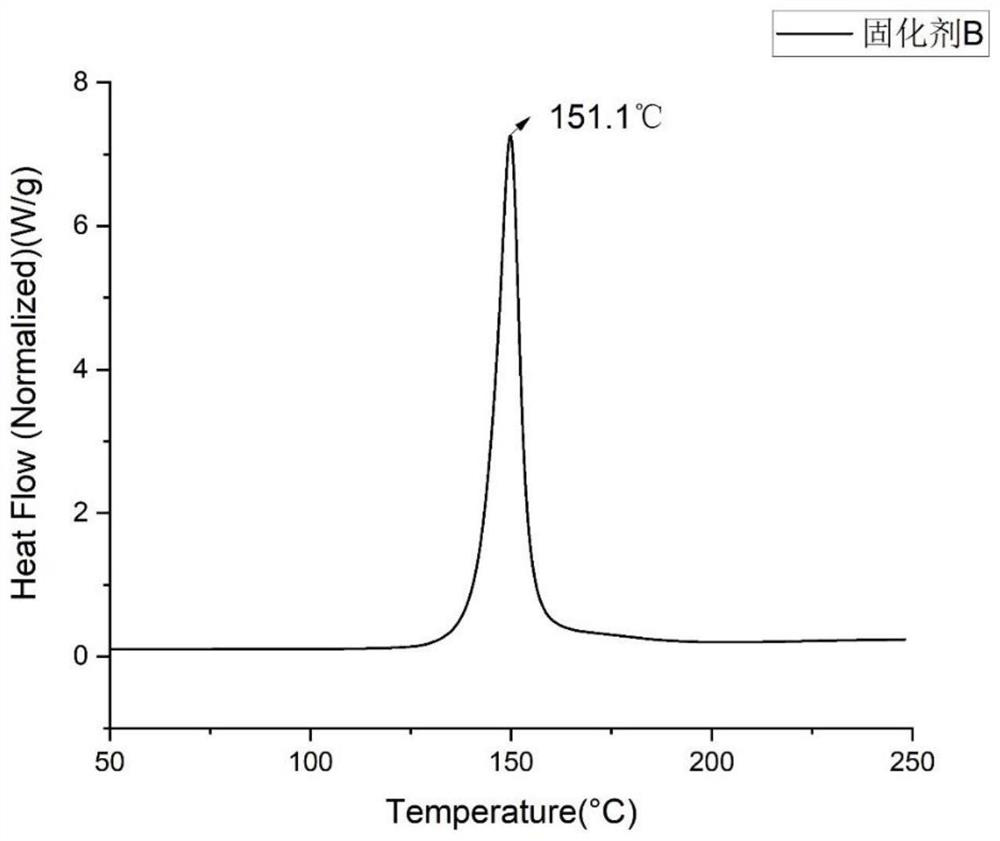

[0056] (5) Add 10g of the above-mentioned modified imidazole curing agent into 100g E-51 type epoxy resin at 60°C and mix evenly to obtain latent medium temperature epoxy resin system B. DSC is tested at a heating rate of 10K / min, and the results are as follows 2 shown.

Embodiment 3

[0058] (1) Weigh mellitic acid 34.2g and dimethylimidazole 61.5g;

[0059] (2) Stir and mix the imidazole compound and the polycarboxylic acid evenly, put into a ball mill and mill at 4500r / min for 4h to obtain a powder;

[0060] (3) Cool the powder to room temperature, take out the powder and stir at 80r / min for 0.1h, then put the powder into an oven at 190°C for a solid-state reaction at a constant temperature for 10h;

[0061] (4) Take out the reaction product and put it into a grinder for cooling at 3000r / min for 1.5h, then stir for 0.5h at 80r / min to obtain a latent curing agent for epoxy resin containing imidazole groups (code: C);

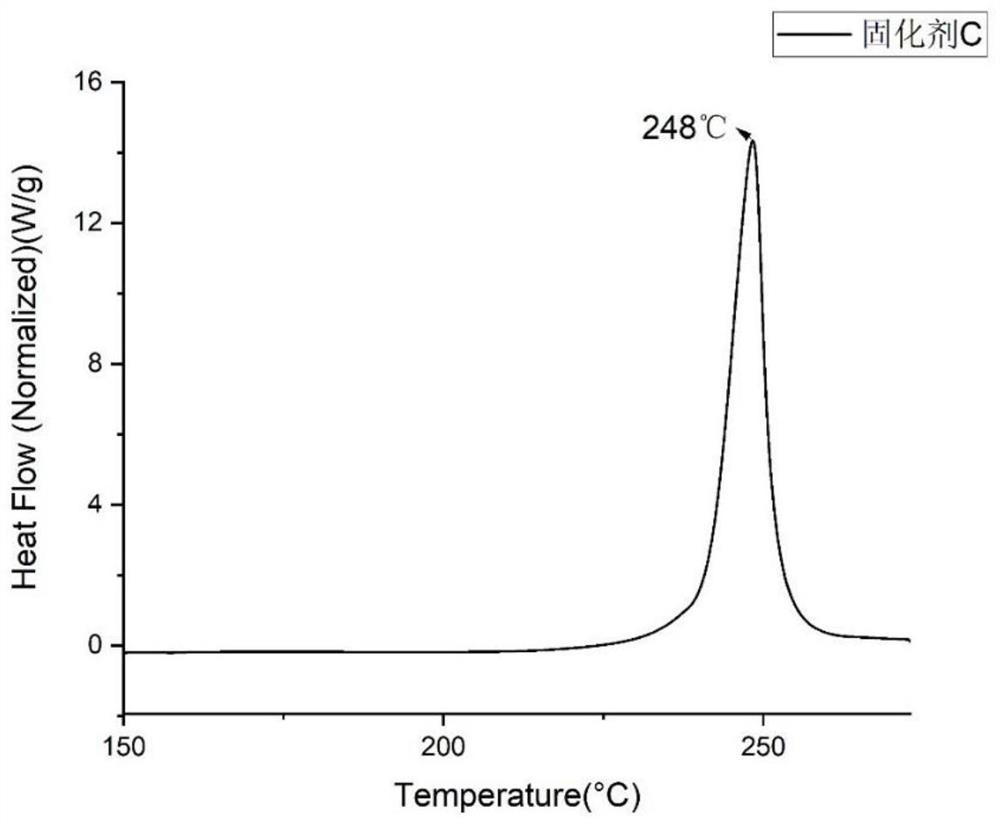

[0062] (5) Add 22g of the above-mentioned modified imidazole curing agent into 80g E-51 type epoxy resin at 60°C and mix evenly to obtain a latent medium-temperature epoxy resin system C. DSC is tested at a heating rate of 10K / min, and the results are as follows image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com