PET/PTT bi-component comfortable stretch yarn preparation process

A preparation process, a technology of stretch silk, which is applied in filament/thread forming, conjugated synthetic polymer man-made filament, textiles and papermaking, etc. Problems such as the stagnation of the application range of elastic wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

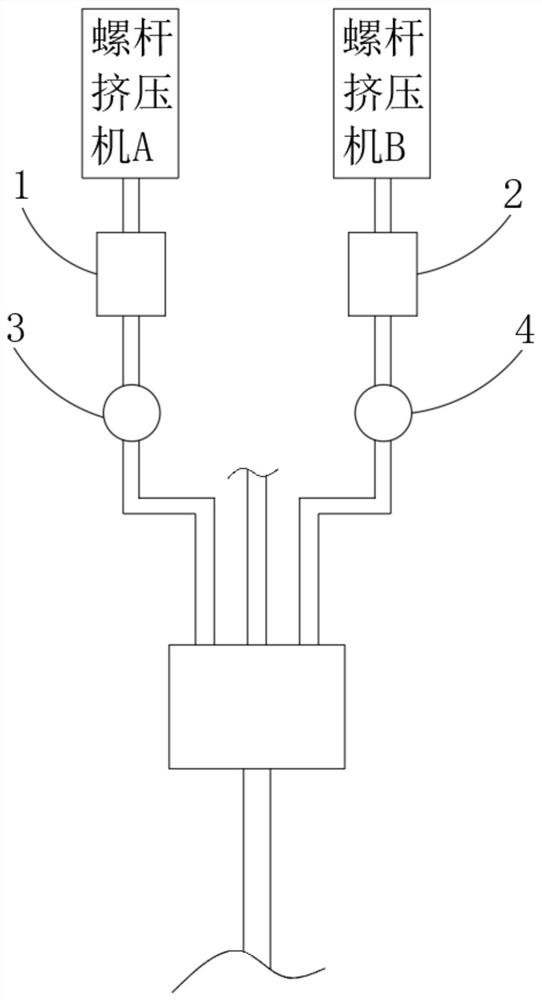

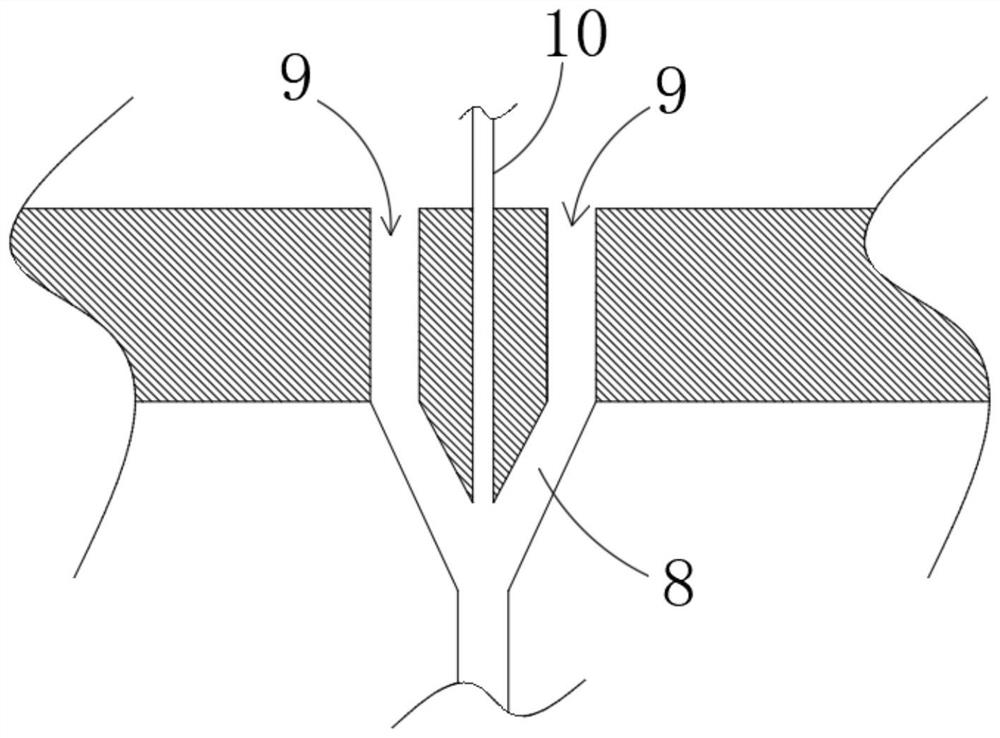

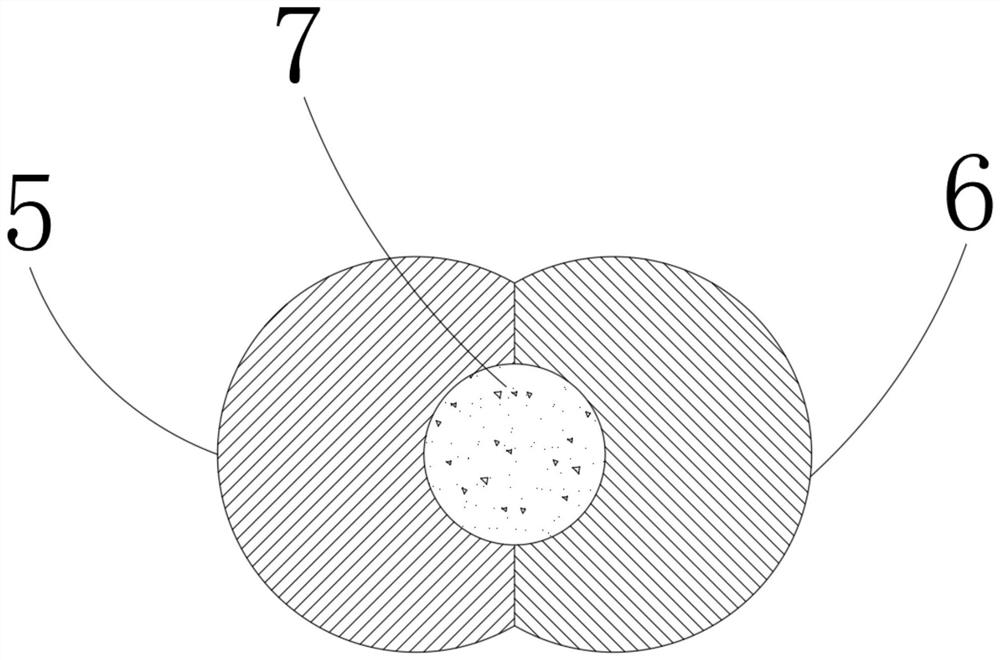

[0029] refer to Figures 1 to 3 : PET / PTT two-component elastic yarn preparation process, including the following steps in order:

[0030] ① Squeeze the PTT slices into the auxiliary box 1 through the screw extruder A after solid-phase thickening treatment and drying treatment;

[0031] ②Extrude the PET chips into the main box 2 through the screw extruder B after pre-crystallization treatment and drying treatment;

[0032] ③ The PTT melt in the sub-box 1 and the PET melt in the main box 2 are merged in the spinneret through the PTT metering pump 3 and the PET metering pump 4 respectively and spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com