Shield grouting method based on shield muck improvement under water-rich sand layer condition

A water-rich sand layer and muck soil improvement technology, which is applied to earth square drilling, underground chambers, shaft equipment, etc., can solve problems such as unbalanced soil pressure mechanism, environmental pollution by waste dregs, and occupation of land resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

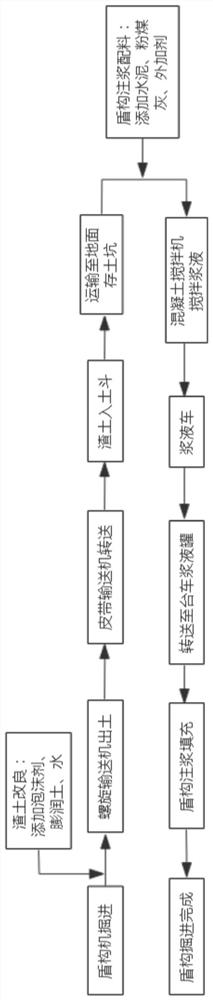

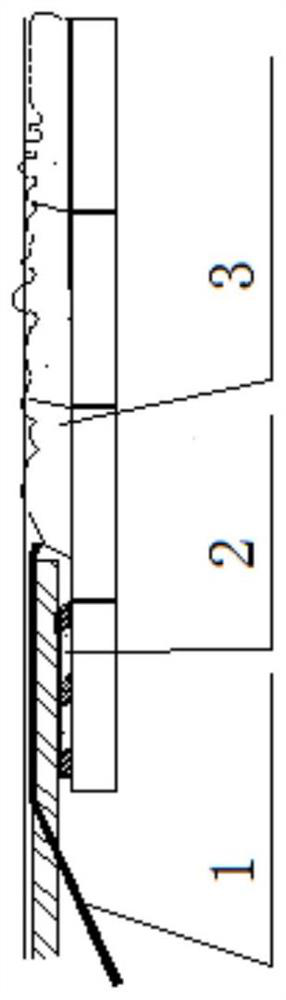

[0033] Such as Figure 1 to Figure 2 As shown, a shield grouting method based on shield dregs improvement under the condition of water-rich sand layer includes the following steps:

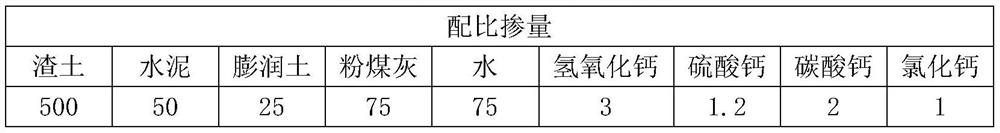

[0034] Step a, according to the geological conditions of the tunnel and the surrounding environmental conditions, the shield tunnel is excavated in the earth pressure balance mode; the soil cut by the cutter is filled with the soil cabin, and the pressure is established by the advancement and extrusion of the shield machine, and the earth pressure is used to build up the pressure. It is balanced with the soil pressure and water pressure of the working surface stratum; at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com