Active and passive support-coupled integral coordination bearing structure for arched roadway and method

An overall coordinated and load-bearing structure technology, which is applied in the direction of supporting the top beam of the mine roof, tunnel, earthwork drilling and mining, etc., can solve the problems of inconvenient disassembly, small bearing capacity, and low recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

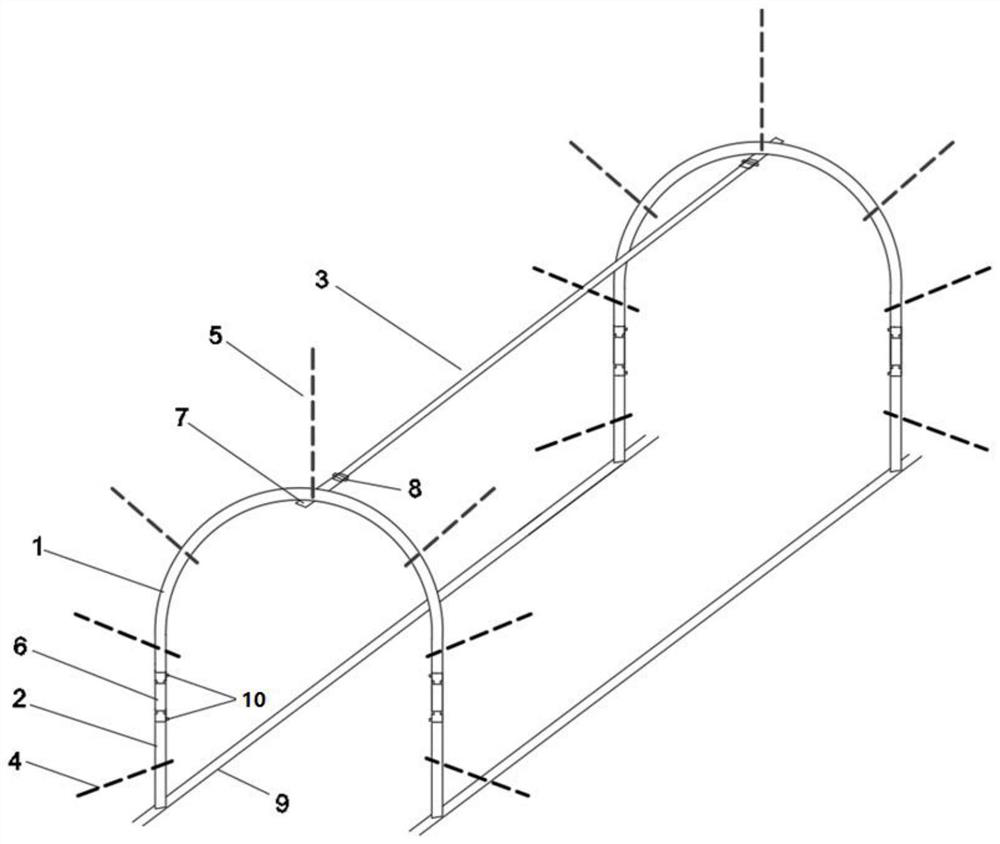

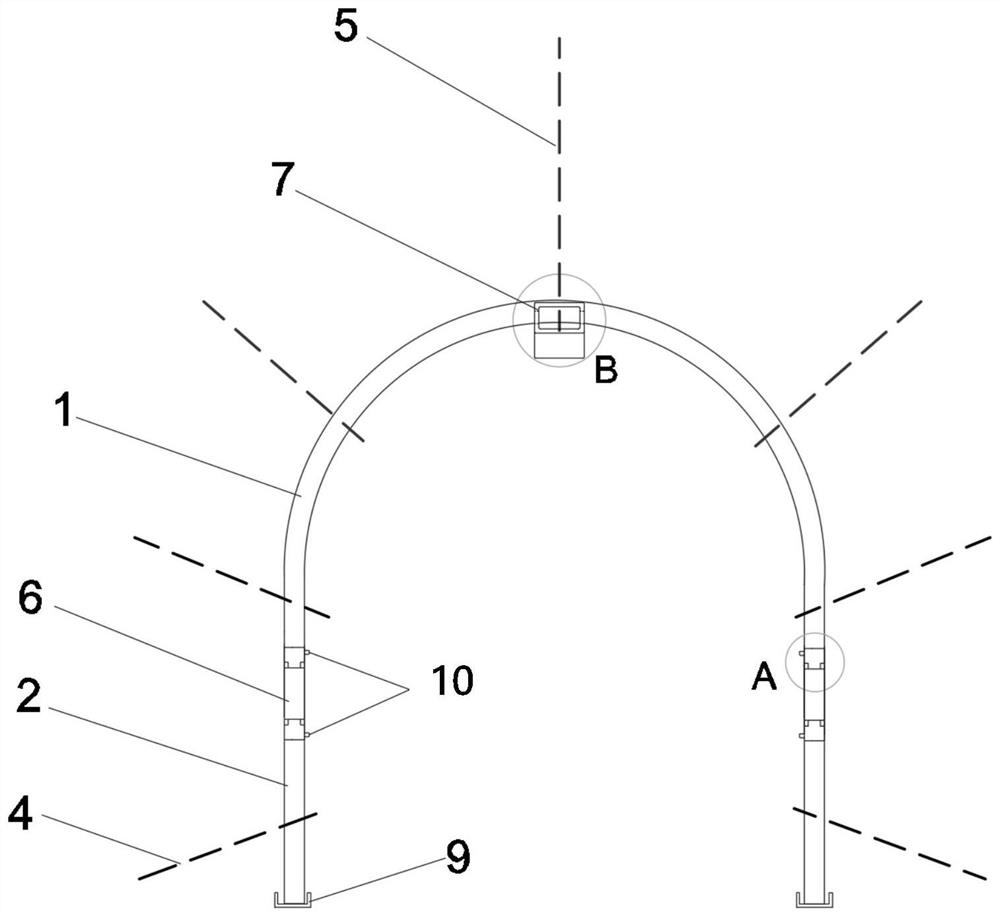

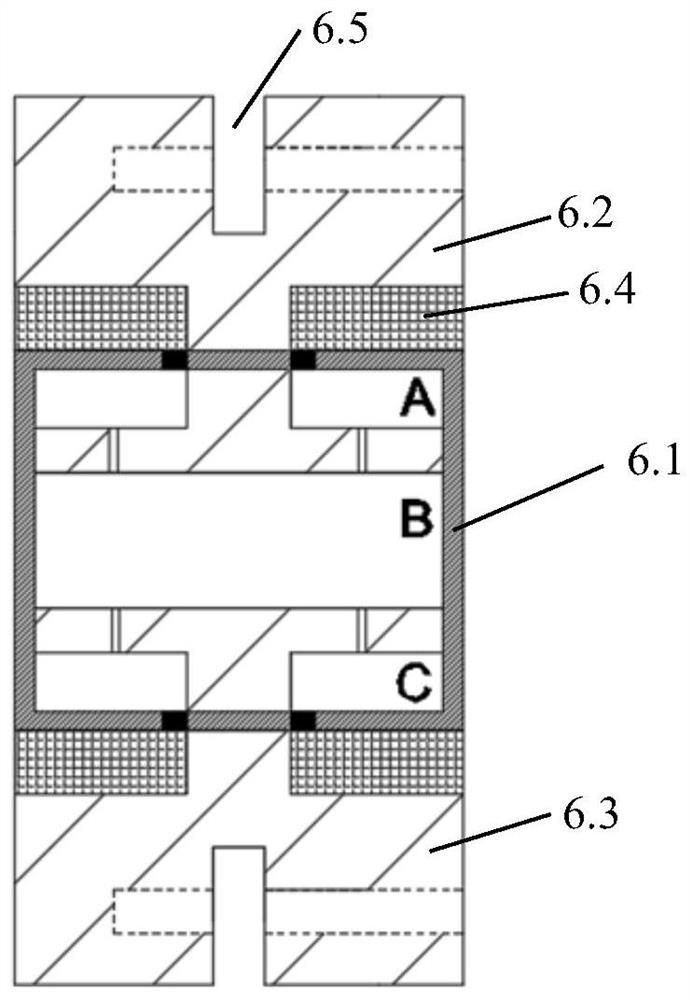

[0077] An arched roadway with active and passive support coupling overall coordinated load-bearing structure, such as Figure 1~7(c) As shown, it includes a plurality of miners’ steel sheds distributed in parallel, and each miners’ steel shed includes a semicircular top beam 1 and a column leg 2 at the bottom of the top beam 1, and both the top beam 1 and the column leg 2 are made of miners’ steel. Five holes are evenly arranged on the beam 1, and the three holes in the center are anchor cable holes, which are used to cooperate with the anchor cable 5 to connect the miner's steel shed with the roadway, and the remaining two holes are anchor holes, which are used to connect with the anchor rod 4 Cooperate to connect the miner's steel shed with the roadway; each column leg 2 has an anchor hole on the web plate in the middle, which is used to cooperate with the anchor rod 4 to connect the column leg 2 with the roadway. Tightening nuts, trays and backing plates, pre-tightening nut...

Embodiment 2

[0084] An arch roadway active and passive support coupling overall coordination load-bearing structure, as shown in embodiment 1, the difference is that the longitudinal connection device includes several-shaped steel 7 and channel steel B 3 between the sheds, several several-shaped steel 7 The opening of the font faces upward to form a limit groove 7.1, and the center of the top beam 1 is embedded in the limit groove 7.1. There is a circular hole in the center of the limit groove 7.1, which is used in conjunction with the anchor cable hole in the center of the top beam 1 ;

[0085] The channel steel B 3 between the sheds is located between two adjacent steel sheds for miners. There is a round hole A at both ends of the channel steel B 3 between the sheds, and a round hole B 7.2 is opened at the two ends of the glyph steel. The hole A and the round hole B 7.2 are connected together by a pin 8 .

Embodiment 3

[0087] An overall coordinated load-bearing structure of an arched roadway with active and passive support coupling, as shown in Embodiment 2, the difference is that the width of the limiting groove 7.1 is slightly larger than the web width of the top beam 1, so that the top beam 1 Embedded in the limit groove 7.1, after embedding, the anchor cable hole in the center of the top beam 1 corresponds to the circular hole in the center of the limit groove 7.1, the anchor cable is installed, and the two ends of the two-end flanges of the girder steel 7 The width is slightly smaller than the width of the web of the channel steel B 3 in the shed. The channel steel B is connected with the several-shaped steel, so as to realize the connection between two adjacent miners' steel sheds and form a whole.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com