Light steel concrete prestress combined type wind power tower drum section and wind power tower thereof

A wind power tower and prestressing technology, applied in the field of wind power tower structure, can solve the problems of inconvenient assembly, inability to design the tower's wind resistance, earthquake resistance, shear resistance, and transportation inconvenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

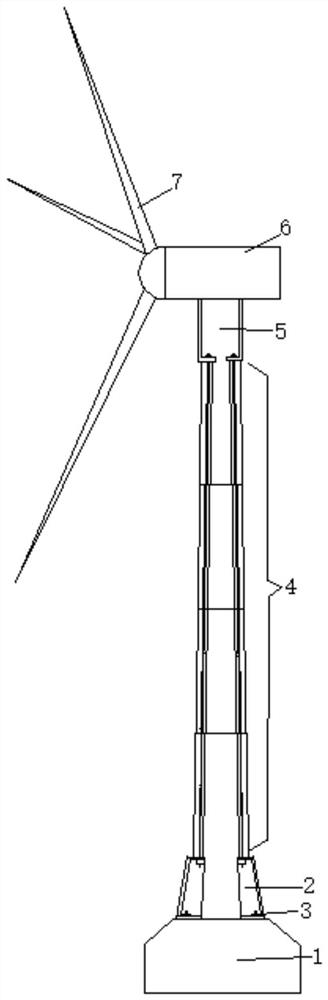

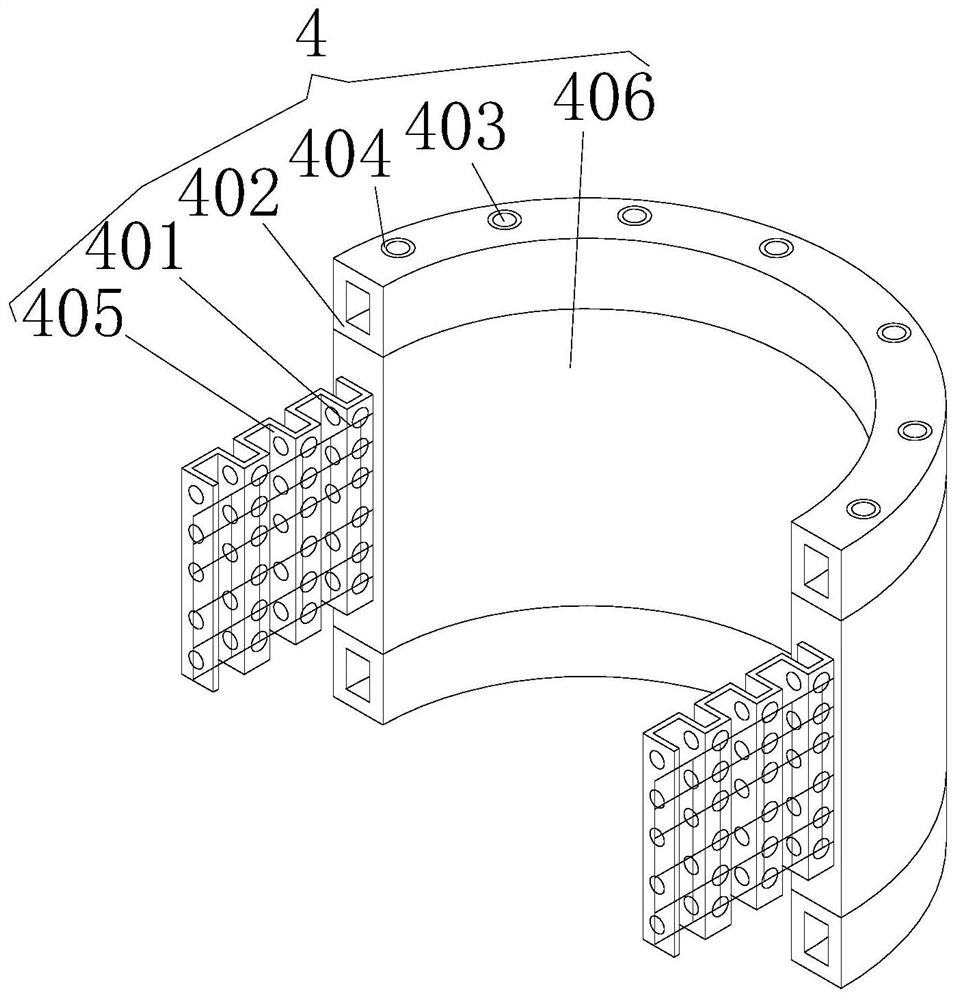

[0037] Such as Figure 1~4 A light-steel concrete prestressed combined wind power tower section is shown, including several arc-shaped prefabricated tower sections spliced with each other. The end faces of the prefabricated tower sections can be semi-circular or 1 / 3 circular. Or 1 / 4 ring, the present embodiment takes the semi-circular ring as an example, each piece of prefabricated tower section segment 4 all includes arc-shaped plates and light steel pipes 402 fixedly installed on the upper and lower sides of the arc-shaped plates by welding, light steel The end faces of the steel pipes 402 are square, and the light-steel steel pipes 402 arc-shaped end faces are provided with stress holes 404 that are convenient for piercing the prestressed tendons 403. The steel mesh 401 and the concrete 406 poured on the outside of the steel mesh 401, the corrugated steel plate 405 is provided with through holes to facilitate mutual communication between the two sides of the corrugated st...

Embodiment 2

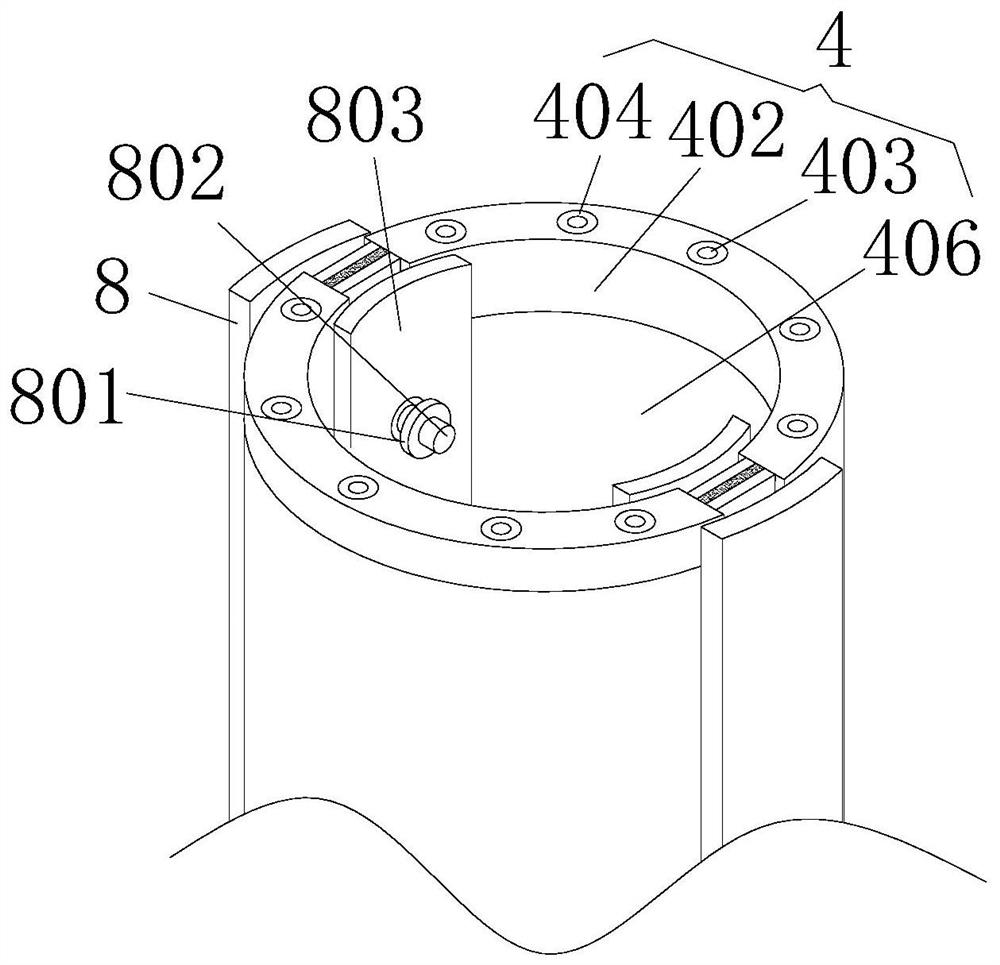

[0047] Such as Figure 1-7 The difference between Embodiment 3 and Embodiment 1 of a light steel concrete prestressed combined wind power tower section shown is that the side of the outer steel plate formwork 8 and the inner steel formwork 802 facing the prefabricated tower section segment 4 are all fixedly connected. There is a fixed rod 804, and the light steel pipe 402 is provided with a fixed hole that is compatible with the fixed rod 804. The outer surface of the fixed rod 804 is provided with a built-in groove 806, and the internal rotation of the built-in groove 806 is connected with a clamping plate 805, and the built-in groove 806 A spring 807 is fixedly connected to the inside of the spring 807, and one end of the spring 807 that is not in contact with the built-in groove 806 is fixedly connected to the clamping plate 805, and the clamping plate 805 is set obliquely. The fixed rod 804 is inserted into the fixed hole provided by the light steel pipe 402. At this time,...

Embodiment 3

[0053] Such as Figure 8 The difference between Embodiment 3 and Embodiment 1 of a light-steel concrete prestressed combined wind power tower section shown is that the end face of the prefabricated tower section is 1 / 4 ring. Adjacent prefabricated tower sections are overlapped and fixedly connected through the cooperation of outer steel formwork, inner steel formwork, nuts and screws. The assembly method of the light steel concrete prestressed combined wind power tower section is the same as that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com