Backflow type waste gas incinerator and environment-friendly waste gas treatment method thereof

A technology of incinerator and waste gas, which is applied in the field of backflow waste gas incinerator and its environmental protection treatment of waste gas, and can solve the problems such as the inability to achieve zero discharge of waste gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

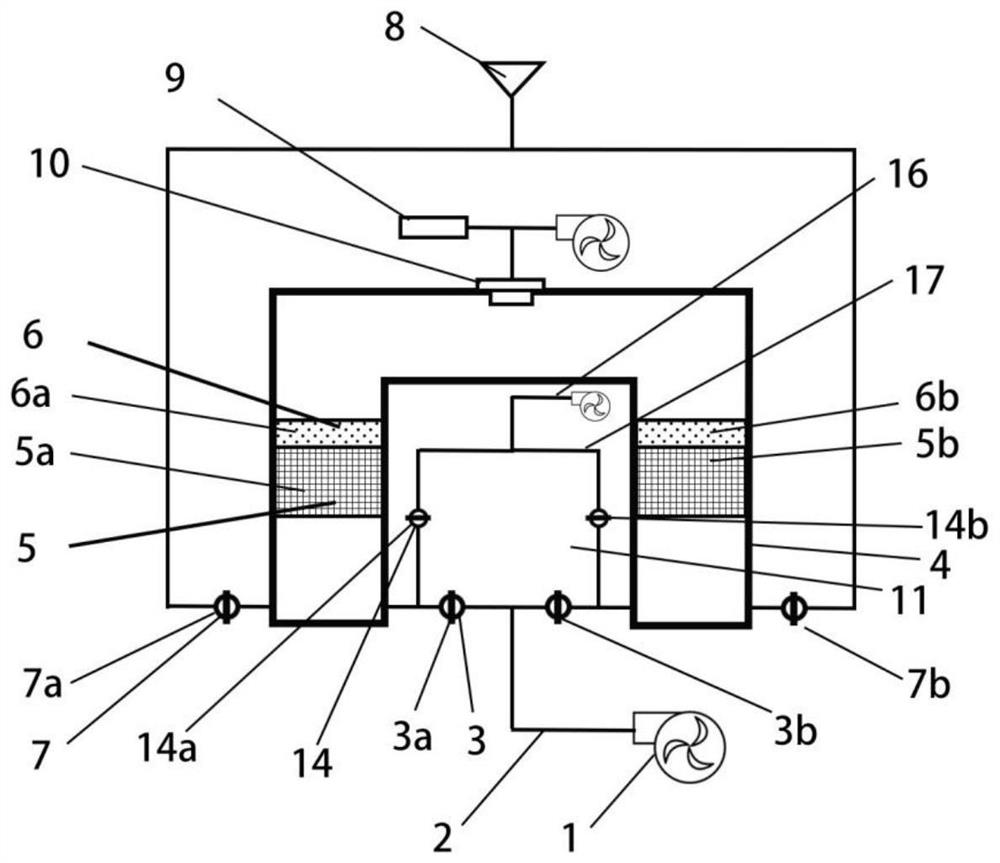

[0033] refer to figure 1 , a backflow type waste gas incinerator, the incinerator is provided with a waste gas inlet pipe 2, a clean air discharge port 8, a U-shaped heating chamber 4 is arranged in the incinerator, the U-shaped heating chamber 4 is connected inside, and a group of The heat storage layer 5 is provided with a burner 10 on the top of the U-shaped heating chamber 4, and the burner 10 is connected with the natural gas pipeline 9, and the waste gas inlet pipe 2 is respectively connected to one side of the two ends of the U-shaped heating chamber 4, and a Intake valve 3, the other side of the two ends of the U-shaped heating chamber 4 are connected to the clean air discharge port 8 through pipelines, and an outlet valve 7 is provided at the connection of both ends, and the inlet valves 3 at different ends of the U-shaped heating chamber 4 are opened during use and air outlet valve 7, so that the exhaust gas can enter any end of the U-shaped heating chamber 4 from th...

Embodiment 2

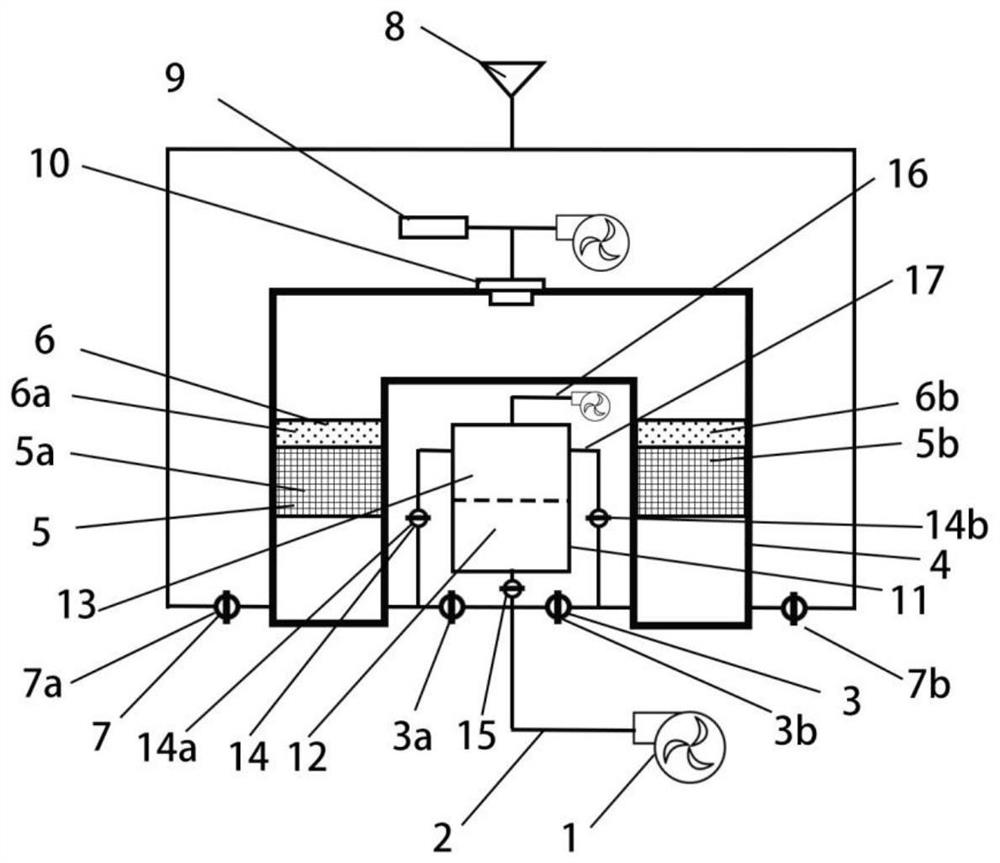

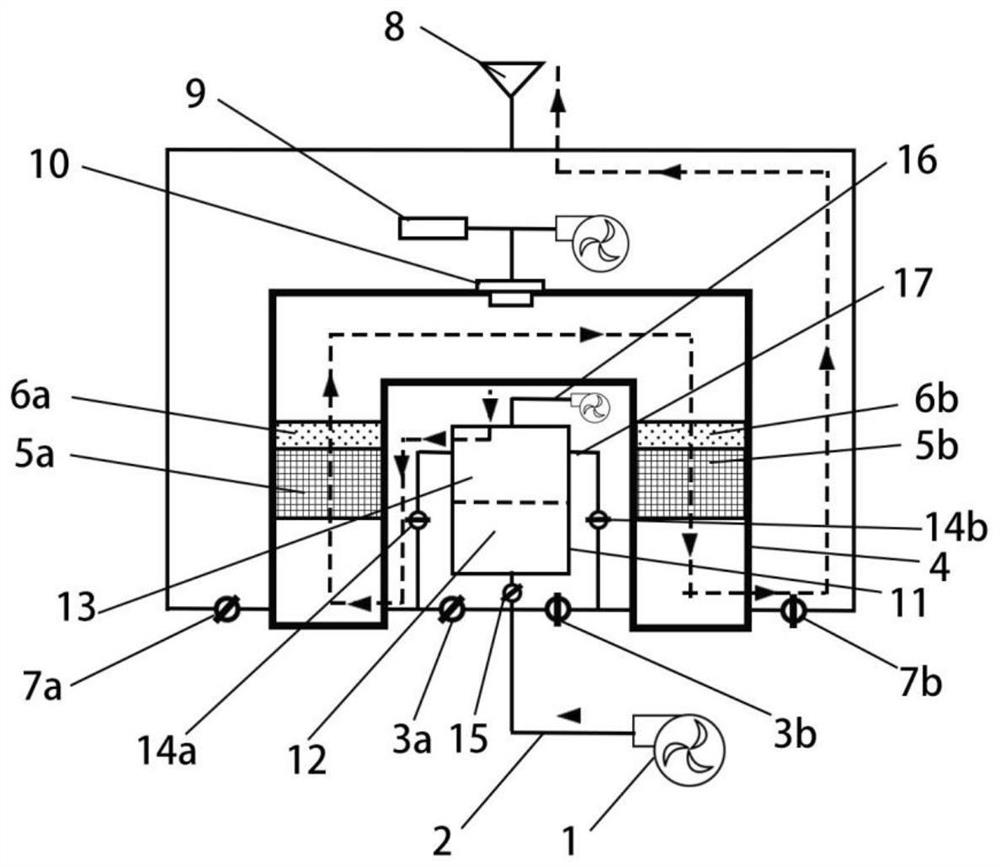

[0043] refer to Figure 2-6 , a backflow type waste gas incinerator, the incinerator is provided with a waste gas inlet pipe 2, a clean air discharge port 8, a U-shaped heating chamber 4 is arranged in the incinerator, the U-shaped heating chamber 4 is connected inside, and a group of The heat storage layer 5 is provided with a burner 10 on the top of the U-shaped heating chamber 4, and the burner 10 is connected with the natural gas pipeline 9, and the waste gas inlet pipe 2 is respectively connected to one side of the two ends of the U-shaped heating chamber 4, and a Intake valve 3, the other side of the two ends of the U-shaped heating chamber 4 are connected to the clean air discharge port 8 through pipelines, and an outlet valve 7 is provided at the connection of both ends, and the inlet valves 3 at different ends of the U-shaped heating chamber 4 are opened during use and air outlet valve 7, so that the exhaust gas can enter any end of the U-shaped heating chamber 4 from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com