High-precision optical path debugging device and debugging method thereof

A high-precision, optical path technology, applied in the field of optical optical path, can solve the problems of time-consuming, error, easy attenuation of auxiliary light source intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

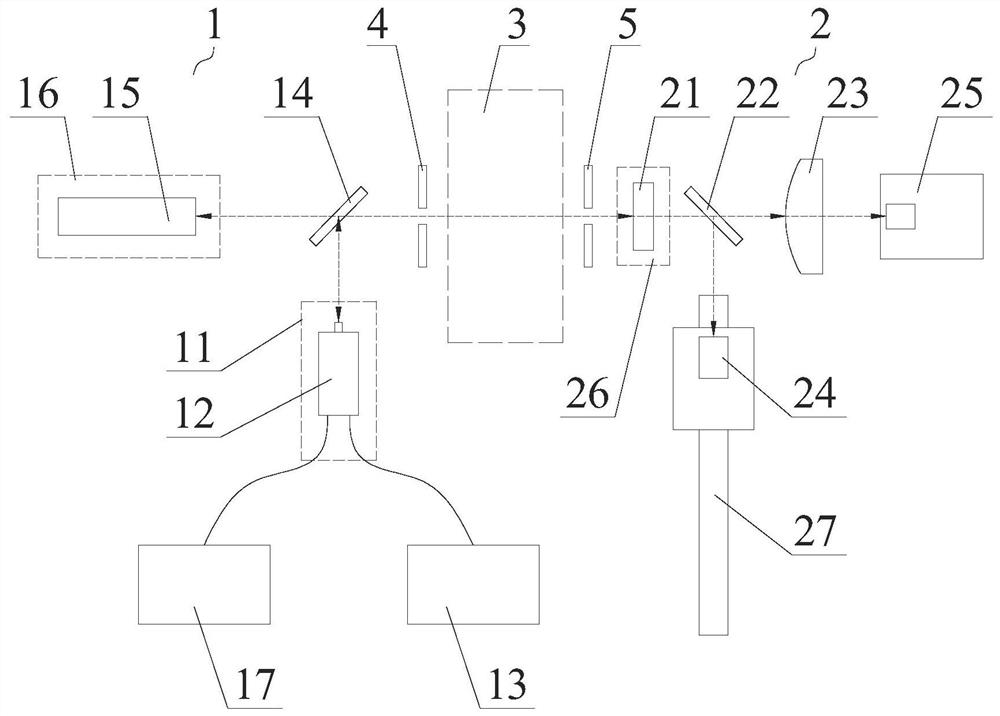

[0027] see figure 1 As shown, a high-precision optical optical path debugging device includes a light source module 1 and a receiving module 2. The light source module 1 is used to provide reference light used for debugging and a feedback signal during the debugging process. The receiving module 2 is used for The position and pointing angle of the light beam before and after the test optical path debugging; the light source module 1 includes an adjustment bracket 11, a fiber collimator 12, a reference light source 13 and a first beam splitter 14, and the fiber collimator 12 is installed on the optical five On the dimension adjustment bracket 11, the light output by the reference light source 13 is input into the optical module 3 to be debugged through the fiber collimator 12 and the first beam splitter 14, as a reference light source for optical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com