High-frequency inductor automatic back film machine and high-frequency inductor production process

A back film and inductor technology, applied in inductor/transformer/magnet manufacturing, circuits, electrical components, etc., can solve the problems of insufficient automation, difficult to guarantee the yield rate, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

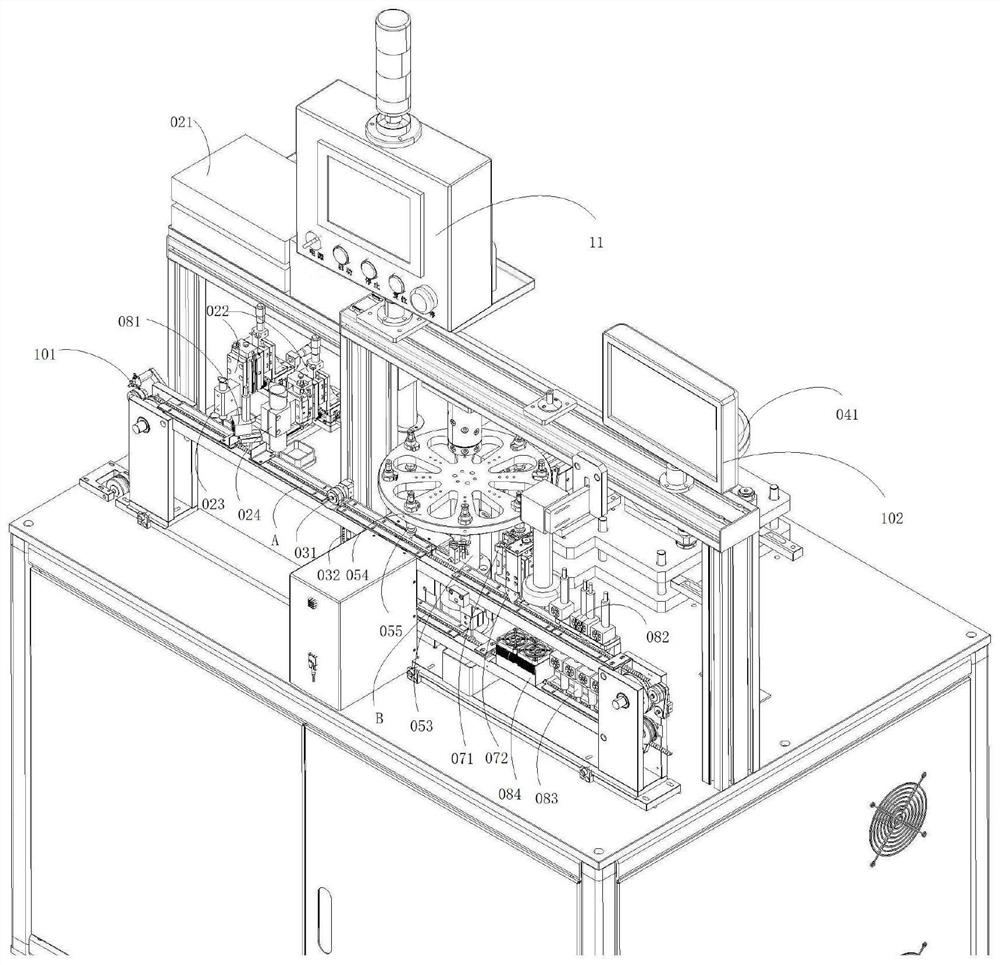

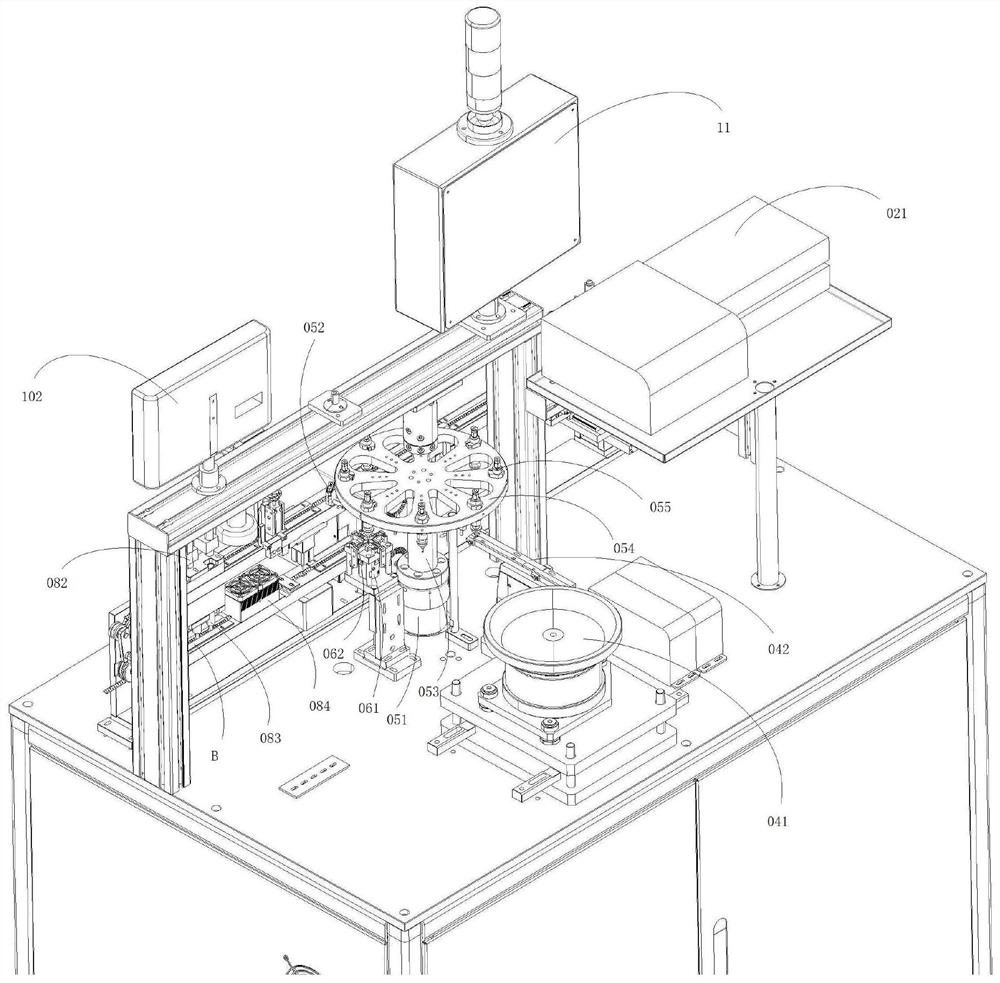

[0064] Please refer to figure 1 and figure 2 , a kind of high-frequency inductance automatic film backing machine involved in the present invention, comprises:

[0065] Film tape sending module 01, color point and glue dispensing module 02, film tape tensioning module 03, vibration discharge module 04, part pick and place module 05, part correction module 06, part leveling module 07, UV curing module 08, demoulding Receiving module 09, monitoring module 10 and control module 11;

[0066] The film tape sending module 01 includes a film tape sending motor, a film tape material roll, a film tape length control shaft, and a film tape guide wheel;

[0067] The color dispensing and dispensing module 02 includes a dispensing machine 021, a moving cylinder 022, and a color dispensing component 023 and a dispensing component 024 installed on the moving cylinder 022;

[0068] The film belt tensioning module 03 includes a tensioning guide wheel 031 and a tensioning spring 032;

[00...

Embodiment 2

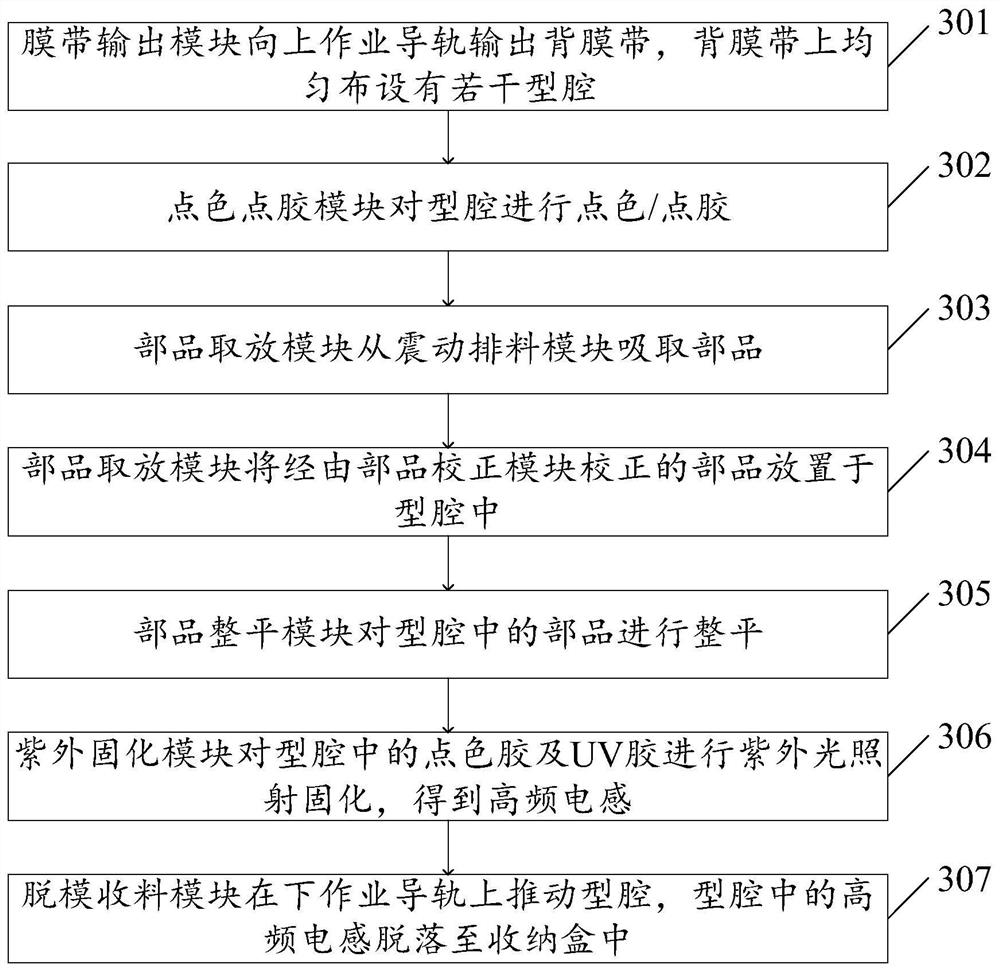

[0095] Please refer to image 3 , a high-frequency inductor production process involved in an embodiment of the present invention, comprising:

[0096] 301. The film tape output module outputs the back film tape to the upward working guide rail, and several mold cavities are evenly arranged on the back film tape;

[0097] 302. The color and glue dispensing module performs color / glue dispensing on the cavity;

[0098] 303. The parts pick-and-place module absorbs parts from the vibrating discharge module;

[0099] 304. The part pick-and-place module places the part calibrated by the part calibration module in the cavity;

[0100] 305. The part leveling module levels the parts in the cavity;

[0101] 306. The ultraviolet curing module irradiates and cures the dispensing glue and UV glue in the cavity with ultraviolet light to obtain high-frequency inductance;

[0102] 307. The demoulding and receiving module pushes the mold cavity on the lower working guide rail, and the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com