Motorcycle front shock absorber hollow aluminum cylinder sub-die-casting pouring machine

A front shock absorber and motorcycle technology, which is applied to casting equipment, mold handling equipment, manufacturing tools, etc., can solve the problems of low casting quality, high production cost, and large environmental pollution, and reduce pouring The effect of production cost, convenient and quick production adjustment, and simple follow-up processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention, so as to understand the concept of the present invention, the technical problems to be solved, the technical features constituting the technical solutions and the technologies brought about The effect has a further understanding.

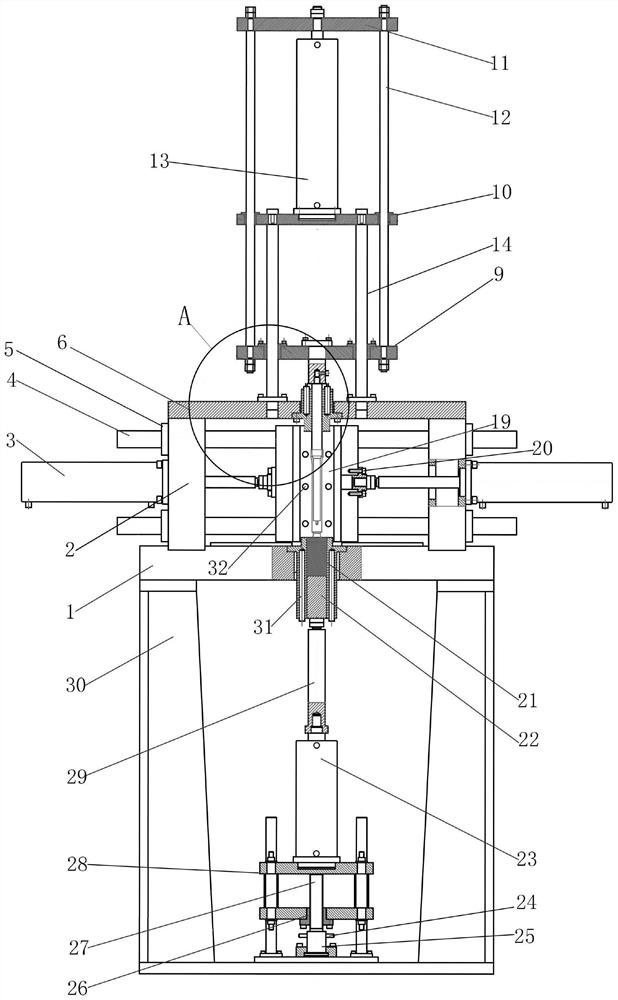

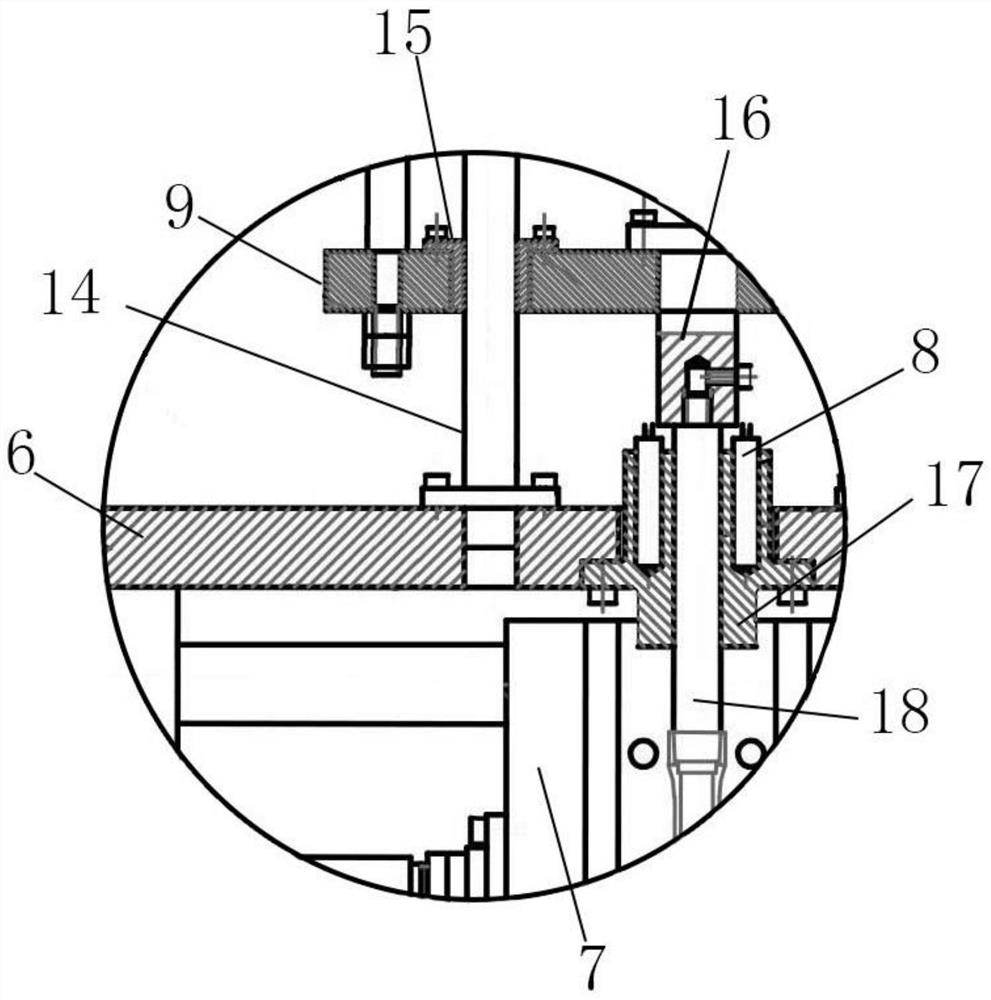

[0022] Such as figure 1 and figure 2As shown, a hollow aluminum cylinder sub-die-casting pouring machine for motorcycle front shock absorbers of the present invention includes a main structure composed of a base plate 1, a group of side support plates 2, a core sleeve mounting plate 6 and a steel plate welding bracket 30; The side support plate 2 is fixedly connected to the left and right ends of the upper surface of the base plate 1, the top end of the side support plate 2 is fixedly connected to the two ends of the lower surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com