Modeling method and optimization method for the whole process of hydrometallurgy based on interval numbers

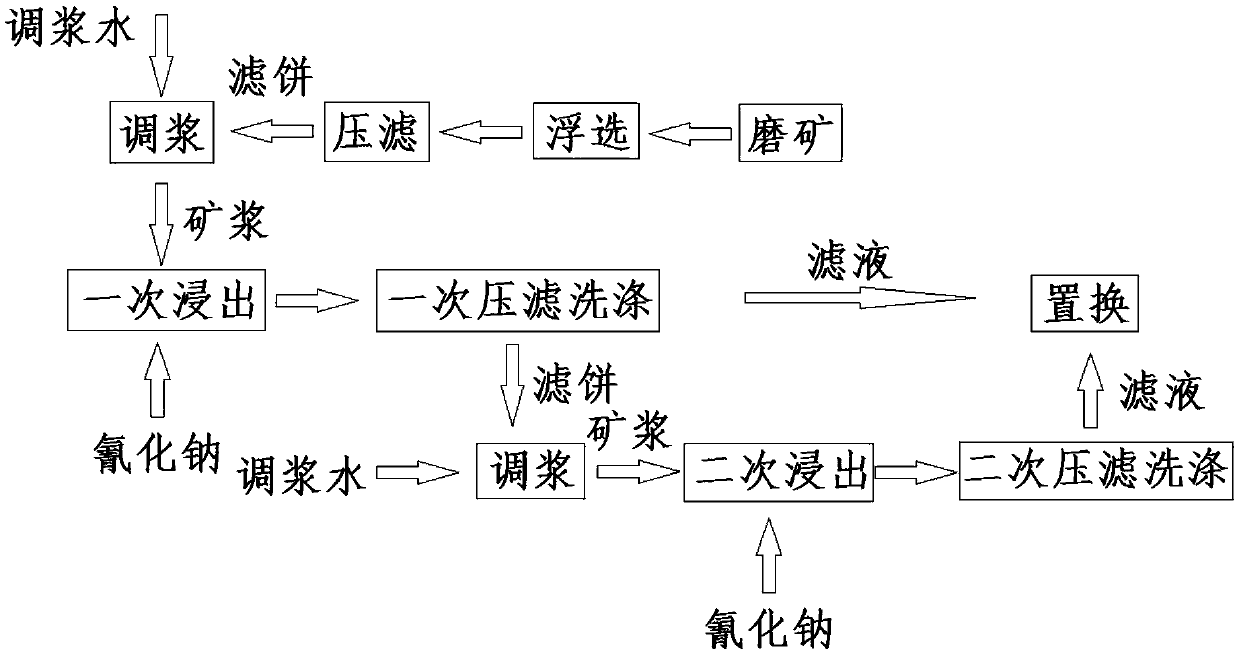

A hydrometallurgy, full-process technology, applied in the field of metallurgy, can solve the problems of large-scale hydrometallurgy process, many processes and variables, and complex optimization problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

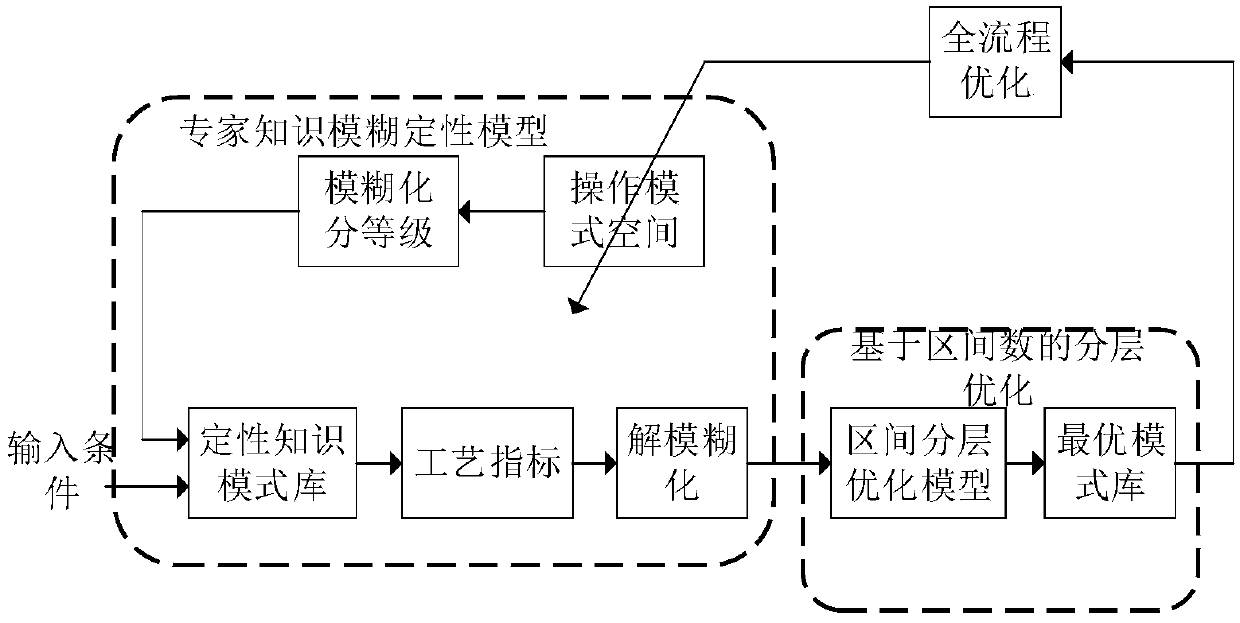

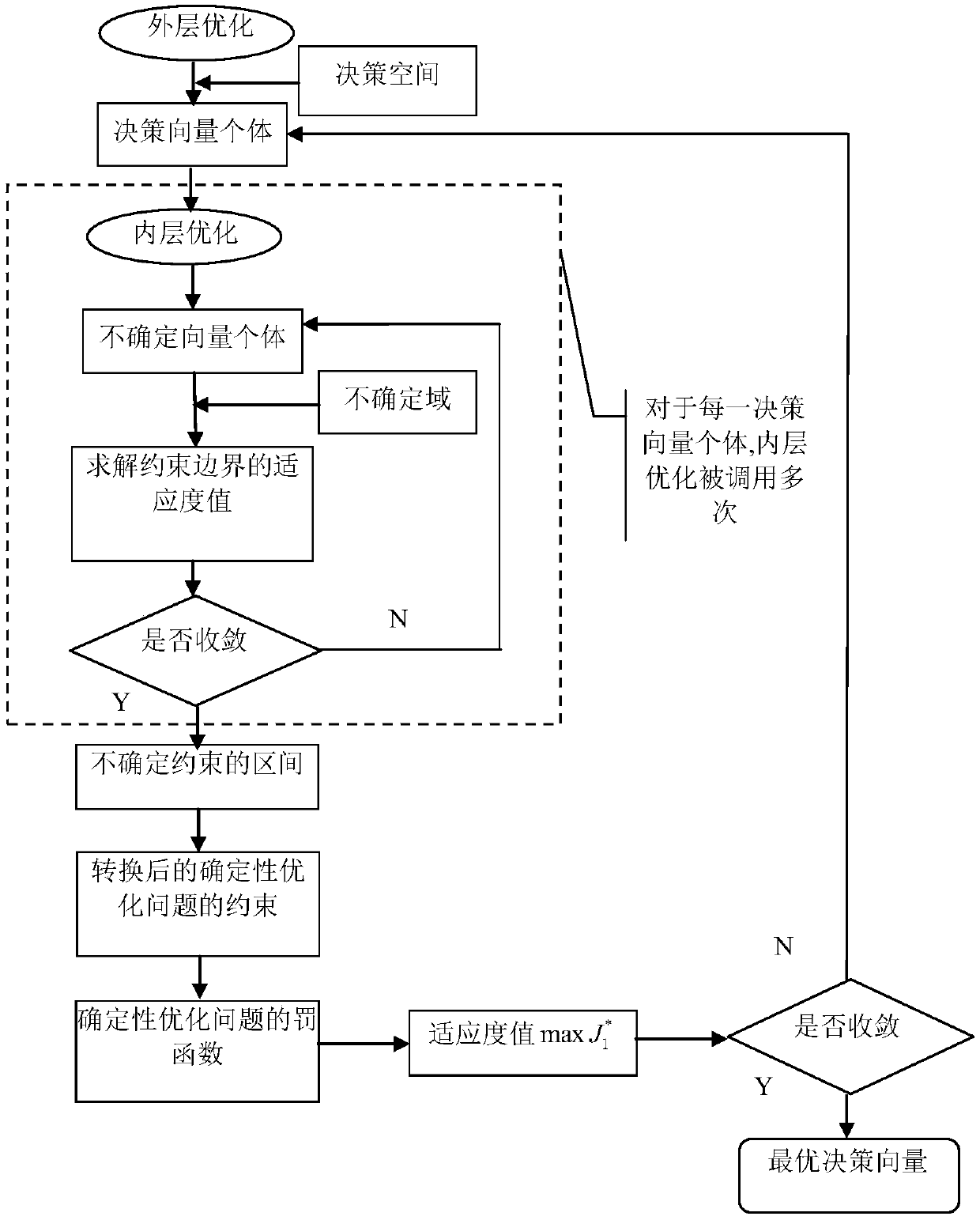

[0116] combine Figure 2 to Figure 5 As shown, the hydrometallurgy whole-process modeling method based on the interval number in this embodiment includes:

[0117] Step S1, according to the input variables, output variables and operating variables in the historical data in the preset time period, the operation mode library of the upstream sub-process in the hydrometallurgical process is established, and the operation mode library includes: input variables, output variables and operation variables The mapping relationship between variables.

[0118] In this embodiment, the input variables include: ore draw ΔM with at least five levels;

[0119] Output variables include: pulp concentration C with at least five grades w ;

[0120] The operational variables include: conditioning water Δq with at least seven levels.

[0121] The quality indicators of each process include: primary leaching rate, secondary leaching rate and replacement rate.

[0122] In this embodiment, in order...

Embodiment 2

[0204] This embodiment provides a method for optimizing the entire process of hydrometallurgy. The devices used in the realization of the method include a hydrometallurgical process modeling and optimization system, a host computer, PLC, and on-site sensing and transmission parts. Among them, the on-site sensing and transmission part includes detection instruments such as concentration, pressure and flow. The detection instrument is installed on site in the hydrometallurgical process, and the detection instrument sends the collected signal to the PLC through the Profibus-DP bus, and the PLC regularly transmits the collected signal to the host computer through Ethernet, and the host computer transmits the received data to the hydrometallurgy process Model and optimize the system, optimize the production process, and provide guidance and suggestions for production operations.

[0205] The functions of each part of the device of the present invention:

[0206] ① On-site sensing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com