Method for producing low b-value 4A zeolite

A production method and technology of zeolite, which are applied in the directions of A-type crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve problems such as low yield, and achieve the effects of short process flow, improved particle size, and easy washing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

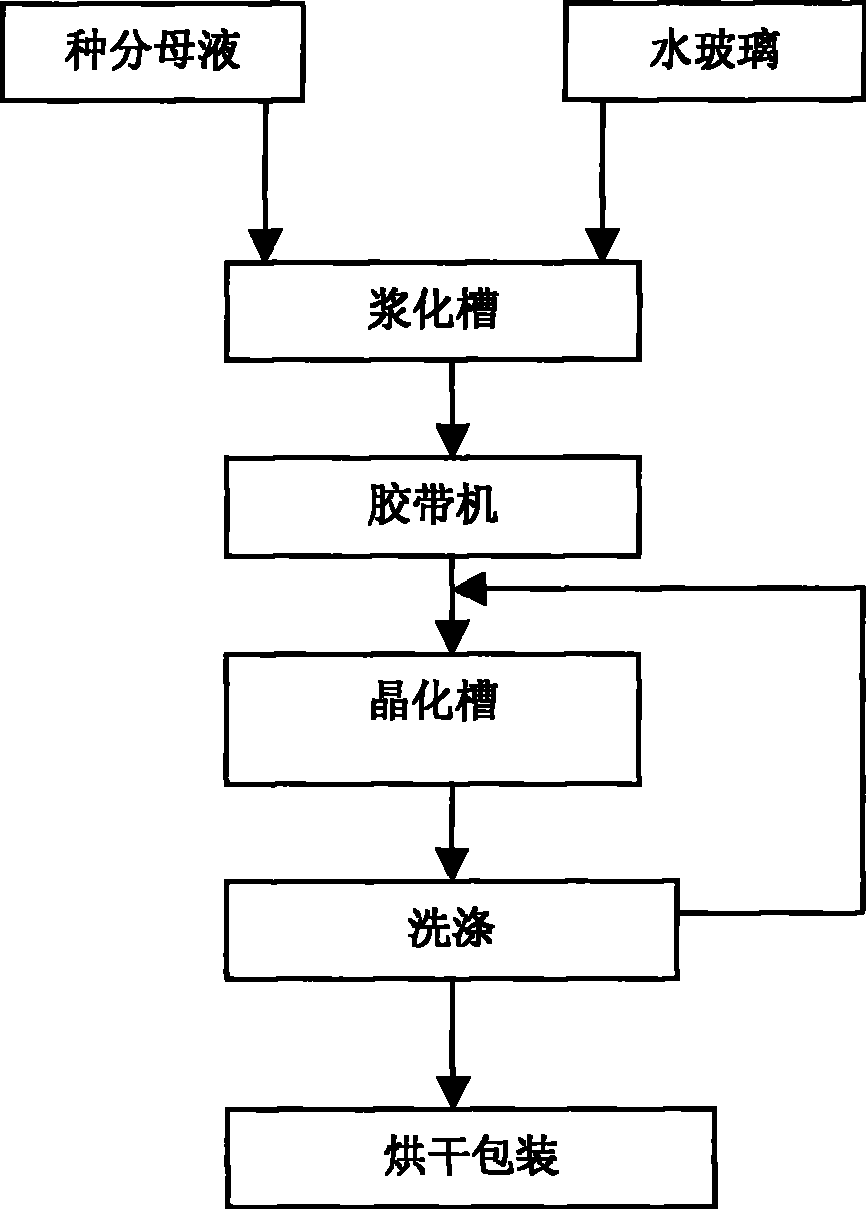

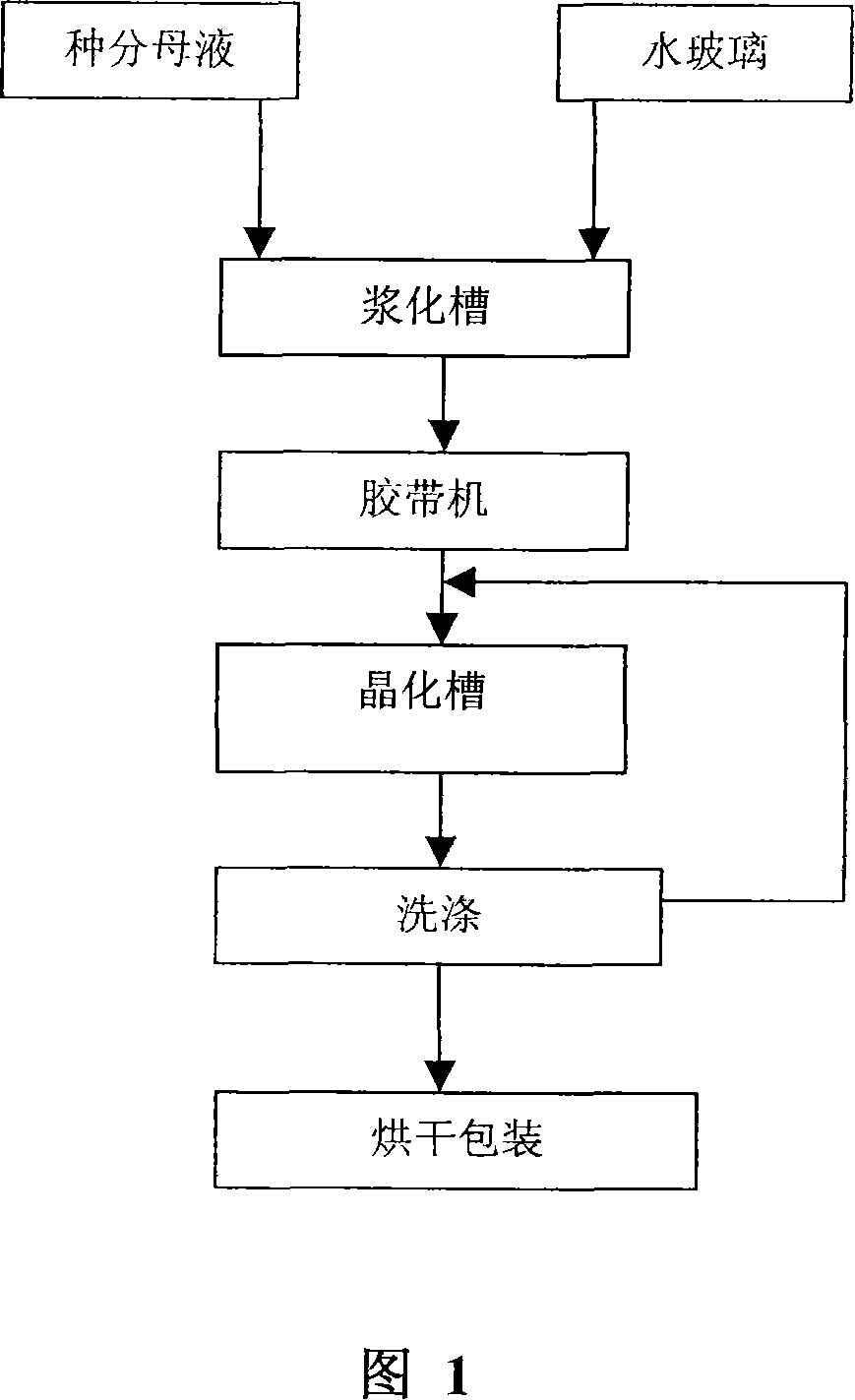

Method used

Image

Examples

Embodiment 1

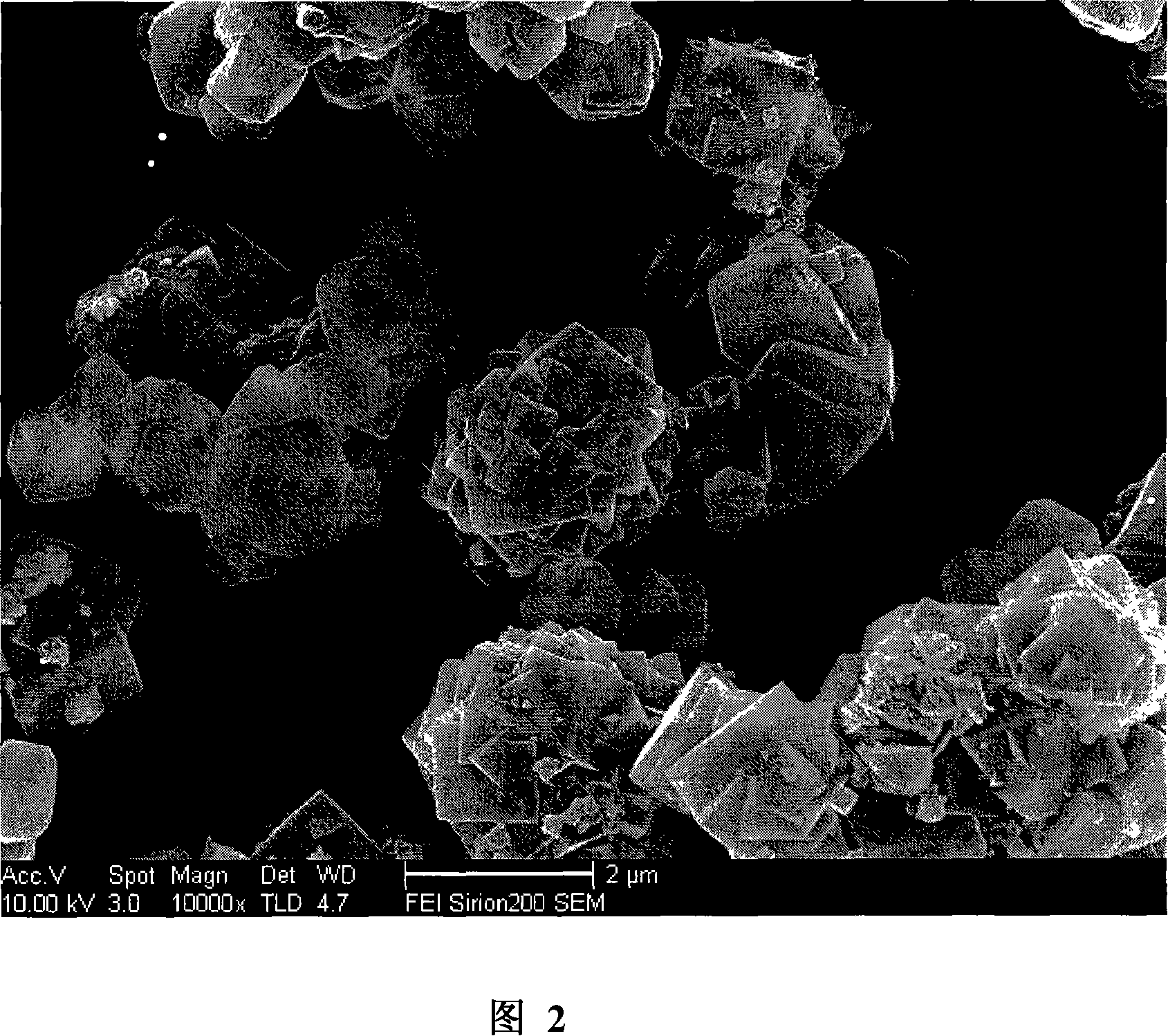

[0024] Separation of mother liquor Al in Bayer process 2 o 3 When the concentration is 55g / L, with SiO 2 Continuous co-current synthesis of water glass with a weight concentration of 15%. Before the synthesis, keep the original temperature of the Bayer method seed separation mother liquor at 5-60°C, the water glass temperature is 25-30°C, the slurry ratio is S / A=1.6, and when the stirring speed is 45 rpm, the two The solution is continuously injected into the pulping tank, from the pulping tank into the buffer tank, and then into the belt machine for separation, and then beaten with lotion. The adjusted alkalinity NT is 70g / L. Crystallize at 65°C for 4 hours, crystallize at 75°C for 1 hour, and obtain the product after separation, washing and drying. The results are shown in the table below:

[0025] calcium exchange

[0026] In the table, L, a, and b are representative values of object chromaticity, L represents the light-dark axis, a represents the red-green ...

Embodiment 2

[0028] Separation of mother liquor Al in Bayer process 2 o 3 When the concentration is 55g / L, with SiO 2 Continuous co-current synthesis of water glass with a weight concentration of 25%. Before the synthesis, keep the original temperature of the Bayer process seed separation mother liquor at 55-60°C, the water glass temperature is 25-30°C, the slurry ratio is S / A=1.7, and when the stirring speed is 45 rpm, the two The solution is continuously injected into the pulping tank, from the pulping tank into the buffer tank, and then into the belt machine for separation, and then beaten with lotion. The adjusted alkalinity NT is 90g / L. Crystallize at 65°C for 5 hours, crystallize at 75°C for 2 hours, and obtain the product after separation, washing and drying. The results are shown in the table below:

[0029]

Embodiment 3

[0031] Separation of mother liquor Al in Bayer process 2 o 3 When the concentration is 75g / L, with SiO 2 Continuous co-current synthesis of water glass with a weight concentration of 20%. Before the synthesis, keep the original temperature of the Bayer method seed separation mother liquor at 55-60°C, the water glass temperature is 25-30°C, the slurry ratio is S / A=1.80, and when the stirring speed is 45 rpm, the two The solution is continuously injected into the pulping tank, from the pulping tank into the buffer tank, and then into the belt machine for separation, and then beaten with lotion. The adjusted alkalinity NT is 100g / L. Crystallize at 55°C for 5 hours, crystallize at 75°C for 3 hours, and obtain the product after separation, washing and drying. The results are shown in the table below:

[0032] calcium exchange

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com