Power transmission line strain clamp convenient for robot maintenance

A technology of transmission lines and tension clamps, which is applied in the direction of overhead lines/cable equipment, adjusting/maintaining mechanical tension, etc., and can solve the problem of difficult precise control and detection of fastening pre-tightening force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

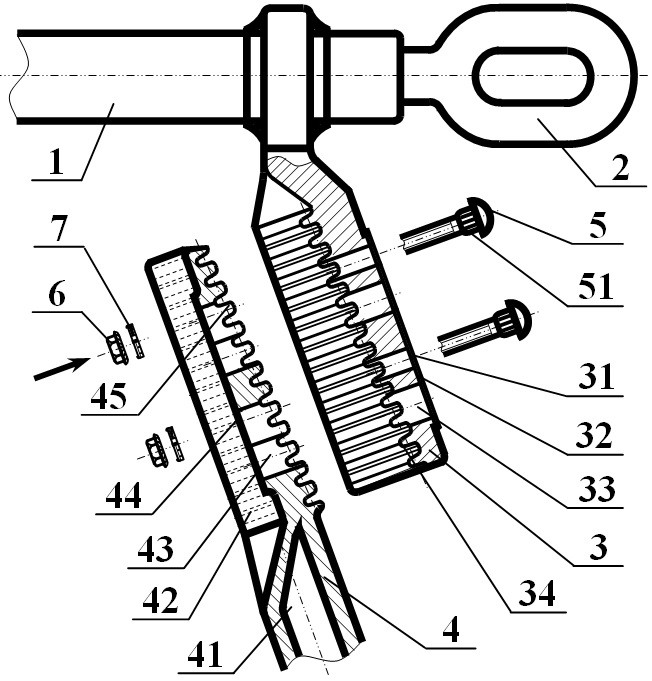

[0084] figure 1 It is a schematic diagram of the overall structure of the strain clamp, including aluminum tube 1, steel anchor 2, drainage plate 3, drainage clamp 4, pressure riveting bolt 5, flange nut 6 and marking washer 7. Both the aluminum tube 1 and the steel anchor 2 are manufactured using the materials, structures and processing techniques of the known aluminum tube and steel anchor of the strain clamp.

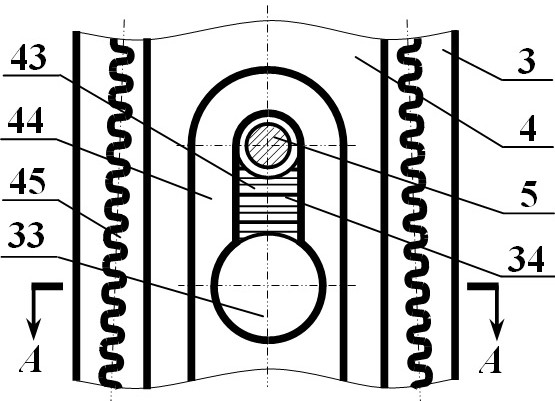

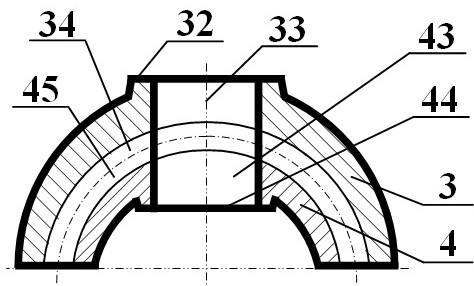

[0085] figure 2 For the drainage plate 3 and the drainage clip 4 in the figure 1 Partial view in the direction of the arrow in the middle; image 3 for figure 2 middle A — A The sectional view shown. The drainage plate 3 is a vertically inclined and symmetrical straight curved inner tooth plate with bolt holes 31, outer bosses 32, operating holes 33 and inner teeth 34, preferably known aluminum plate profiles a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com