Nutritional chocolate and production equipment thereof

A technology for producing equipment and chocolate, applied in the field of chocolate, can solve the problems of cumbersome production steps, low nutrient content, and the proportion of production equipment in chocolate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

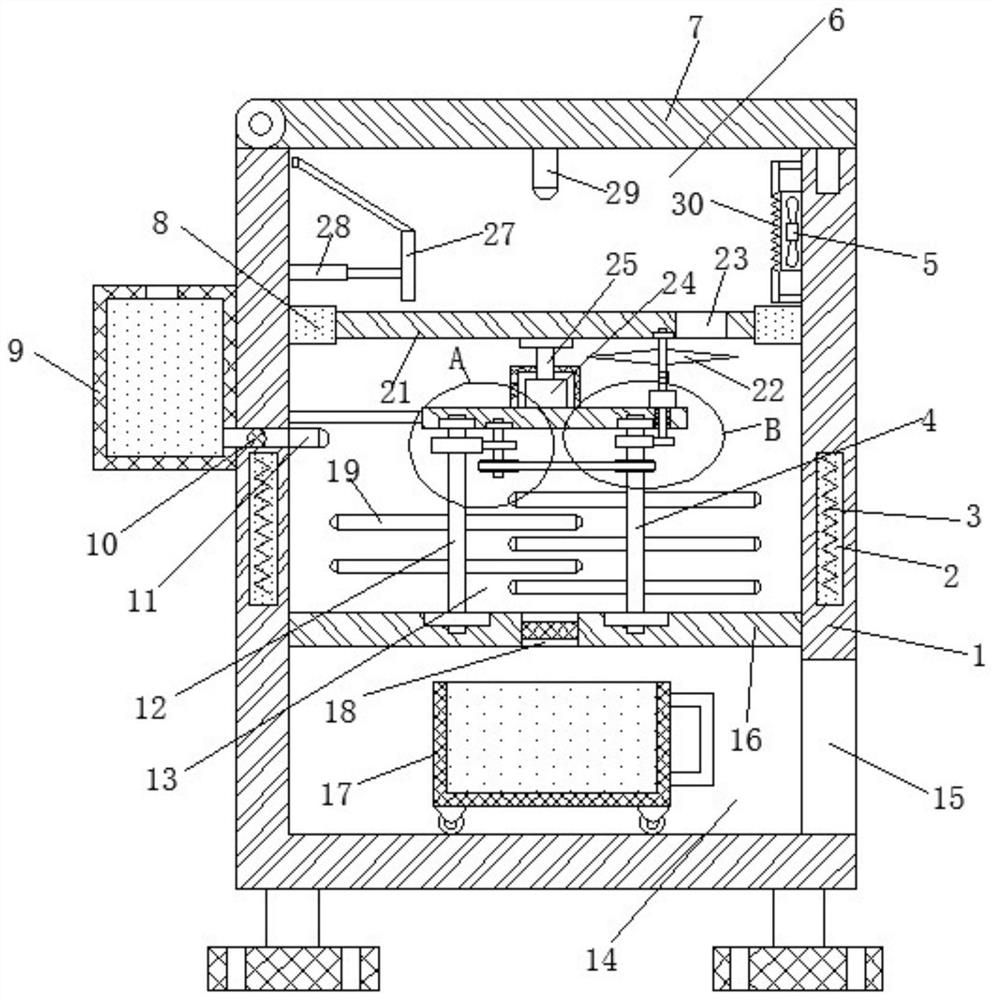

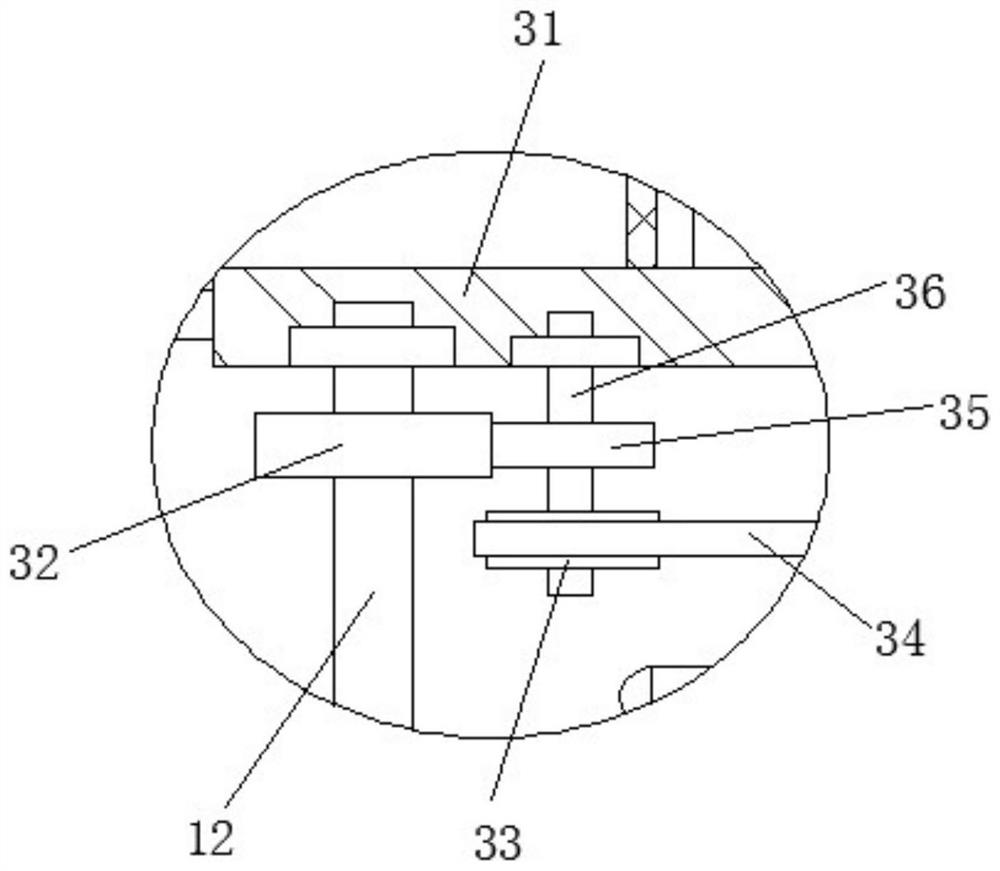

Embodiment 1

[0027] A nutritious chocolate, comprising the following raw materials in parts by weight: 3 parts of white granulated sugar, 4 parts of skim milk powder, 18 parts of cocoa butter, 6 parts of milk fat, 1 part of calcium tablet, 1 part of vitamin C, 55 parts of cocoa mass, food flavoring 4 parts, 1 part lactose, 7 parts milk, 2 parts raisins. Heat and melt 18 parts of cocoa butter, 6 parts of milk fat and 55 parts of cocoa mass, then add 3 parts of white sugar, 1 part of calcium tablet, 1 part of vitamin C, 4 parts of flavoring, 1 part of lactose, 7 parts of milk and 2 Raisins, then air-dried to remove moisture, vibrate, stir and keep warm to obtain nutritious chocolate raw materials. The nutritious chocolate raw materials are hardened, demoulded and packaged to obtain nutritious chocolate. Compared with traditional chocolate, the nutritional elements of the obtained nutritious chocolate increase: 6% Calcium content, 4% vitamin C content, 3% lactose content, one molecule of lact...

Embodiment 2

[0029] A nutritious chocolate, comprising the following raw materials in parts by weight: 4 parts of white granulated sugar, 6 parts of skim milk powder, 20 parts of cocoa butter, 8 parts of milk fat, 2 parts of calcium tablets, 2 parts of vitamin C, 65 parts of cocoa mass, food flavoring 5 parts, lactose 5 parts, milk 10 parts, raisins 4 parts. Heat and melt 20 parts of cocoa butter, 8 parts of milk fat and 65 parts of cocoa mass, then add 4 parts of white sugar, 2 parts of calcium tablets, 2 parts of vitamin C, 5 parts of flavoring, 5 parts of lactose, 10 parts of milk and 4 parts of milk. raisins, and then air-dried to remove moisture, vibrate, stir and keep warm to obtain nutritious chocolate raw materials. The nutritious chocolate raw materials are hardened, demoulded and packaged to obtain nutritious chocolate. The nutritious chocolate obtained: the calcium content is 8%, vitamin C The content is 6%, and the lactose content is 5%. Compared with the nutritional chocolate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com