A kind of deesterification distillation process of aged naphthenic acid extractant

A naphthenic acid and extractant technology, applied in the field of deesterification distillation process, can solve the problems of difficult adjustment, complicated control and high energy consumption, and achieve the effects of recovering the extraction function, high conversion rate and eliminating emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

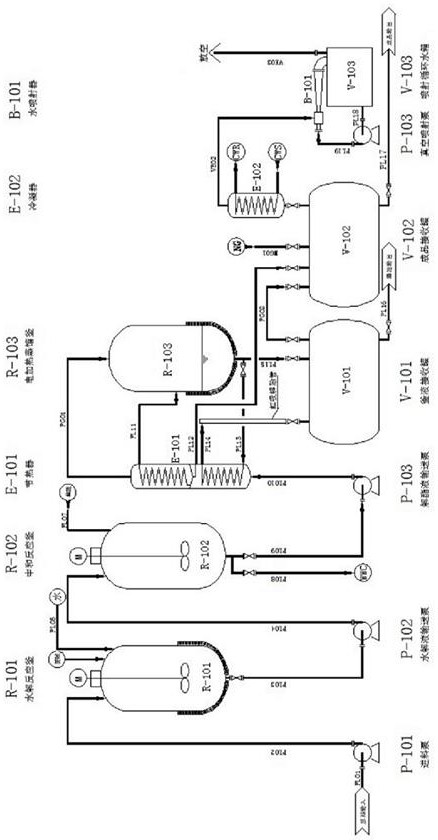

[0029] see figure 1 , a de-esterification distillation process of an aging naphthenic acid extractant, comprising the following steps:

[0030] S1, hydrolysis: take 1500L of aging naphthenic acid extractant and place it in a 2000L electric heating reactor, turn on the stirrer, rotate at 80 rpm, heat to 80°C, add 52 kg of granular sodium hydroxide, add 11 L of deionized water , and the reaction was stirred for 4 hours;

[0031] S2, neutralization: complete the hydrolyzate of step 1, cool to 40 ℃, keep the previous stirring state, slowly drip 217L of hydrochloric acid with a concentration of 6mol / L, the reaction time is 30 minutes, stop stirring after the reaction, and let stand for 30 minutes , the still liquid is divided into an organic phase and an aqueous phase, and the deesterification liquid of the aging naphthenic acid extractant is obtained after cutting out the aqueous phase;

[0032] S3, underpressure distillation: the deesterification liquid that completes step 2 en...

Embodiment 2

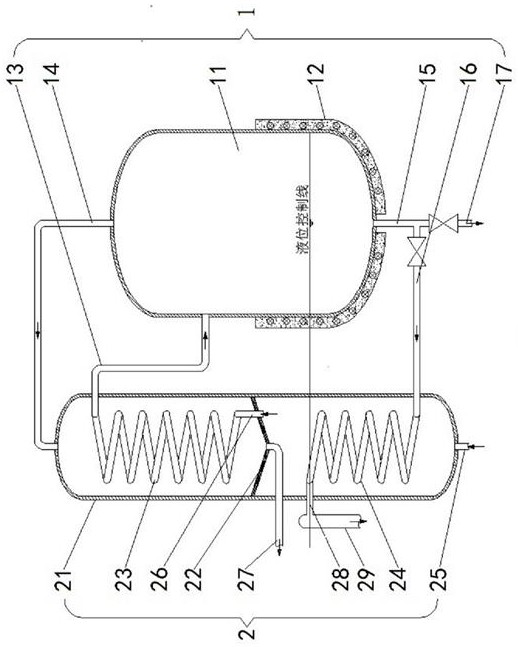

[0039] see figure 2, a distillation device suitable for the deesterification distillation process of aging naphthenic acid extractant, comprising an electric heating still 1, the electric heating still 1 comprises a still 11, the bottom of the still 11 is covered with an electric heating jacket 12, and the still One side of 11 is connected with a liquid communication pipe 13, the top of the still 11 is connected with a distillation vapor communication pipe 14, the bottom of the still 11 is provided with a still liquid outlet 15, and one side of the still liquid outlet 15 is connected with The still liquid communication pipe 16, the bottom of the still liquid outlet 15 is connected with the still liquid venting pipe 17, the electric heating jacket 12 is energized for heating and distillation, the de-esterification liquid inside 11, the vapor evaporated in the de-esterifying liquid passes through the distillation steam. The body communication pipe 14 enters the upper space of t...

Embodiment 3

[0041] see figure 2 , a distillation device suitable for the deesterification and distillation process of the aging naphthenic acid extractant, comprising an electric heating still 1 and an economizer 2, the economizer 2 is fixedly connected to one side of the electric heating still 1, and the The heater 2 includes an economizer housing 21, the top of the economizer housing 21 is connected with a distillation gas communication pipe 14, the inner wall of the economizer housing 21 is welded with a conical partition 22, and the economizer housing 21 A serpentine condensing heat exchange coil 23 is fixedly connected to the inner top of the heat exchanger, a liquid communication pipe 13 is connected to the top of the serpentine condensation heat exchange coil 23, and a serpentine cooling heat exchange plate is fixedly connected to the inner bottom of the economizer shell 21 Tube 24, the bottom of the serpentine cooling heat exchange coil 24 is connected with the still liquid commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com