A liquid discharge control device and method for a supergravity centrifugal model

A centrifugal model and emission control technology, which is applied in the direction of centrifuges, comprehensive factory control, centrifuges with rotating drums, etc., can solve whether the success of the test is full of variables, intervene and adjust control variables, and increase the difficulty of model making and other issues to achieve the effects of saving analysis costs, timely feedback and changes, and simple and easy control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

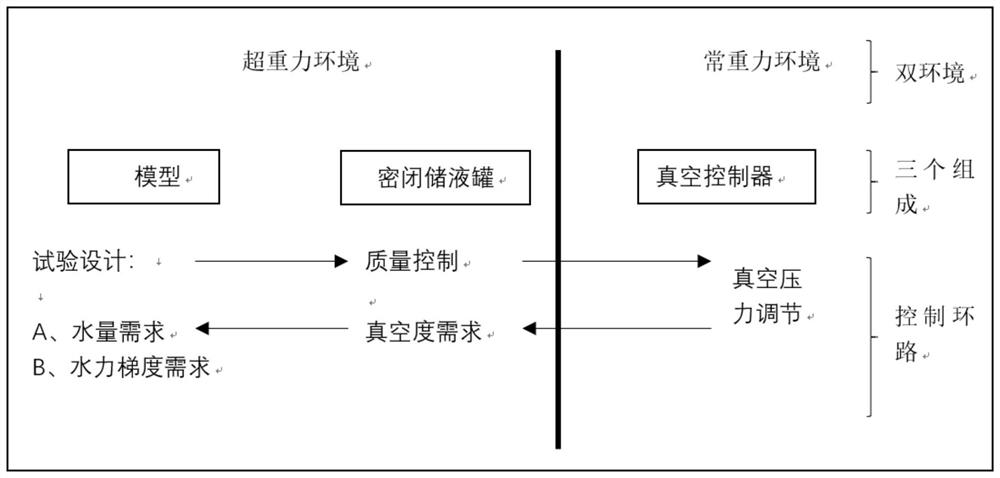

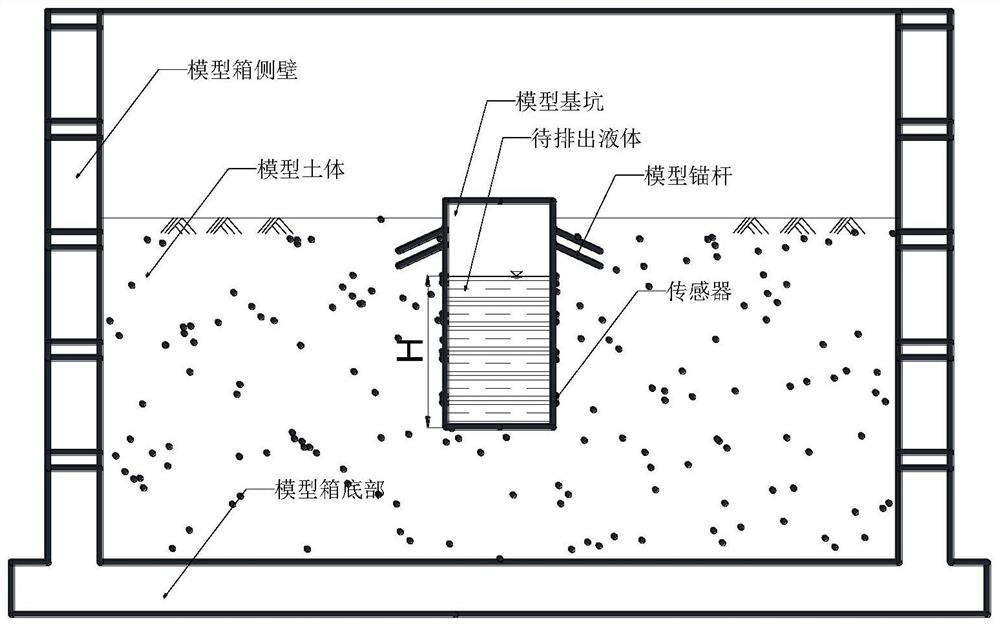

[0060] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

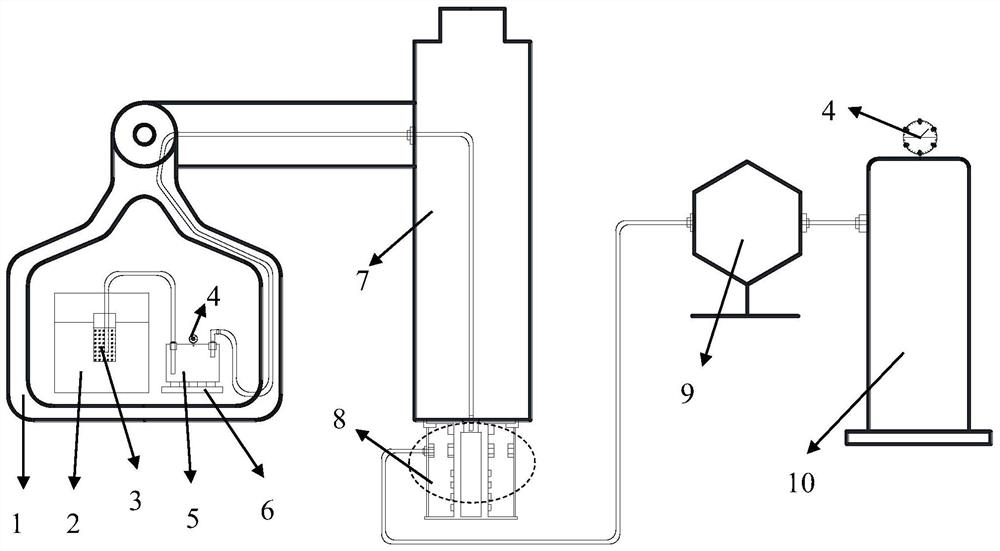

[0064] The trachea pipeline is connected to the liquid ring device 8 after extending from the test end hanging basket 1 through the rotating arm and the rotating shaft of the hypergravity centrifuge.

[0066] There is a vacuum pump in the vacuum regulation system 10, and the vacuum pump is used for vacuuming operation. Vacuum regulation system 10 jobs

[0070] Z

[0073] Z

[0078] is to use manual adjustment to pre-adjust to an empirical value, and then enter the system automatic adjustment link, because I

[0081] Specifically, the liquid discharge rate ΔM* / Δt can be compared with the set liquid quality control parameter Z

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com