Supergravity centrifugal model liquid discharge control device and method

A centrifugal model, emission control technology, used in centrifuges, full plant control, centrifuges with rotating drums, etc., can solve problems such as low efficiency, inability to effectively guide, and inability to give timely feedback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

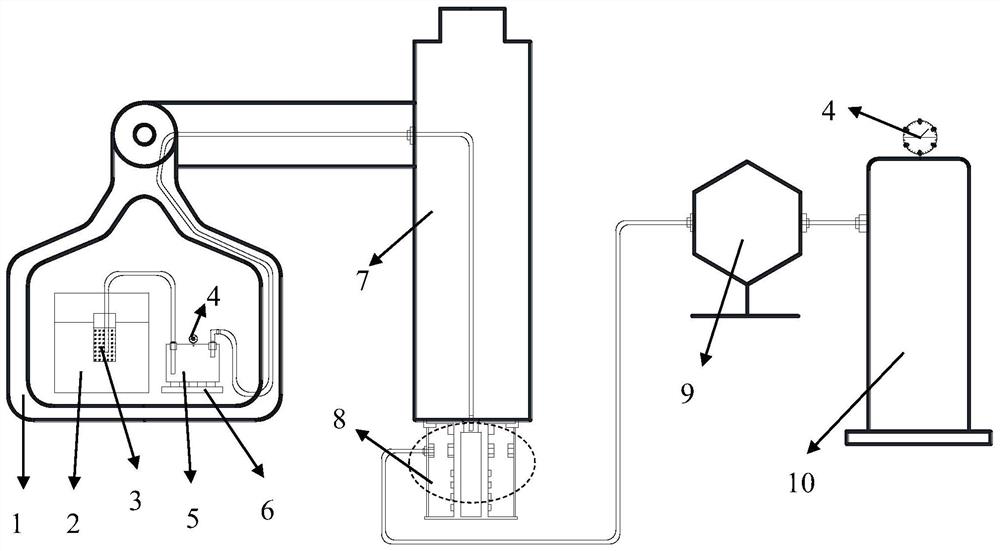

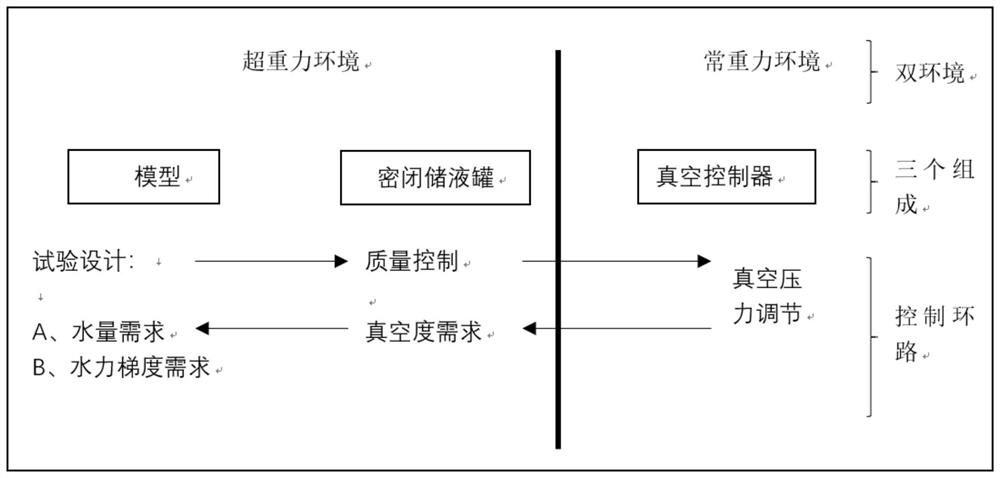

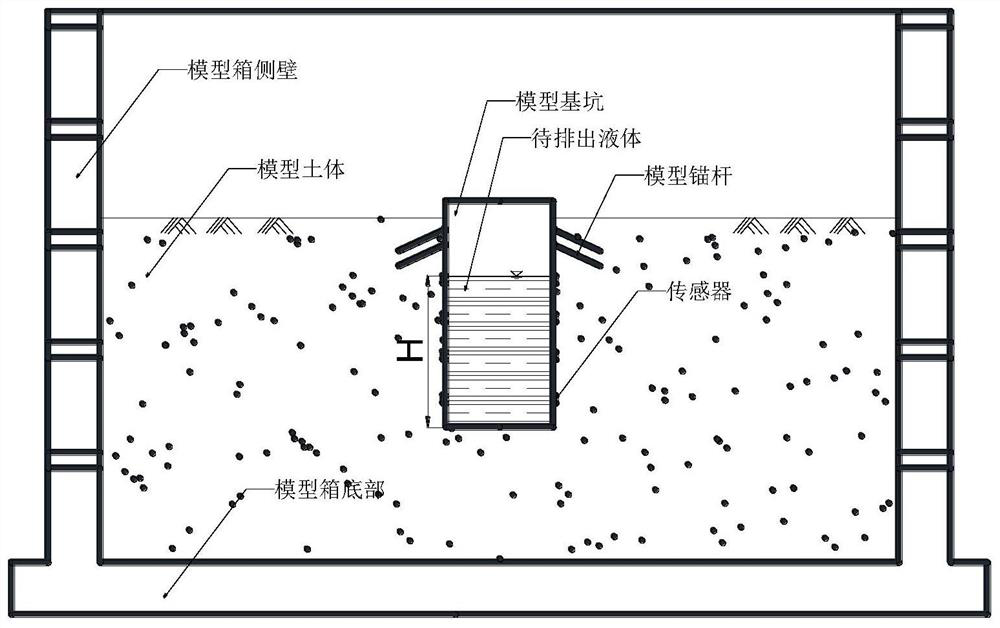

[0061] Such as figure 1 As shown, the supergravity centrifuge includes a supergravity centrifuge main body 7 and a test end hanging basket 1, a centrifugal model 2 is placed in the test end hanging basket 1, and the bottom of the centrifugal model 2 is fixed on the inner bottom surface of the test end hanging basket 1; Liquid area 3, pressure gauge 4, closed liquid storage tank 5, precision electronic scale 6, liquid ring device 8, proportional regulating valve 9 and vacuum regulating system 10; proportional regulating valve 9 and vacuum regulating system 10 are placed in a constant gravity environment, The rest of the devices were placed in a hypergravity environment.

[0062] The liquid area 3 to be drained is placed in the centrifugal model 2, the precision electronic scale 6 and the closed liquid storage tank 5 are placed in the test end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com