Horizontal well injection repairing method and device for shallow organic pollution site

A technology of organic pollution and remediation methods, applied in the restoration of polluted soil, etc., can solve the problems of waste of chemicals, inaccessibility of contaminated areas, large amount of pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

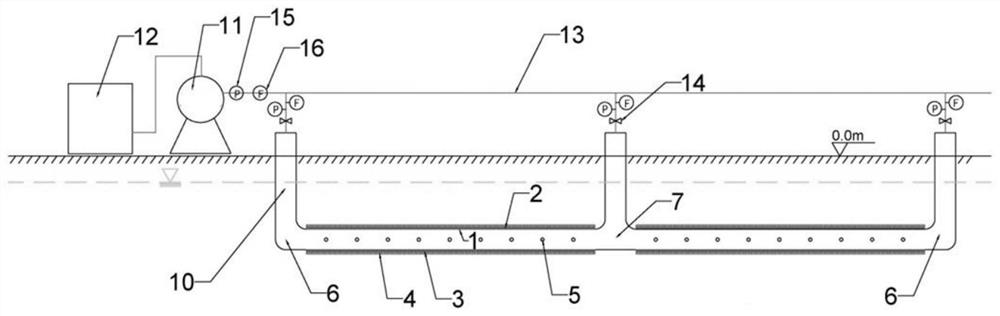

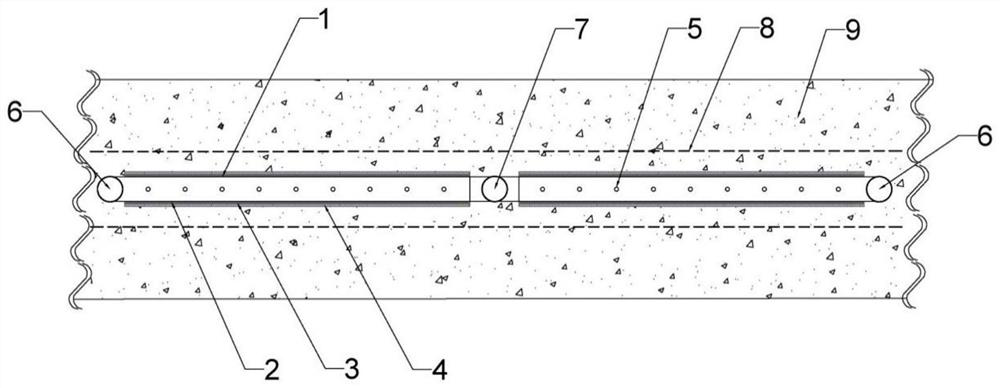

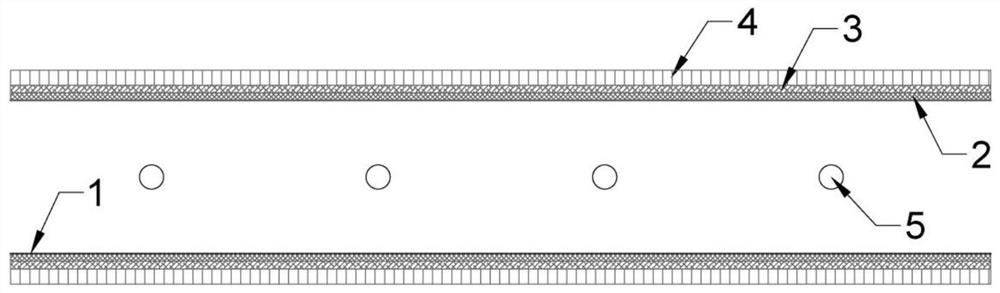

Embodiment 1

[0041] The shape of the organic pollution area in a polluted site is as follows: the longest length is 242m, and the widest width is 24m (such as Figure 5 shown). The site restoration area is about 4676m2 2 , the soil pollutants are benzo(a)anthracene and nitrobenzene, the maximum concentrations are 49.2mg / kg and 224.5mg / kg respectively, the pollution depth is 0-4m, and the remediation target values are 5.5mg / kg and 34mg / kg respectively; The groundwater pollutants are petroleum hydrocarbons, the maximum pollution concentration distribution is 3.2mg / L, the remediation targets are 0.6mg / L, the pollution depth is 5.5m, and the water level is buried at 1.7m. The first layer of site soil is miscellaneous fill soil layer with a thickness of 0.8-2m, the second layer of silty clay layer with a thickness of 3-4.5m, and the third layer is a clay layer, and the drill holes have not been drilled through.

[0042] The process of the present invention is used for repairing.

[0043] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com