Biological food-based sealed constant-temperature fermentation tank for broomcorn wine brewing

A constant temperature fermentation and fermenter technology, applied in the preparation of alcoholic beverages, etc., can solve the problems that yeast cannot consume sorghum oxygen more fully and quickly, the degree of saccharification is low, and the sorghum fermentation is affected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

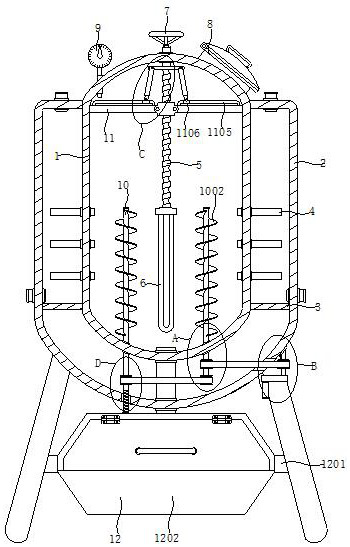

[0027] see Figure 1-7, the present invention provides a technical solution: a sealed constant temperature fermenter for sorghum wine making based on biological food, comprising a fermenter 1, the outer wall of the fermenter 1 is fixedly covered with an insulating layer 2, the inner wall of the insulating layer 2 and an annular partition An annular partition 3 is fixedly installed between the outer walls of the fermenter 1, a heat conduction rod 4 is fixedly connected to the outer wall of the fermenter 1 and one end of the heat conduction rod 4 extends to the inside of the fermenter 1, and the inner top of the fermenter 1 is rotated and installed with a first screw thread Rod 5 and one end of the first threaded rod 5 runs through the fermenter 1 and is fixedly connected with a rotating handle 7, the other end of the first threaded rod 5 is fixedly connected with a heating rod 6, and the top outer surface of the fermenter 1 is fixedly installed with a feed hopper 8 and communic...

Embodiment 2

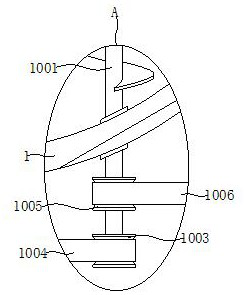

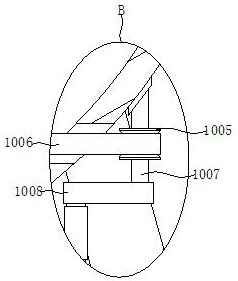

[0029] see Figure 1-7 , On the basis of Embodiment 1, the stirring mechanism 10 includes a rotating rod 1001, a helical blade 1002, a first pulley 1003, a first belt 1004, a second pulley 1005, a second belt 1006, a short rotating rod 1007 and a hand handle 1008 Two groups of rotating rods 1001 are mounted on the inner bottom of the fermenter 1 for rotation. The two groups of rotating rods 1001 are fixedly provided with helical blades 1002. One end of the two groups of rotating rods 1001 runs through the fermenter 1 and is fixedly connected with the first pulley. 1003, the two sets of first pulleys 1003 are equipped with first belts 1004, the two sets of first pulleys 1003 are connected through the transmission of the first belts 1004, the outer surface of the bottom of the fermenter 1 is rotated and installed with a short rotating rod 1007, the short rotating rod One end of 1007 is fixedly connected with a hand handle 1008, and the short rotating rod 1007 and one group of ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com