Preparation method of novel formaldehyde-free high-strength ecological environment-protecting flaky solid wood structure plate

A high-strength, structural panel technology, applied in the jointing of wooden veneers, flat products, manufacturing tools, etc., can solve the problems of large specific surface area of shavings, large shavings on the surface of the board, and variability of the board, so as to prevent fire hazards, Improved heat utilization rate and low drying temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

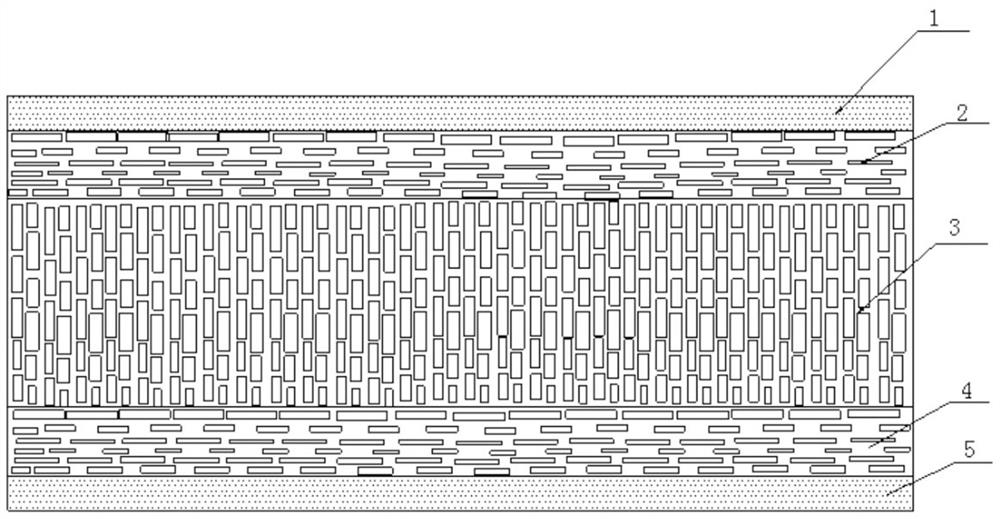

[0049] Such as figure 1 A new type of formaldehyde-free high-strength eco-friendly sheet-like solid wood structural board is shown, including a lower surface layer 5, a lower shaving layer 4, a core layer 3, an upper shaving layer 2, and an upper surface layer 1 arranged sequentially from bottom to top. .

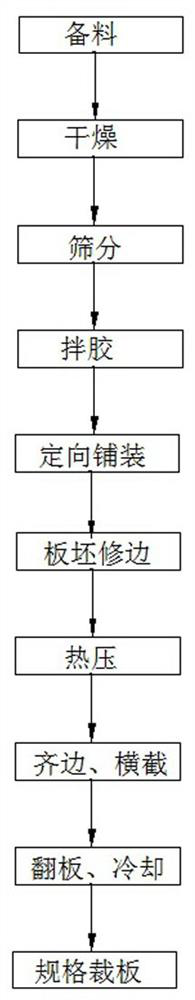

[0050] The preparation method of the above-mentioned novel eco-environmental protection type sheet-like solid wood structural board with no formaldehyde and high strength, such as figure 2 shown, including the following steps:

[0051] S1. Material preparation: Obtain narrow, long and thin shavings with a length of 90-130 mm, a width of 10-30 mm, and a thickness of 0.3-0.9 mm through a long wood flaking machine, and send them to the wet shaving silo for storage. The wet shaving silo It is a rectangular structure wet shaving silo, the shape of the shavings in the silo will not be damaged, which ensures the integrity of the shavings; and the upper end of the silo is fed, a...

Embodiment 2

[0075] The difference between this embodiment and embodiment 1 is:

[0076] In this embodiment, the mass ratio of the isocyanate adhesive to the VA curing agent is 6:1, the spraying amount of the surface wood shavings is in the range of 4.0 kg / m3, and the core wood shavings are mixed The range of spraying amount of glue is 5.1 kg / m3, and the range of spraying amount of glue mixed with fine shavings is 6.5 kg / m3.

[0077] In this embodiment, after continuous hot pressing, unqualified products are removed by bubble detection method, so as to obtain qualified sheet-shaped solid wood structural boards.

[0078] In this embodiment, the thickness of the continuous slab is detected by the thickness detection device, and the online feedback is given to the directional mechanical paving machine, so as to automatically adjust the uniformity of the thickness of the slab.

[0079] Others are with embodiment 1.

Embodiment 3

[0081] The difference between this embodiment and embodiment 2 is:

[0082] In this embodiment, the mass ratio of the isocyanate adhesive to the VA curing agent is 1:1, the spraying amount of the surface wood shavings is in the range of 4.6 kg / m3, and the core wood shavings are mixed The range of spraying amount of glue is 4.5 kg / m3, and the range of spraying amount of glue mixed with fine shavings is 6.6 kg / m3.

[0083] Others are with embodiment 2.

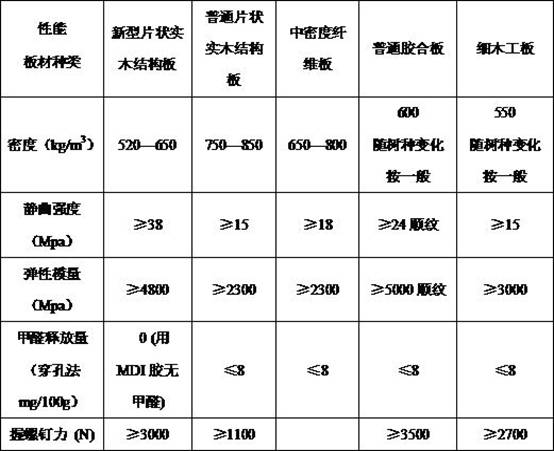

[0084] Compared with the existing several boards of the new sheet-like solid wood structural board prepared by the embodiment, the parameter values are as shown in Table 1:

[0085] Table 1 The parameter data table of the new sheet solid wood structural panel and several existing panels

[0086]

[0087] It can be seen from Table 1 that the novel sheet-like solid wood structural board prepared by the present invention has properties such as low density, high static bending strength, high elastic modulus, no formaldehyde e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com