Biological treatment method for removing sulfate radicals and COD in lead-zinc beneficiation wastewater

A technology for mineral processing wastewater and biological treatment, which is applied in mining wastewater treatment, biological water/sewage treatment, and water treatment parameter control. The effect of strong adaptability and strong industrial practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1. Configuration of sewage treatment system

[0042] 1. Build sewage treatment system hardware

[0043] The sewage storage tank, hydrolytic acidification tank, anaerobic reaction device, aerobic reaction device and secondary sedimentation tank are connected through pipelines.

[0044] 2. Cultivation and domestication of activated sludge

[0045] Obtain raw sludge from the urban sewage treatment plant, inoculate the raw sludge into the anaerobic sludge bed of the anaerobic reaction device, operate the treatment system, and control the sewage conditions entering the anaerobic reaction device: pH6.0~6.2, The carbon-sulfur ratio is 2:1, the temperature is 28-33 degrees Celsius, the SV is 30%, and the oxidation-reduction potential is -290--320. After 30 days of continuous operation, anaerobic sludge is obtained and put into formal use.

[0046] Aerobic sludge is obtained by aeration and domestication of the aforementioned anaerobic sludge, the conditions are ph7...

Embodiment 2

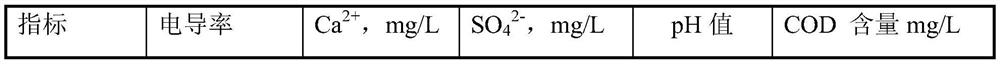

[0053] Taking the mineral processing wastewater discharged from a lead-zinc ore dressing plant as the treatment object, since the treated water sample is the production wastewater of the plant, when the production fluctuates, its chemical composition also has certain changes. The water quality analysis is shown in Table 1:

[0054] Table 1 embodiment 2 handles the water quality analysis table of water sample

[0055] sample name SO 4 2-

Ca 2+

pH value COD Lead-zinc beneficiation wastewater 838~1625 535~1024 7.03~8.09 237~446

[0056] Specifically, the biological treatment method for removing sulfate radicals and COD in the lead-zinc mineral processing wastewater in the present embodiment comprises the following steps:

[0057] Step 1: In order to make the ratio of the COD mass concentration to the sulfate radical mass concentration in the treated water sample about 2:1, the waste water enters the hydrolytic acidification tank equipped wi...

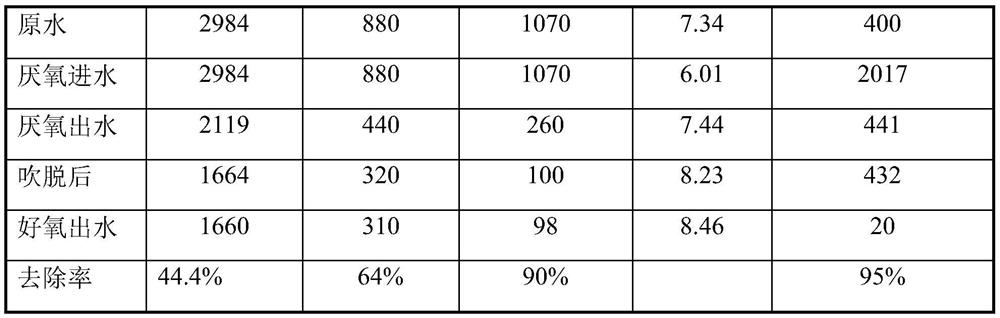

Embodiment 3

[0072] Taking the lead-zinc beneficiation wastewater discharged from a factory as the treatment object, it is obtained through testing that the COD in the wastewater is 1960mg / L, and the sulfate radical is 1100mg / L, which meets the condition that the ratio of the mass concentration of COD to the mass concentration of sulfate radical is N, so the treatment For this water sample, the hydrolysis and acidification step was omitted.

[0073] Specifically, the biological treatment method for removing sulfate radicals and COD in the lead-zinc mineral processing wastewater in the present embodiment comprises the following steps:

[0074] Step 1, monitoring and judging the mass concentration ratio of COD and sulfate in the lead-zinc mineral processing wastewater, that is, obtaining the above water quality detection and judging steps, which will not be repeated here.

[0075] Step 3: Add lime water to the water inlet tank containing the lead-zinc mineral processing wastewater in step 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com