Optical control device and method for coating thickness

An optical control and laser technology, which is applied in sputtering coating, vacuum evaporation coating, ion implantation coating, etc., can solve the problems of misjudgment of coating termination conditions, demanding stability requirements, complex systems, etc., and achieve reduced stability and rotation position detection accuracy requirements, to achieve real-time optimization, the effect of a simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

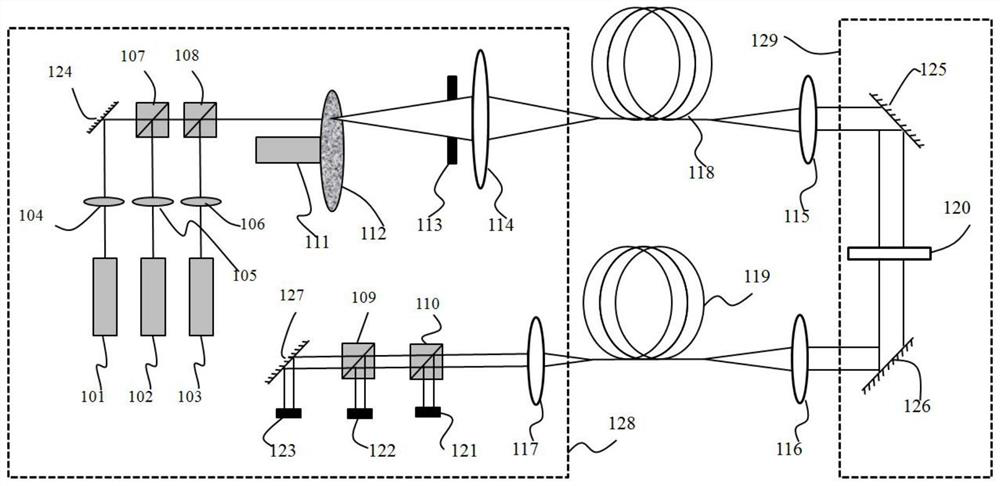

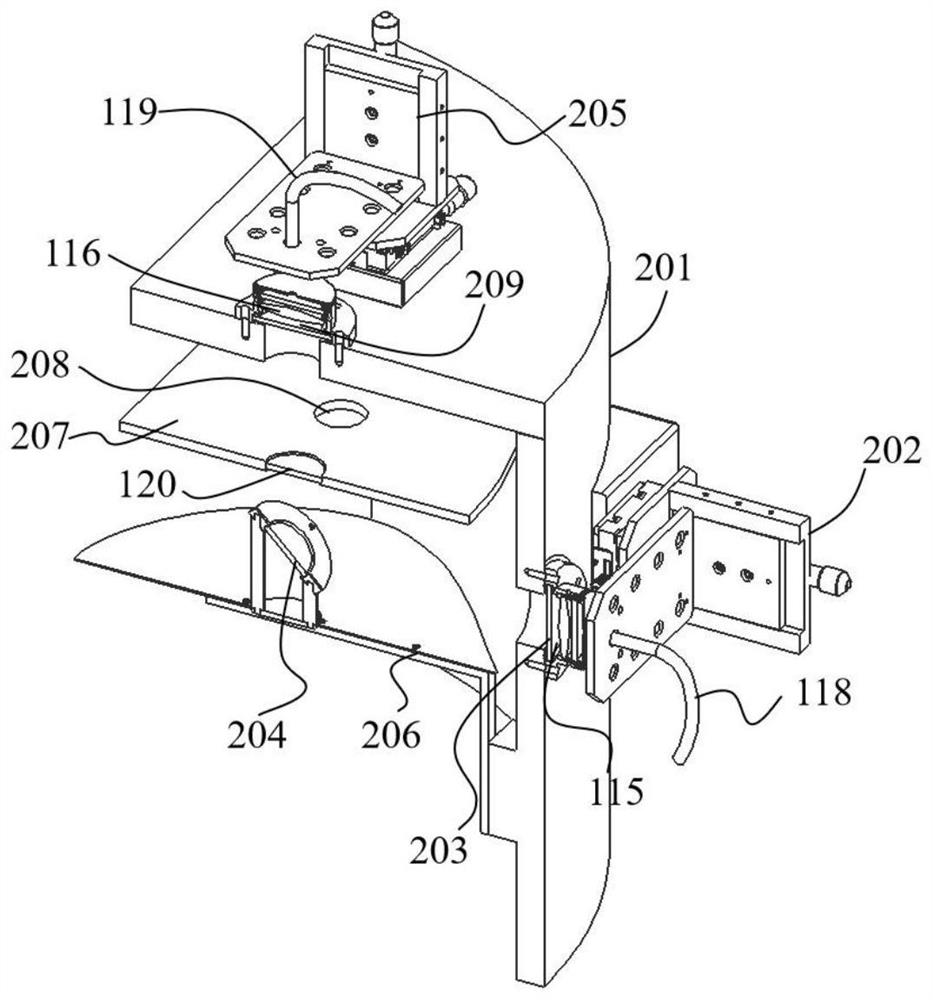

[0039] figure 1 Shows the structure of a coating thickness optical control device, the coating thickness optical control device includes three different wavelengths of the first laser 101, the second laser 102 and the third laser 103, the first lens group 104, the second lens group 105 and the third lens group 106, the first light splitting element 107, the second light splitting element 108, the third light splitting element 109 and the fourth light splitting element 110, the drive motor 111, the diffusion plate 112, the diaphragm 113, the first lens 114, the second light splitting element Two lens 115, the third lens 116 and the fourth lens 117, the first multimode fiber 118 and the second multimode fiber 119, the optical control test piece 120, the first optical power meter 121, the second optical power meter 122 and the third Optical power meter 123, optional first planar reflective element 124, second planar reflective element 125, third planar reflective element 126, and...

Embodiment 2

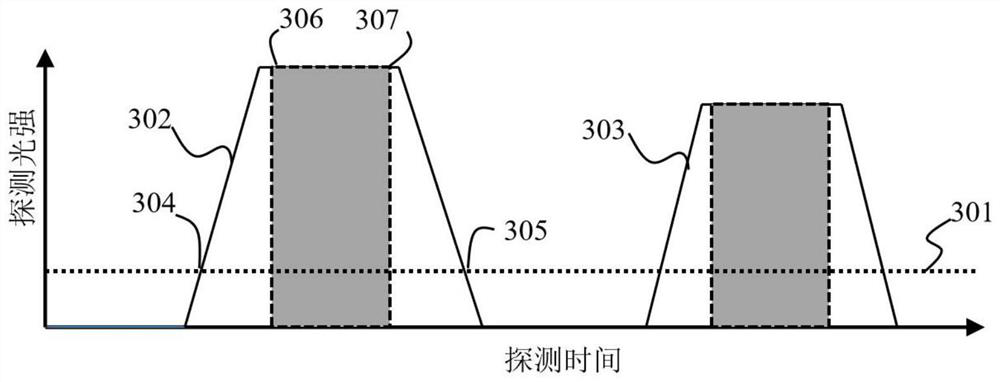

[0064] The following examples illustrate the method of using the coating thickness optical control device to control coating thickness and realize optical interference multilayer coating. by Ta 2 o 5 As a high refractive index material, SiO 2 As a low refractive index material, it should be noted that the high refractive index and low refractive index here are only relative concepts, and do not limit a certain refractive index or refractive index range to low or high refractive index. The double-sided polished fused silica glass substrate is used as a light control test piece to realize Figure 4 In the shown wavelength range of 400nm-1000nm, both the transmittance curve 401 and the reflectance curve 402 are close to the function of a 50% spectroscopic film. This implementation example only introduces the working mode of the thickness control device shown, and other various film systems can be realized by using the steps and methods.

[0065] Ta 2 o 5 film, SiO 2 The re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com