A tooth profile optimization method for a harmonic reducer rigid wheel

A technology of harmonic reducer and optimization method, applied in design optimization/simulation, geometric CAD, special data processing applications, etc., can solve the problem of poor transmission effect of rigid wheel tooth profile and flexible wheel tooth profile, and it is difficult to simulate the motion trajectory of flexible wheel , interference and other problems, to achieve the effect of optimized tooth shape, high meshing transmission efficiency and small backlash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

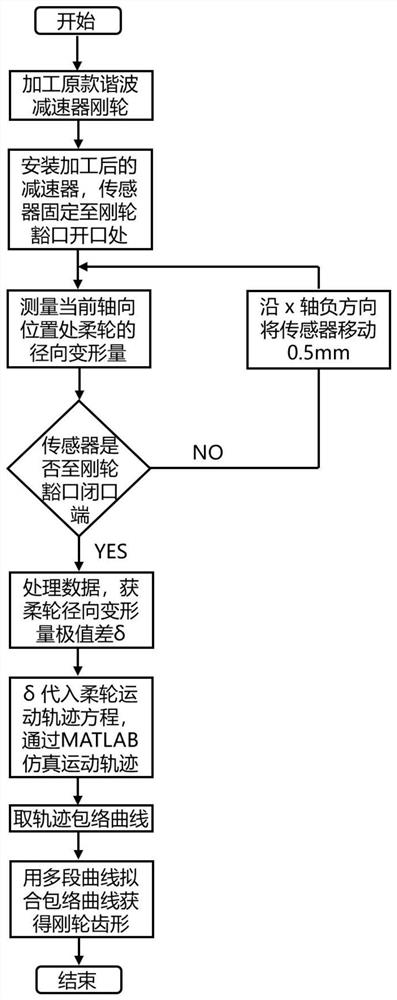

[0033] like figure 2 As shown in the figure, a method for optimizing the tooth profile of a rigid wheel of a harmonic reducer specifically includes the following steps:

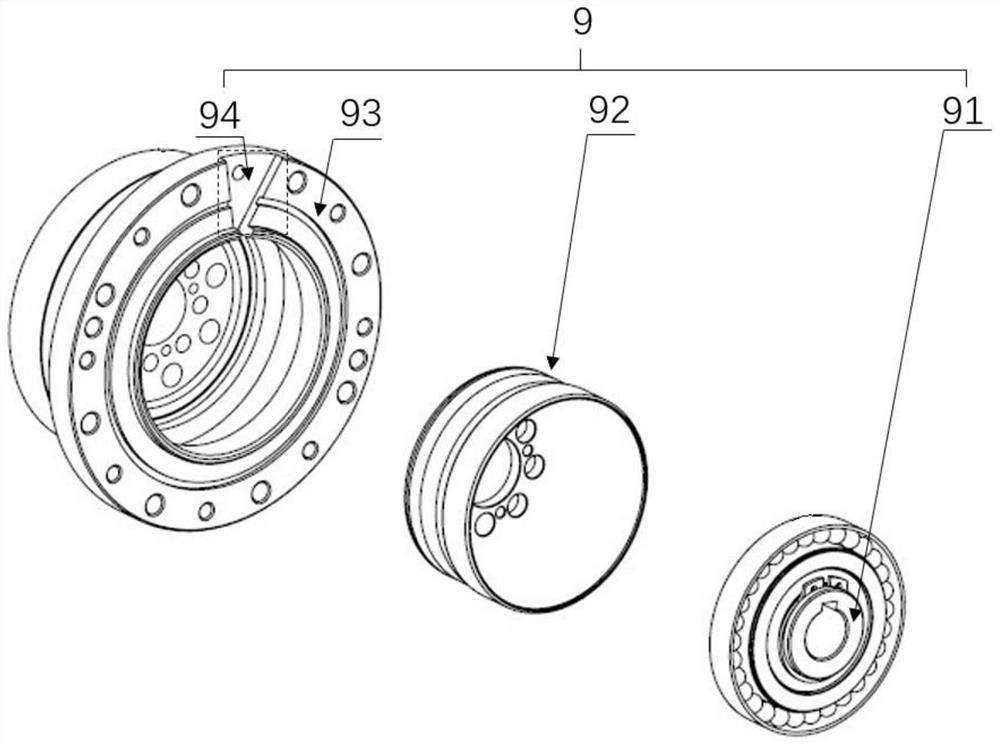

[0034] The first step is to form an observation gap 94 with a specific shape on the rigid wheel 93 of the harmonic reducer 9 by secondary cutting processing;

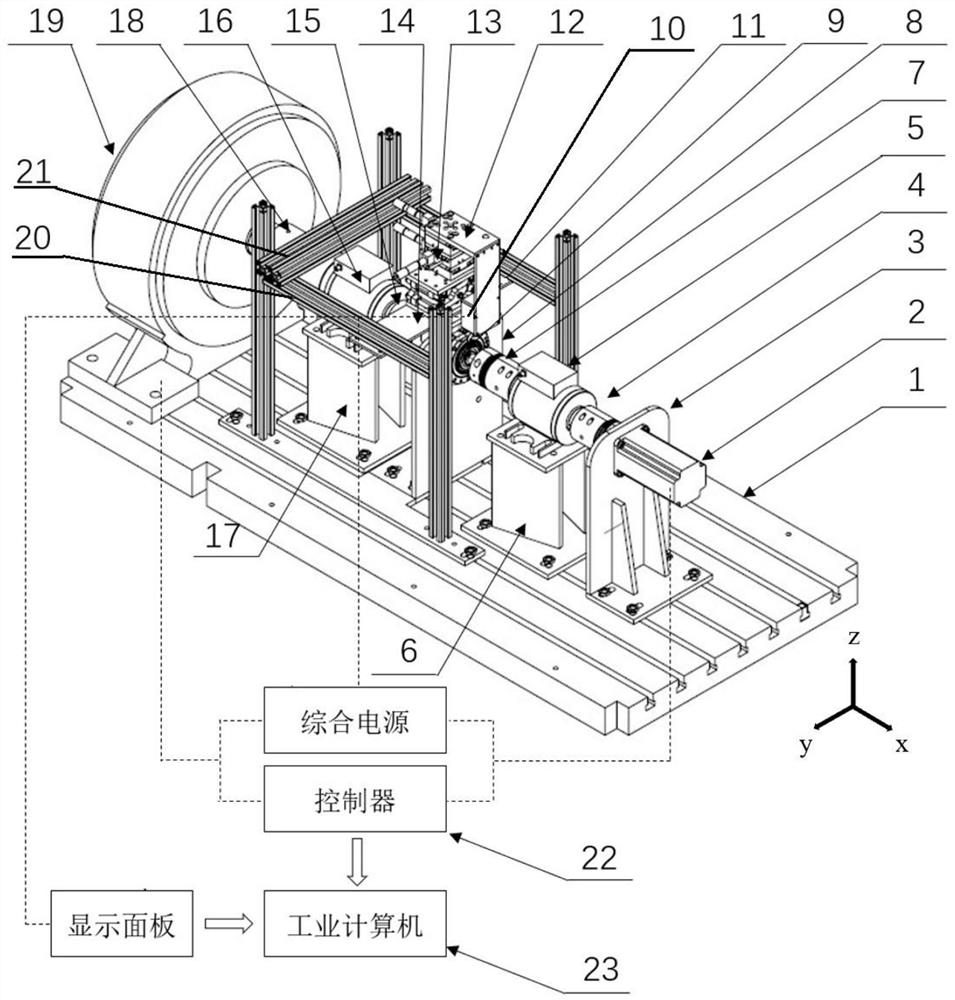

[0035] In the second step, the machined harmonic reducer 9 is installed into the measuring device for the radial deformation of the flex wheel teeth of the harmonic reducer. Turn on the device switch, calibrate the position of the point laser displacement sensor 10 through the three-degree-of-freedom displacement stage 13, so that the point laser displacement sensor 10 can measure normally, and is fixed on the open end of the rigid wheel observation gap 94;

[0036] In the third step, the AC servo motor 2 is controlled to rotate by the controller 22, and the point laser displacement sensor 10 records data and then transmits and stores it to the indus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com