Out-of-pile collection, split charging and retention system for reactor melts

A technology for melts and reactors, used in reactors, cooling devices, emergency protection devices, etc., can solve the problems of large disputes in the estimation of heat flux density, and it is not suitable for high-power reactor types, so as to shorten the cooling time and occupy limited space. , the effect of high resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention are introduced below in conjunction with accompanying drawings:

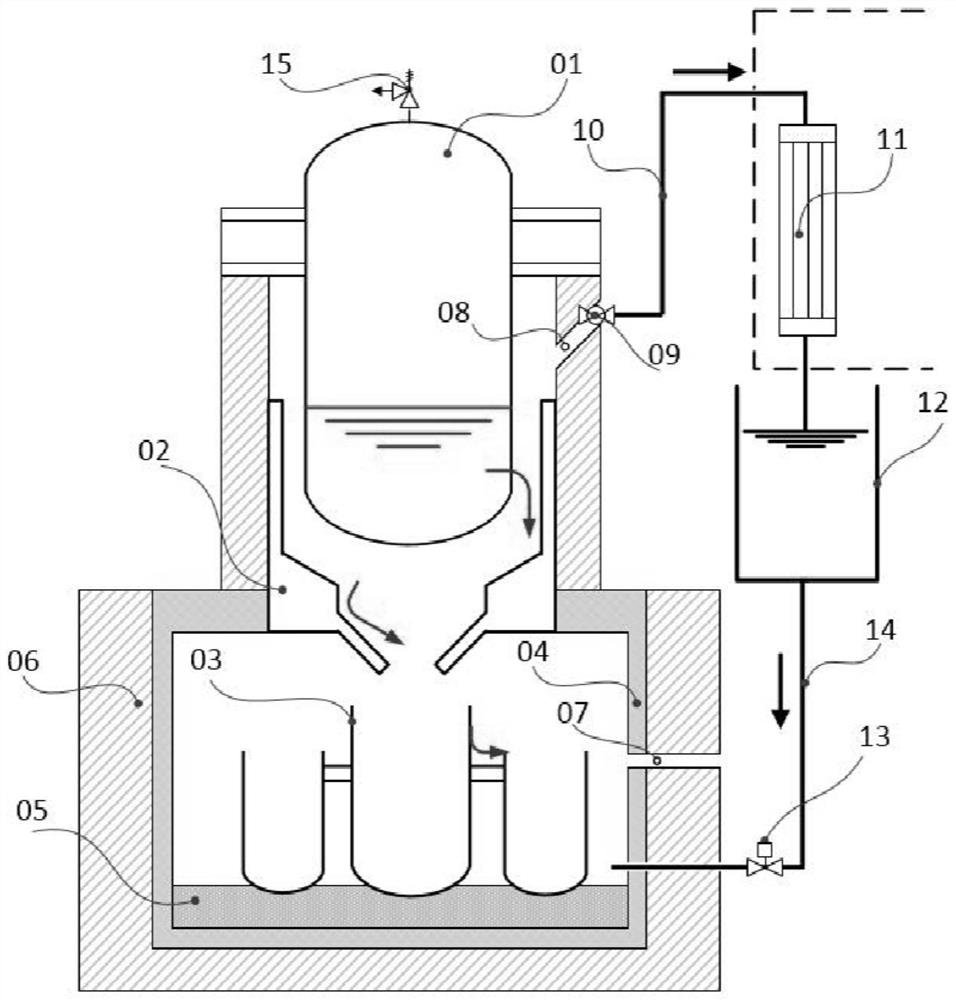

[0033] like figure 1 As shown, the present invention provides a system for collecting, distributing and detaining reactor melt outside the reactor, including a melt collecting device 02, a multi-crucible dispersing and detaining device 03 and a cooling circuit.

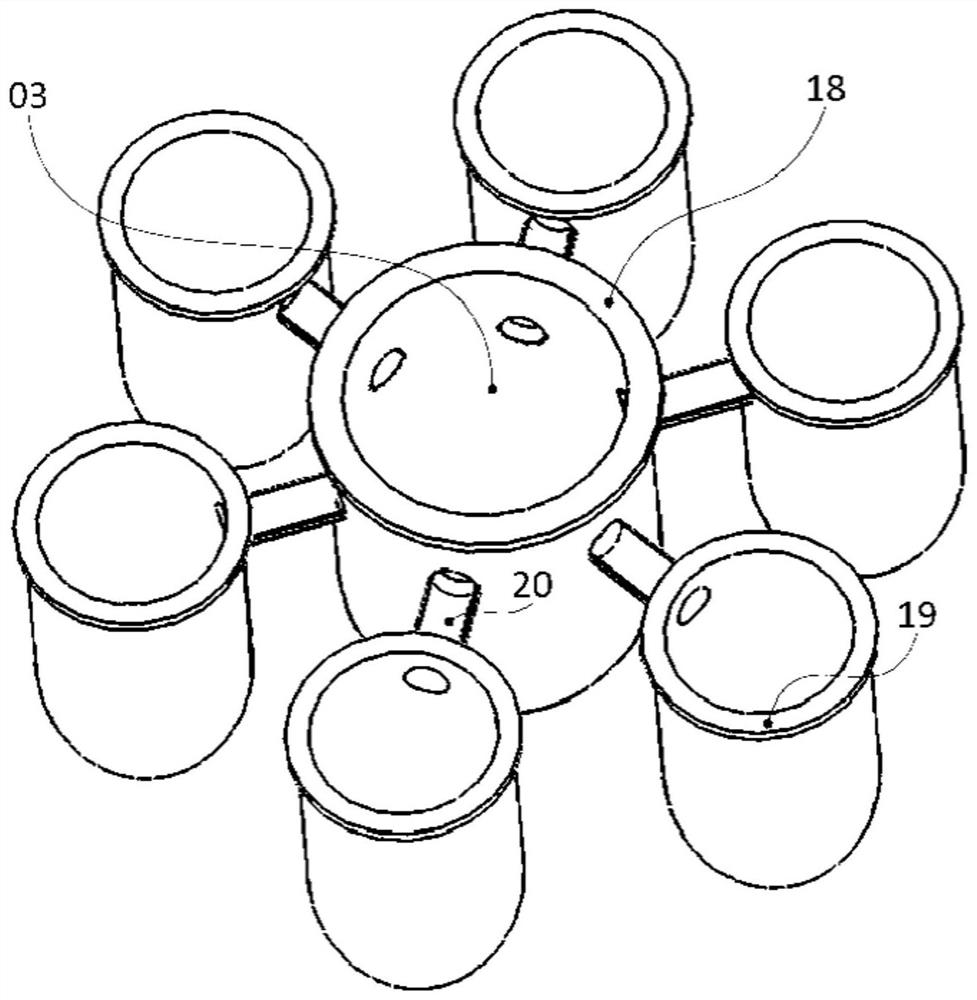

[0034] In order to better collect the molten material that may splash in all directions after the accident, the molten material collection device 02 is installed on the vertical support inner wall of the pressure vessel 01, including the inclined surface and the shroud that are opposite to the lower head of the pressure vessel 01. Said shroud draws in toward the center. like figure 2 As shown, the melt collection device 02 has a two-layer structure, including a lower heat insulation layer 17 and a surface lubricating layer 16; the surface lubricating layer 16 is a hematite layer, which can ensure the smooth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com