Manufacturing method of micro light-emitting diode display device

A technology of light-emitting diodes and display devices, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., and can solve the problems of unable to meet the spacing of electronic components, moving tens of thousands or even hundreds of thousands, and large quantities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

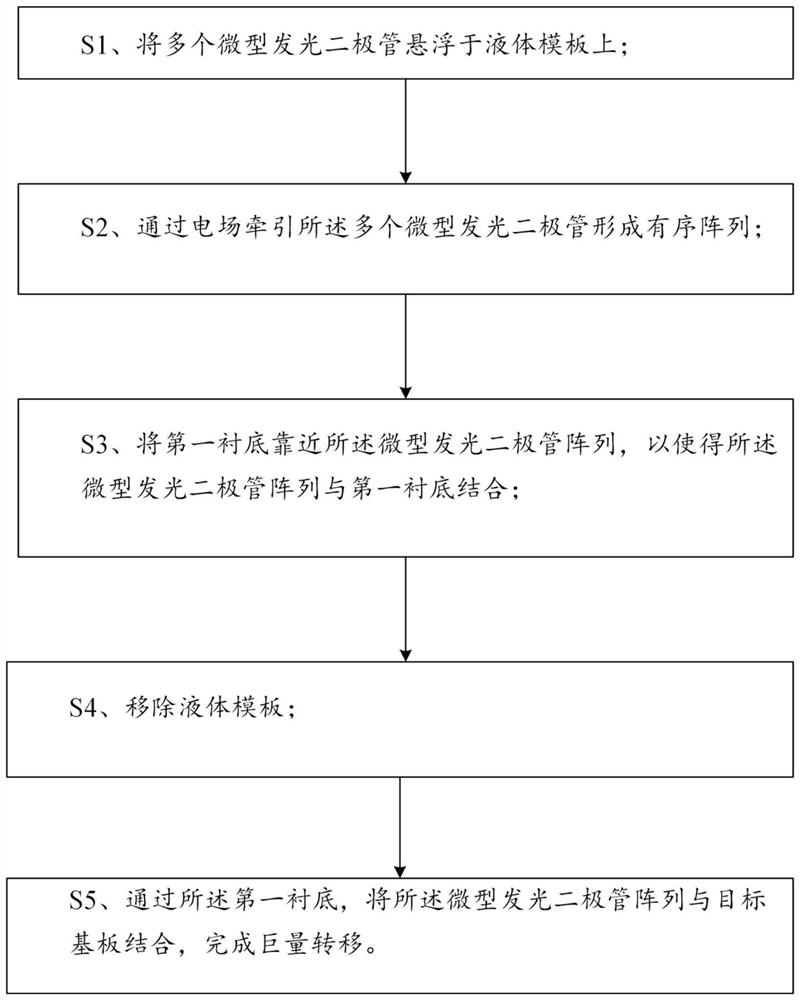

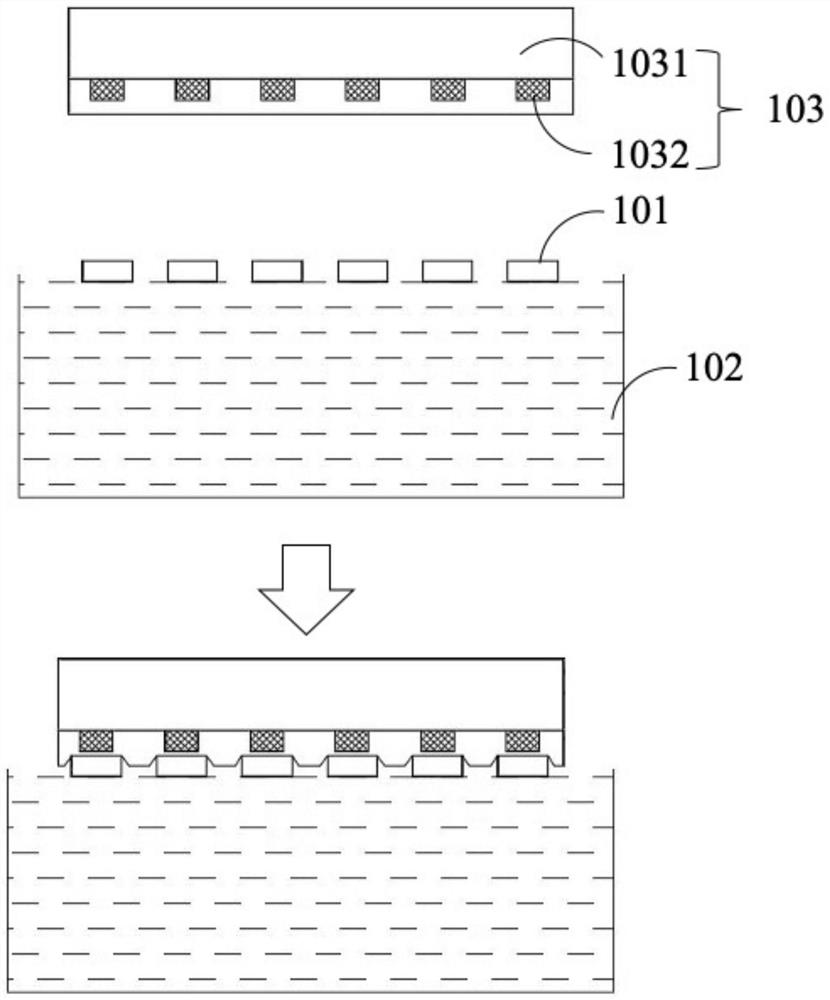

[0035] First, through Figure 1-3 , the method for manufacturing the micro light emitting diode display device according to Embodiment 1 of the present invention will be described. A technical solution adopted in this embodiment is to provide a method for manufacturing a micro light-emitting diode display device, which includes:

[0036] S1. Suspend a plurality of micro light emitting diodes 101 on the liquid template 102, the density of the liquid template 102 ethylene glycol is greater than that of the micro light emitting diodes 101, and the liquid template 102 is expandable. The potentials of the plurality of micro LEDs 101 control their mutual equilibrium distances.

[0037]S2. Pulling the plurality of micro light emitting diodes 101 to form an ordered array by an electric field.

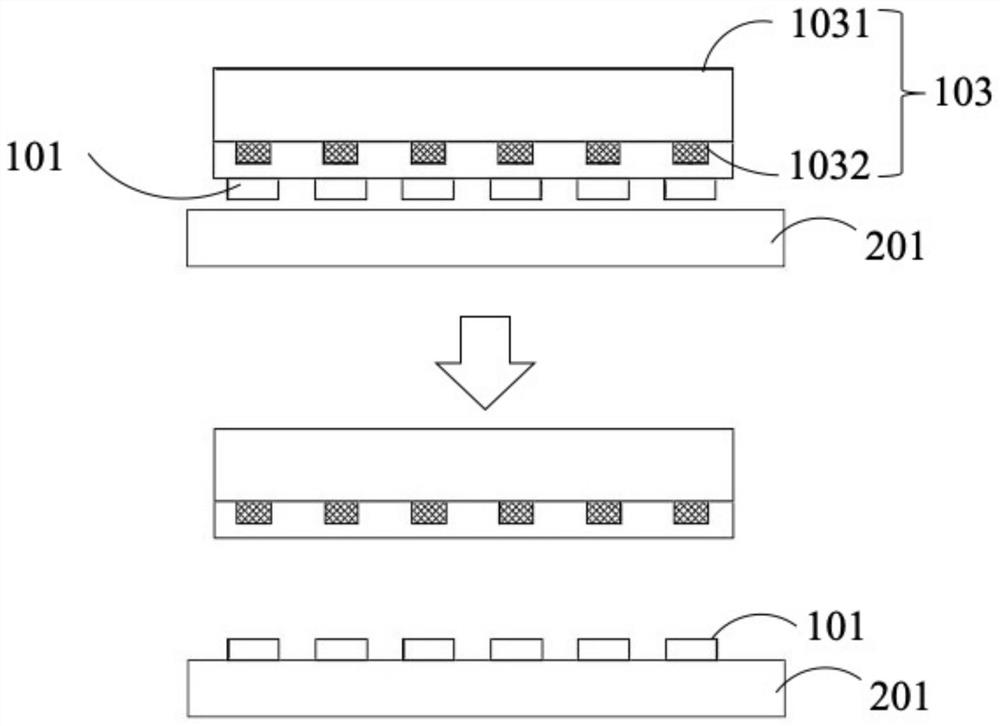

[0038] S3, bringing the first substrate 103 close to the array of micro light emitting diodes 101, so that the array of micro light emitting diodes 101 is combined with the first substrate 10...

Embodiment 2

[0048] Please refer to Figure 4 , is a schematic diagram of step S3 of the manufacturing method of the micro light emitting diode 101 display device according to the second embodiment of the present invention. Only the differences between Embodiment 2 and Embodiment 1 will be described below, and the similarities will not be repeated here.

[0049] The liquid template 102 is dimethyl sulfoxide, and its density is equal to that of the micro LED 101 .

[0050] Before step S1, the micro LEDs 101 are fixed on a first solid template. The manufacturing method of the micro light emitting diode 101 display device further includes removing the first solid template.

[0051] In step S4, the method of removing the liquid template 102 is UV light evaporation.

Embodiment 3

[0053] Please refer to Figure 5 , is a schematic diagram of step S3 of the manufacturing method of the micro light emitting diode 101 display device according to the third embodiment of the present invention. In the following, only the differences between Embodiment 3 and Embodiment 1 will be described, and the similarities will not be repeated here.

[0054] The liquid template 102 is tetrahydrofuran, and its density is smaller than that of the micro LED 101 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com